Cogging torque separation method of permanent magnet synchronous motor under load condition

A cogging torque and load-carrying technology, which is applied in the field of electrical engineering, can solve problems such as the complexity of cogging torque calculation, and achieve good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The implementation steps of this embodiment are as follows:

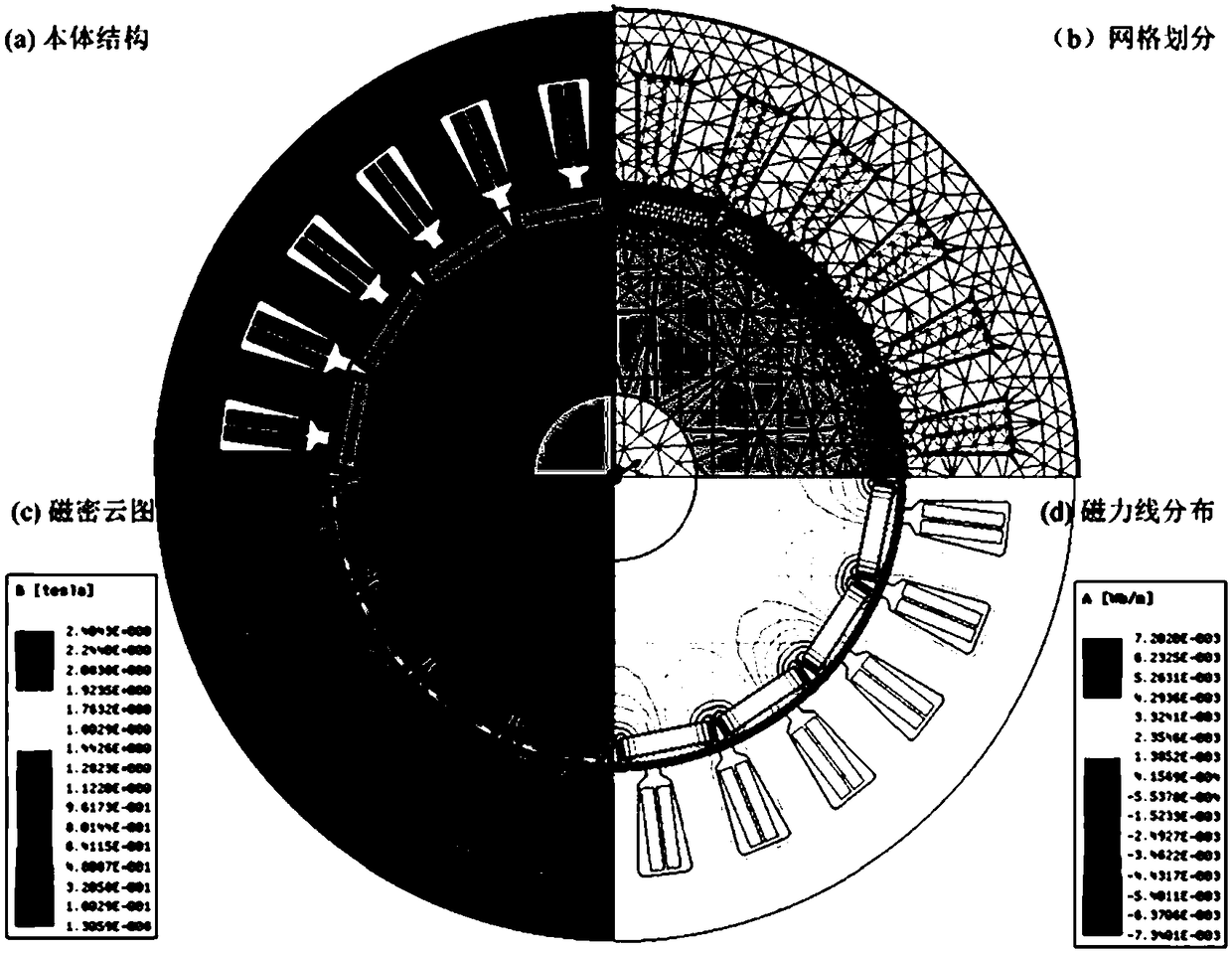

[0051] (1) This example uses a two-dimensional model of a 24-slot, 16-pole "one" type embedded permanent magnet synchronous motor. In the finite element analysis software Ansoft, set various parameters according to the following table, and get the following figure 1 The 2D static model shown.

[0052]

[0053] (2) According to the three-phase current of the motor under the condition of load operation, the stator winding current i which is the same as the actual situation is set by the finite element analysis software a =15cos(400πt), The unit is A.

[0054] (3) According to the rotating speed of the motor under load operation, then set the same motor running speed n=1500 as the actual situation through the finite element analysis software, and the unit is r / min;

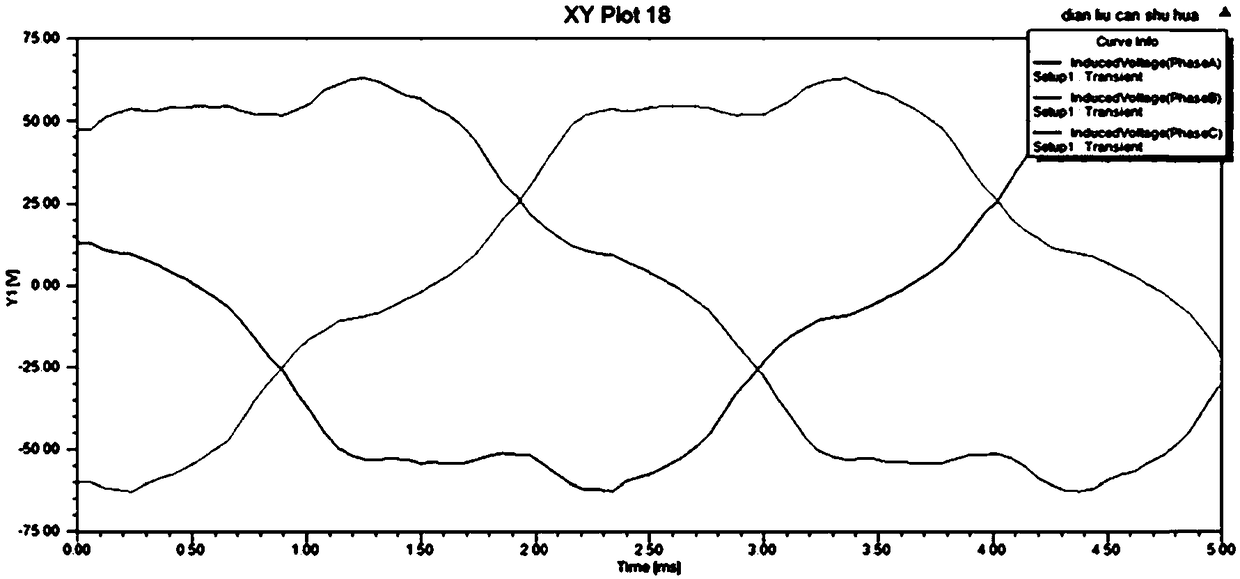

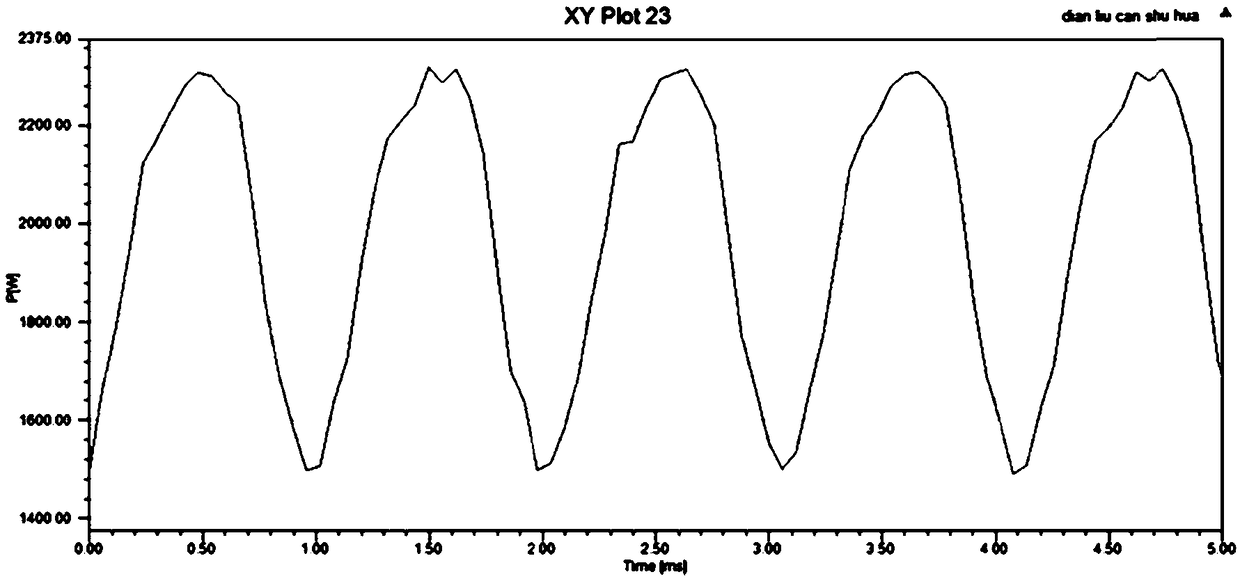

[0055] (4) In the solver of the finite element analysis software, the back electromotive force e of the three-phase winding is obtained a 、...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com