Automatic seedling tray feeding mechanism based on fully automatic pot seedling transplanter

A transplanting machine, fully automatic technology, applied in the field of agricultural machinery, can solve the problems of restricting the promotion and use of fully automatic transplanting machines, limiting the transplanting speed of transplanting machines, and high manual labor intensity, etc., to achieve simple and reliable mechanical transmission, The effect of reducing labor costs and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

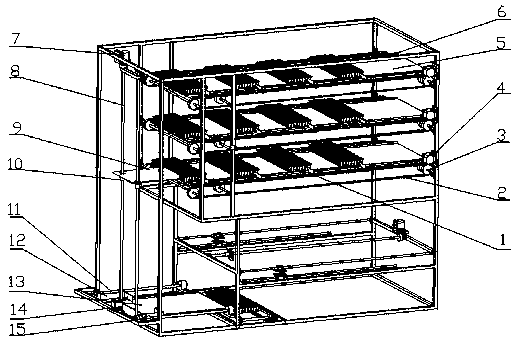

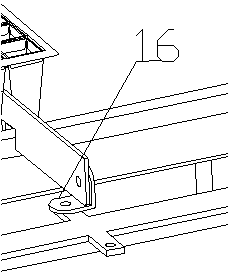

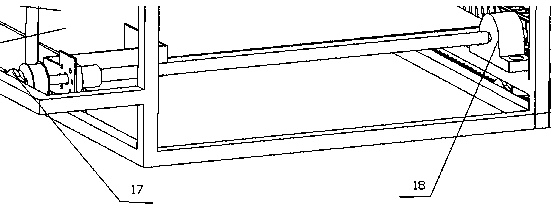

[0017] The basic principle of the present invention is: through the precise control of the speed of the stepping motor (4), stepping motor (7) and stepping motor (14), the horizontal pushing plate (1) of the seedling tray and the vertical feeding of the seedling tray can be realized. The coordinated movement of the plate (9) and the seedling plate push plate (12) completes the work of feeding the seedling plate; the movement of the seedling plate horizontal push plate (1) is driven by the curved plate chain, and the seedling plate is vertically fed to the plate ( 9) The movement with the seedling push plate (12) is driven by the vertical lead screw nut (10) and the horizontal lead screw nut (15) respectively, and the vertical lead screw nut (10) is driven by the vertical lead screw (8) The rotation of itself realizes the up and down movement on the vertical lead screw (8), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com