A permanent magnet double disc brake and a braking method thereof

A brake and permanent magnet technology, applied in the direction of brake type, axial brake, brake actuator, etc., can solve the problems of magnetic flux leakage, permanent magnet retarder magnetic flux leakage, etc., to reduce wear, avoid magnetic leakage, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

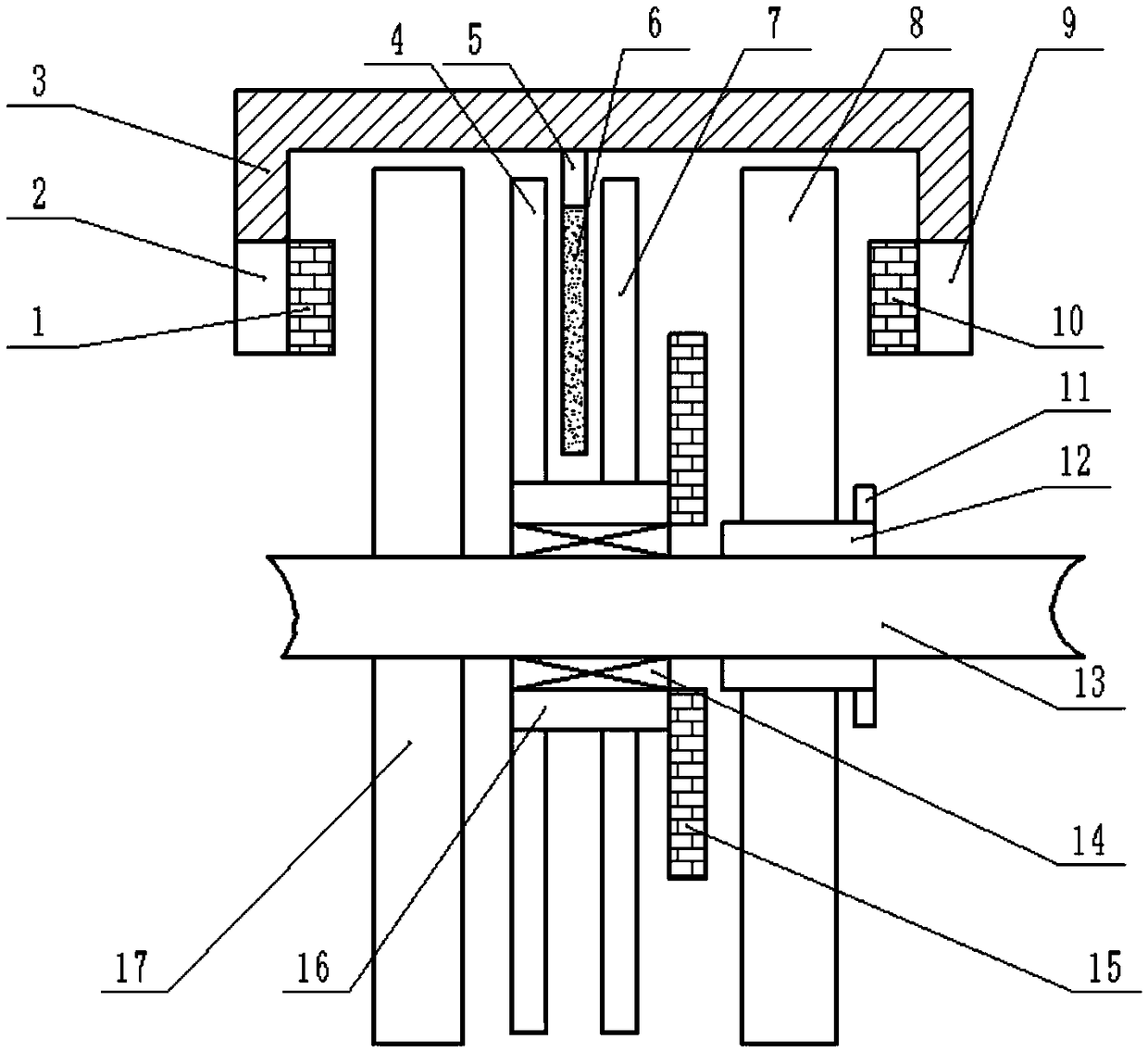

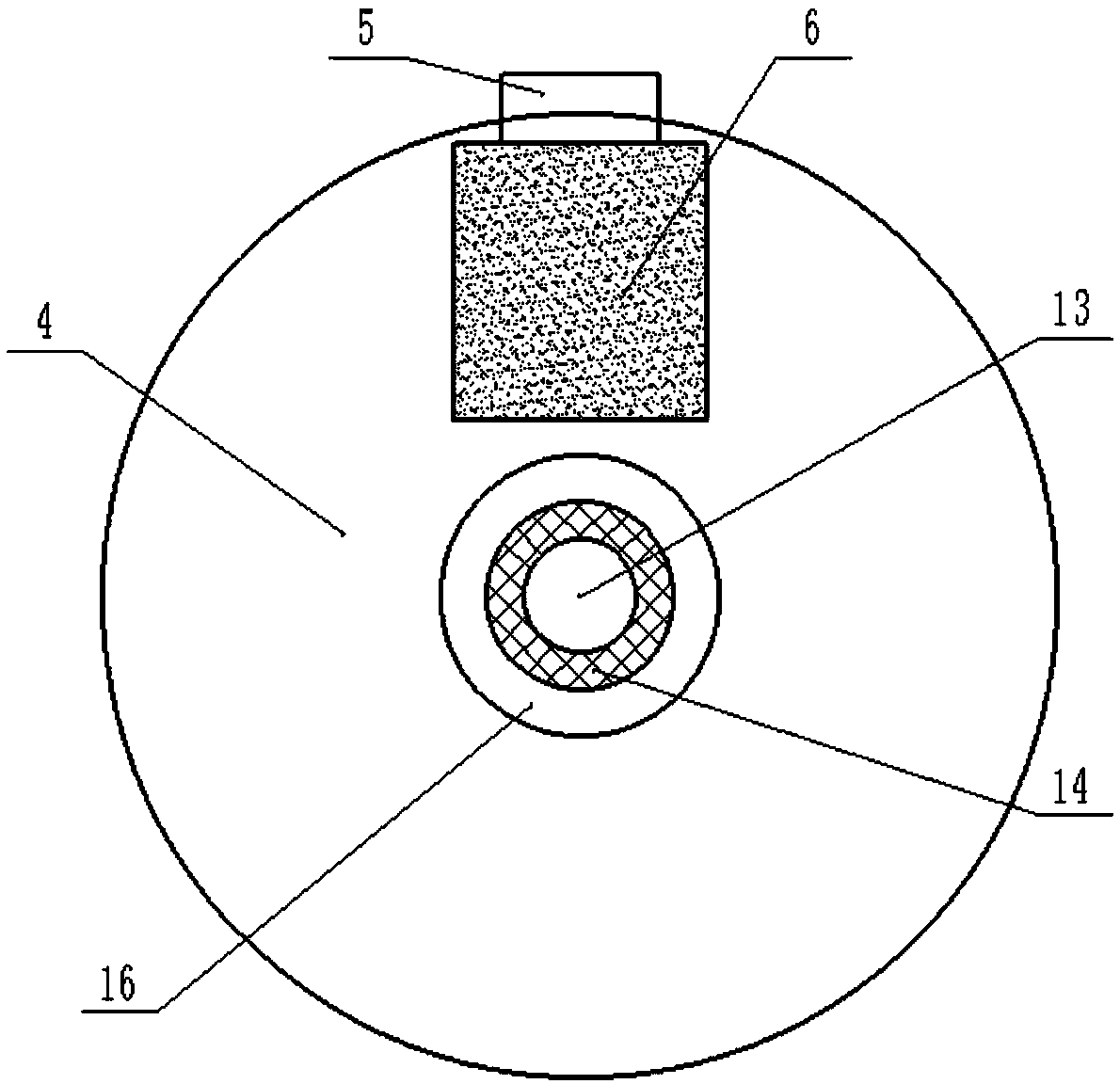

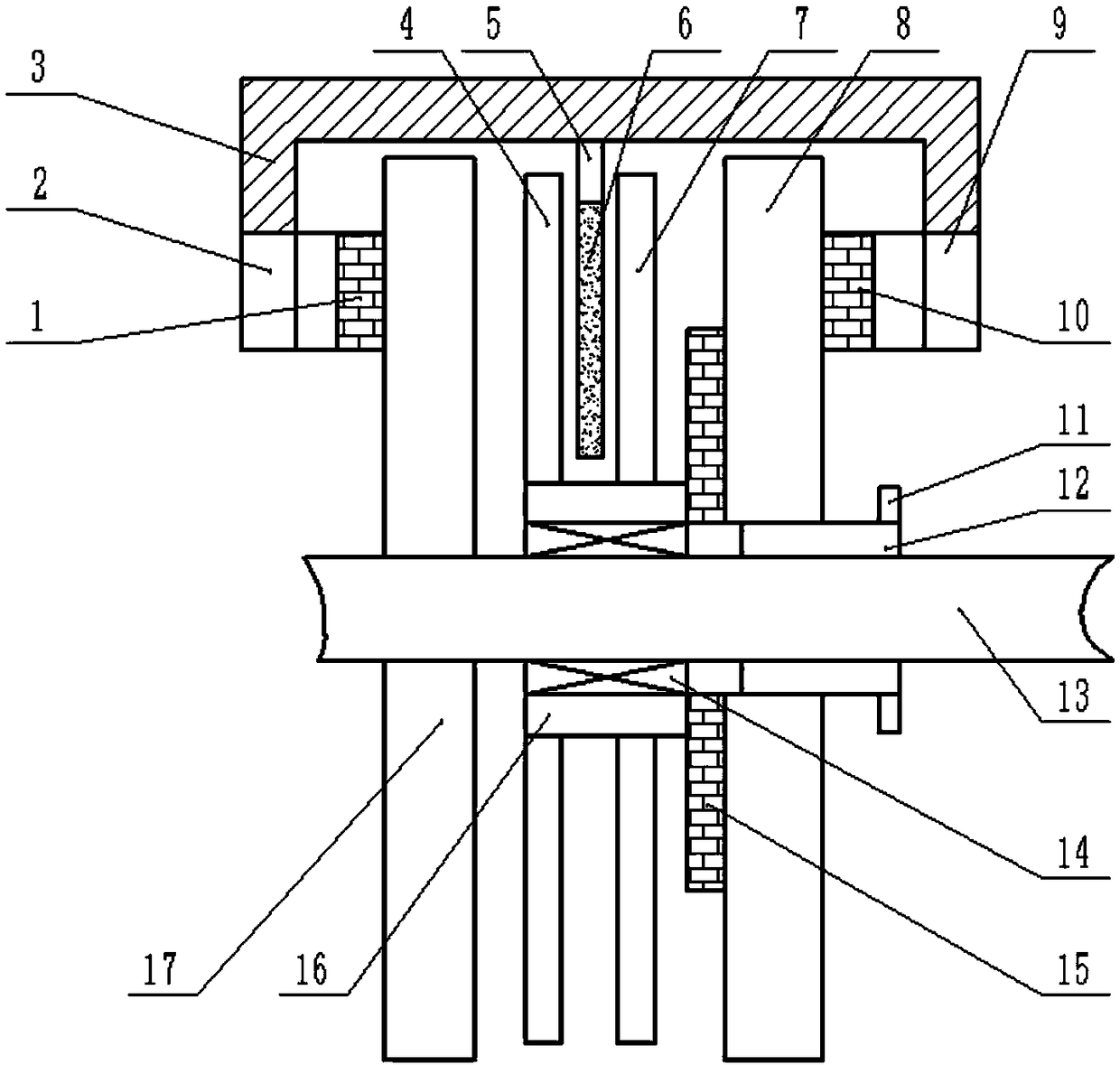

[0026] The following will be described in detail in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

[0027] as attached figure 1 , 2 As shown, a kind of permanent magnet double disc brake of the present invention comprises inner brake disc 8, outer brake disc 17, connecting shaft 13, sliding gear 12, bearing 14, permanent magnet ring 11, double disc brake caliper 3, permanent magnet The connecting block 5 and the permanent magnet brake assembly; the outer brake disc 17, the bearing 14 and the sliding gear 12 are coaxially installed on the connecting shaft 13 in sequence from left to right, and the connecting shaft 13 is connected with the wheel hub and the axle shaft on the vehicle body; The moving disc 8 can be slidably installed on the sliding gear 12, and the connecting shaft 13, the outer brake disc 17, the bearing 14, the sliding gear 12, and the inner brake disc 8 are coaxial.

[0028] The permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com