Intelligent control method for temperature in kiln of gas industry

A furnace temperature and intelligent control technology, applied in the field of control, can solve the problems of lack of science, increase the difficulty of shuttle kiln temperature control, affect the stability of product quality, etc., and achieve the effect of reducing the interference of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

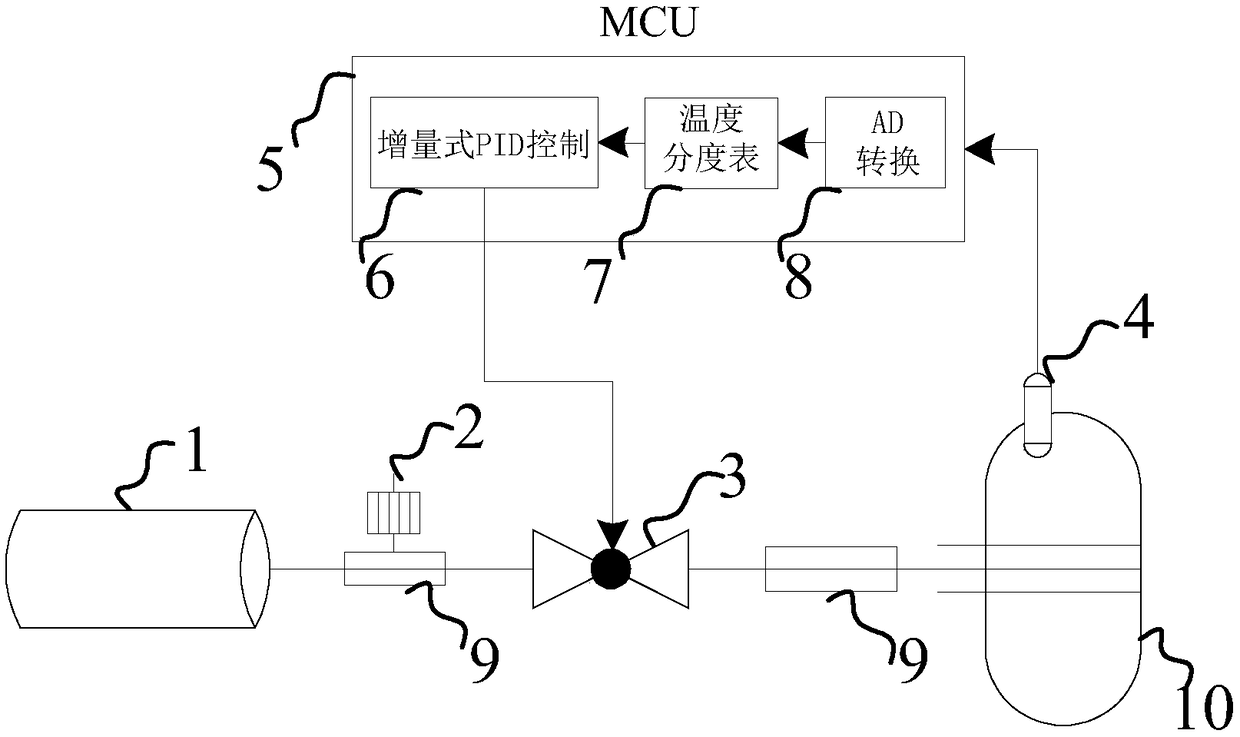

[0038] Such as figure 1 As shown, the gas industrial kiln control system includes: gas supply 1, front pressure sensor 2, electric proportional valve 3, thermocouple temperature sensor 4, kiln controller (MCU) 5, incremental PID control module 6, temperature Index meter 7, AD conversion module 8, gas pipeline 9 and shuttle kiln 10, supply gas 1 passes through front pressure sensor 2, electric proportional valve 3, and is transmitted to shuttle kiln 10 by gas pipeline 9.

[0039] The front-end pressure sensor collects the pressure value of the source gas; feeds back the pressure value of the supply gas 1. The premise of temperature control of the gas industrial kiln is that the pressure value of the supply gas 1 is greater than the minimum pressure of the kiln firing production gas.

[0040] The thermocouple temperature sensor 4 is located in the shuttle kiln 10, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com