Method for detecting adhesive force of offset ink of laser cigarette case

A detection method and adhesion technology, applied in the direction of measuring devices, instruments, and mechanical devices, can solve the problems of large deviation of detection results, inaccurate detection, instability, etc., achieve simple instruments, solve detection difficulties, and low detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

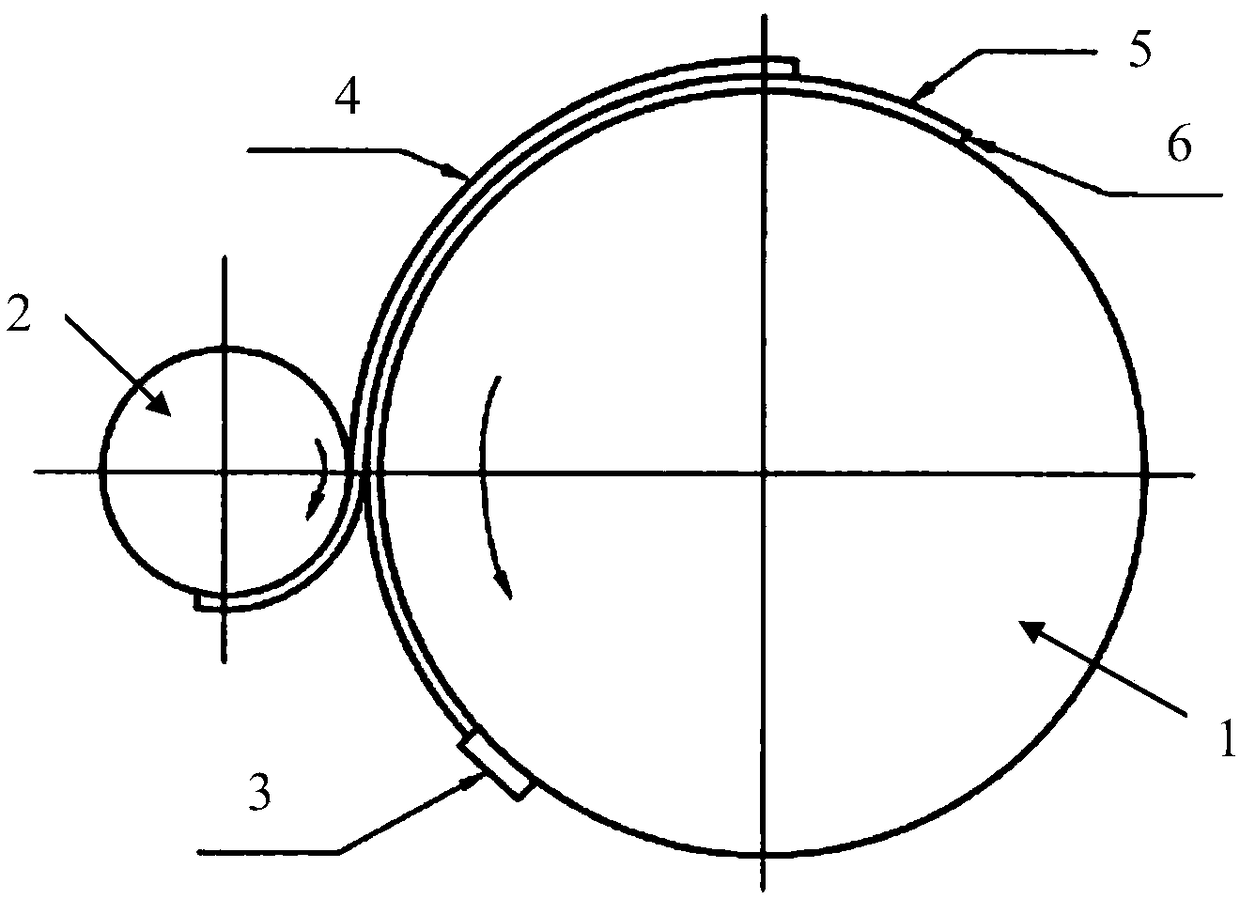

Method used

Image

Examples

Embodiment 1

[0048] (1) Since the spot color yellow is the ink with the worst adhesion in the implementation case products, this embodiment selects the printing surface of the special yellow for adhesion testing. The spot color yellow used in this case is made by Hanghua UV offset printing ink and Limei The special yellow color prepared by special offset printing UV ink, the printing material is laser horizontal beam light column medium composite paper, take the test product sample and cut it into a sample with a length of 20cm and a width of 5cm for use.

[0049] (2) Paste the sample with 3M600 adhesive tape, pay attention to the smooth paste without leaving air bubbles, and pay attention to leave a small section at the other end for peeling test.

[0050] (3) The sample is rolled, the rolling speed is 400mm / M, the number of rolling is 3 times, and the length of each rolling is 150mm.

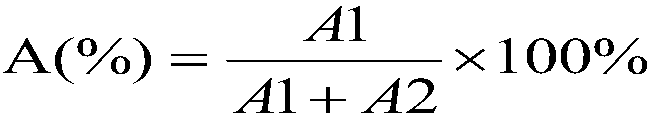

[0051] (4) Leave the sample after rolling for 5 minutes, and use a neutral pen to draw the outline of t...

Embodiment 2

[0056] (1) Since the spot color yellow is the ink with the worst adhesion in the implementation case products, this embodiment selects the printing surface of the spot color yellow for adhesion testing. The spot color yellow used in this case is the spot color yellow ink of Hanghua UV offset printing , the printing material is composite paper with laser stripe light column medium, take the test product sample and cut it into a sample with a length of 20cm and a width of 5cm for use.

[0057] (2) Paste the sample with 3M810 adhesive tape, pay attention to the smooth paste without leaving air bubbles, and pay attention to leave a small section at the other end for easy peeling.

[0058] (3) Roll the sample, the rolling speed is 200mm / M, the number of rolling times is 2 times, and the length of each rolling is 150mm.

[0059] (4) Leave the sample after rolling for 10 minutes, and use a neutral pen to draw the outline of the tape, so that it is convenient to use millimeter grid pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com