Pesticide spraying bucket for unmanned aerial vehicle and operation method thereof

A technology of pesticide spraying and unmanned aerial vehicles, which is applied in applications, aircraft parts, devices for catching or killing insects, etc., can solve problems such as low efficiency of pesticide spraying operations, personal injury, and high labor intensity of operators, and achieve guaranteed Aesthetics, guaranteed effectiveness, and the effect of expanding the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

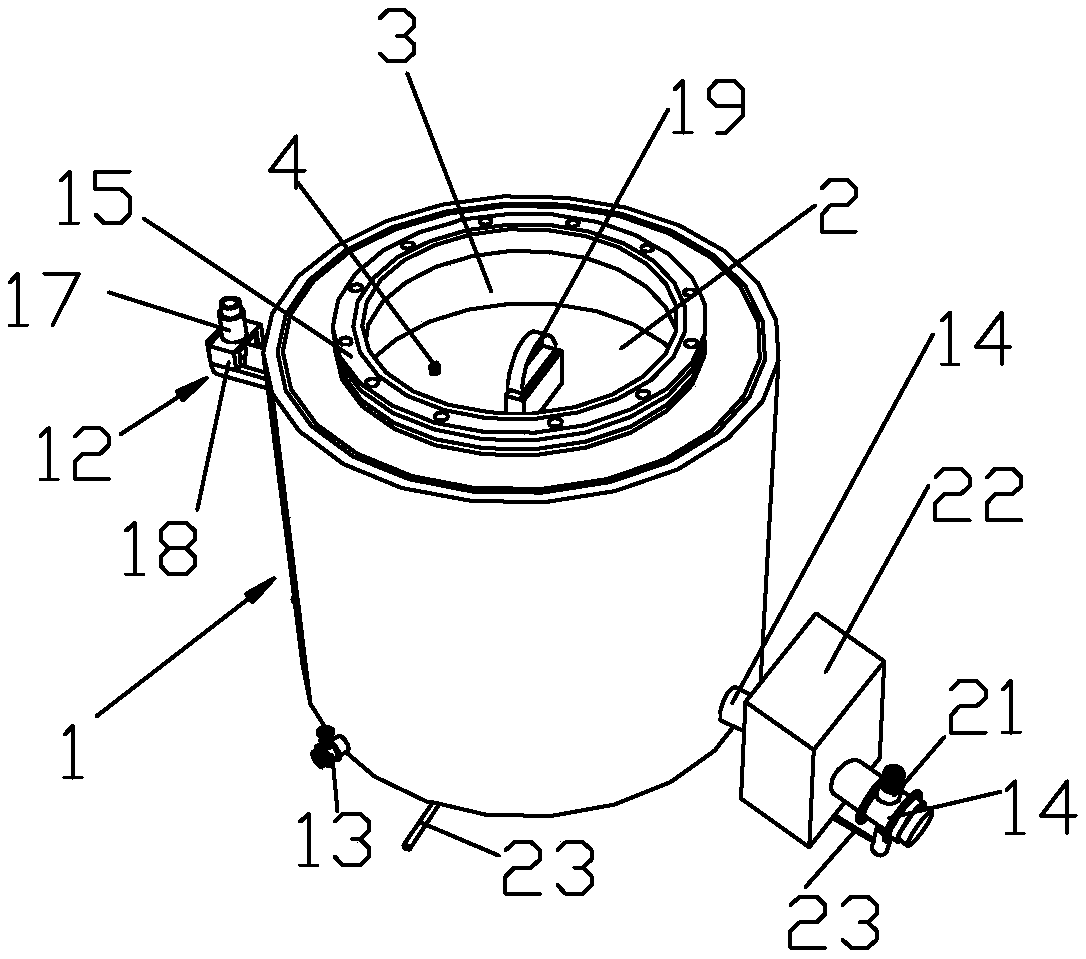

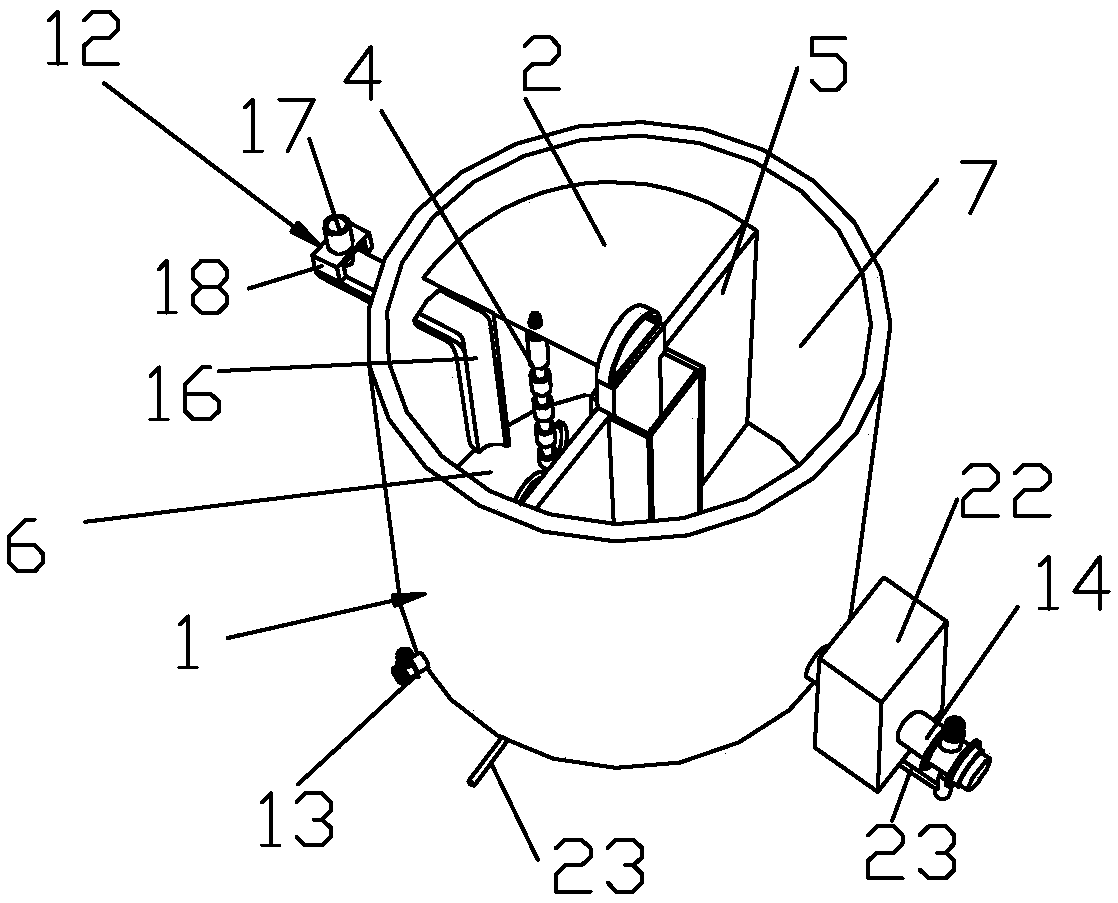

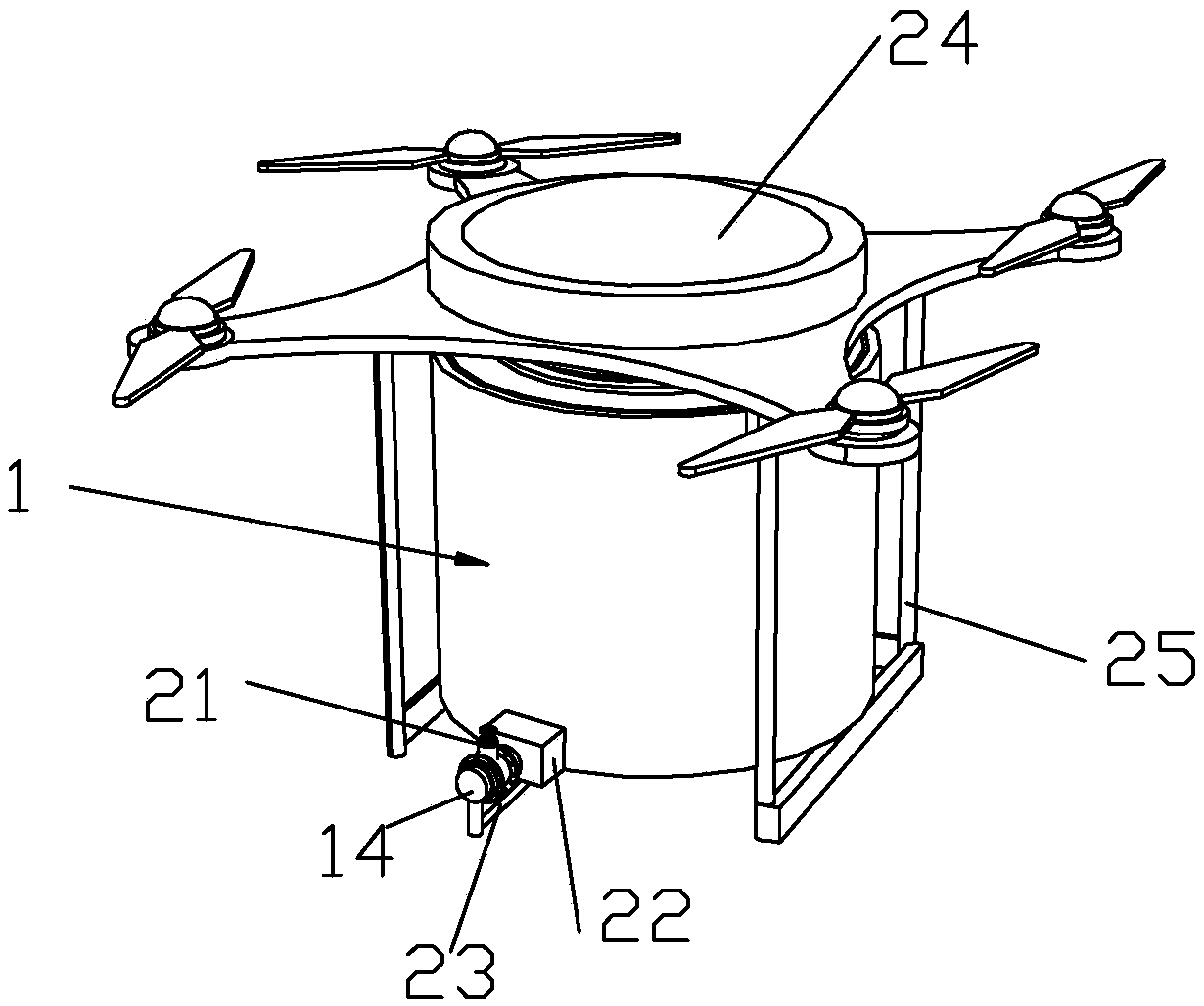

[0038] Such as Figure 1 to Figure 5 As shown, in order to solve the above technical problems, the present invention adopts the following technical scheme: a pesticide spray barrel for unmanned aerial vehicles, comprising a barrel body 1 and a cover plate 2, the inside of the barrel body 1 is provided with a partition plate 5, the partition plate 5 Divide the barrel body 1 into a stirring chamber 6 and an operating chamber 7. A cover plate 2 is installed on the partition plate 5. The size of the cover plate 2 matches the size of the barrel body 1. The left side of the cover plate 2 is provided with a stirring 4, the agitator 4 extends into the barrel body 2, a groove 8 is arranged on the partition plate 5, and a water retaining plate 9 is installed in the groove 8, and the water retaining plate 9 is clamped with the separating plate 5, and the separating plate 5 A limit block 10 is set on one side of the mixing chamber 6, the length of the limit block 10 is longer than the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com