Mildew preventive for foodstuff warehousing and preparation method therefor

An antifungal agent and storage technology, which is applied in the field of grain storage, can solve the problems of affecting health, troublesome time, etc., and achieves the effect of mild smell, low cost and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

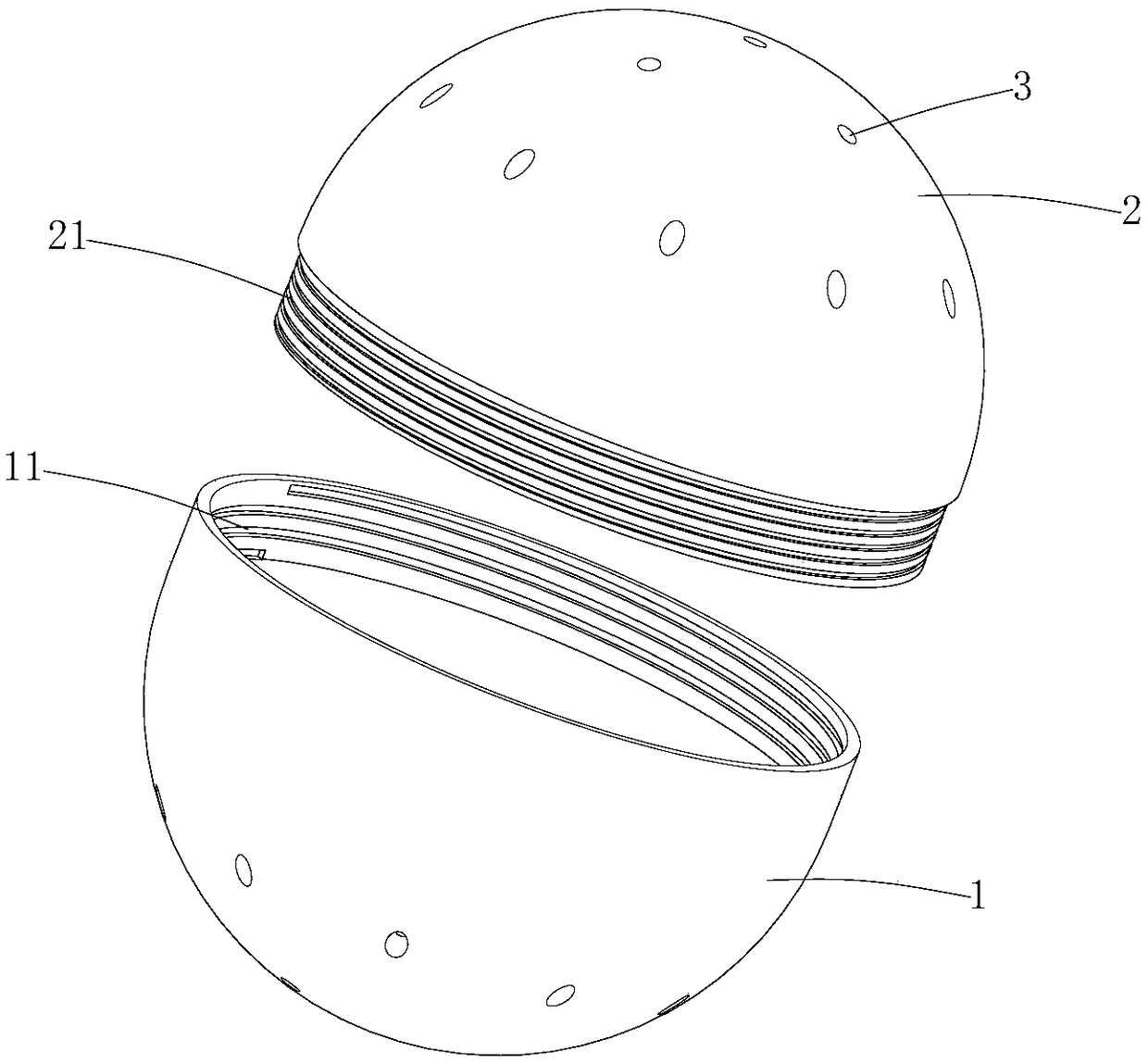

Image

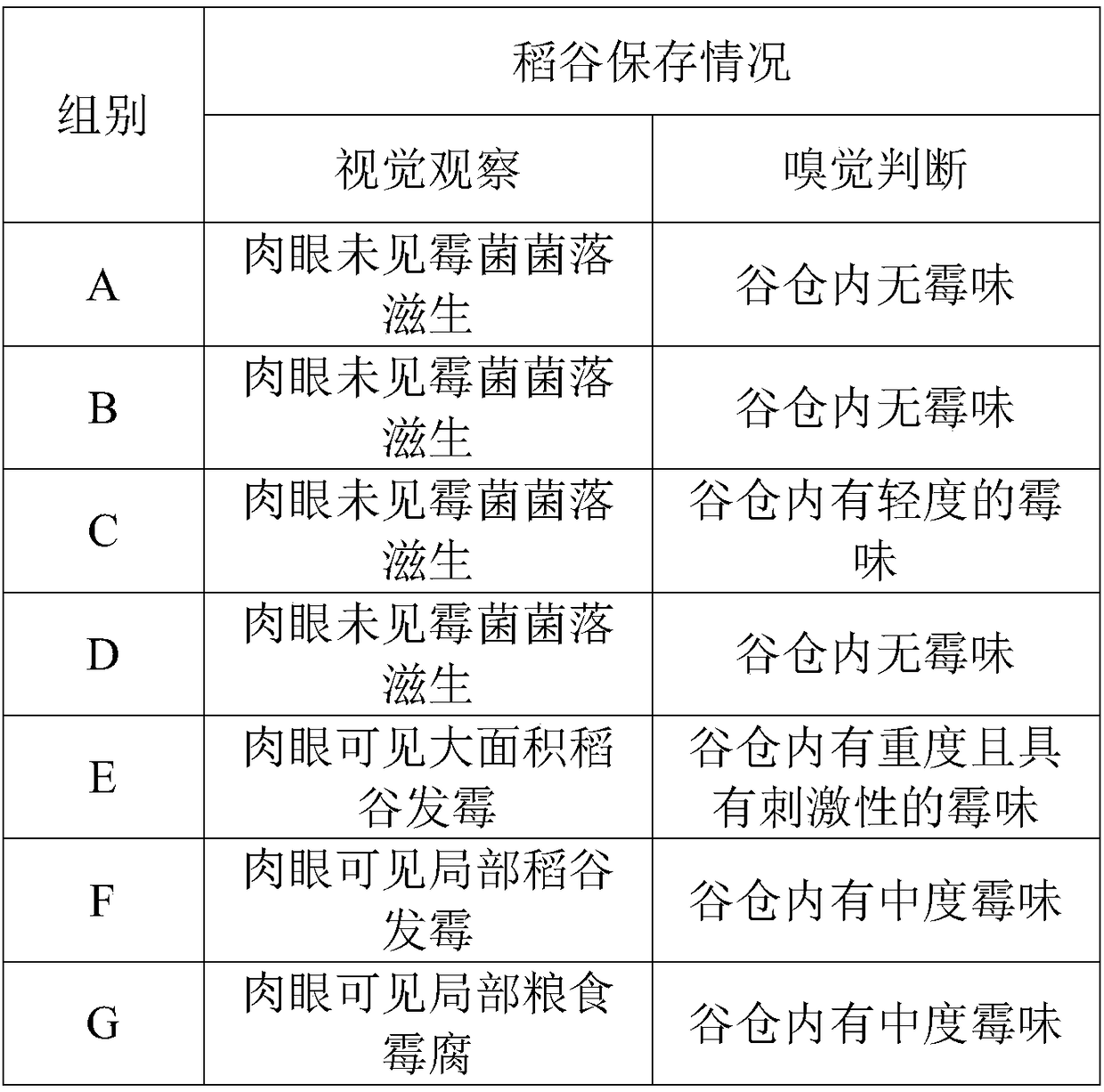

Examples

Embodiment 1

[0025] This embodiment provides a technical solution:

[0026] An antifungal agent used in grain storage, in parts by weight, the antifungal agent comprises the following components: 25 parts of Yurui essential oil, 18 parts of garlic essential oil, 24 parts of scorpion essential oil, 13 parts of Haitouhong essential oil 12 parts of forsythia essential oil, 13 parts of skunk essential oil, 15 parts of tomato stem and leaf essential oil, 8 parts of geranium essential oil, 7 parts of mugwort leaf essential oil, 5 parts of cinnamon essential oil, 7 parts of plumflower essential oil, 6 parts of scallion essential oil, 9 parts of Huang Jing essential oil, 7 parts of peppermint essential oil, 7 parts of ebony essential oil, 5 parts of Zhuru essential oil, 15 parts of orange peel essential oil, 6 parts of pepper essential oil, 4 parts of mustard essential oil, 7 parts of nano silver powder, 18 parts of sea mud and 12 parts of volcanic ash .

Embodiment 2

[0028] This embodiment provides a technical solution:

[0029] An antifungal agent used in grain storage, in parts by weight, the antifungal agent comprises the following components: 20 parts of Yurui essential oil, 15 parts of garlic essential oil, 15 parts of scorpion essential oil, 10 parts of Haitouhong essential oil 10 parts of forsythia essential oil, 10 parts of stinky vegetable essential oil, 10 parts of tomato stem and leaf essential oil, 5 parts of geranium essential oil, 5 parts of mugwort leaf essential oil, 3 parts of cinnamon essential oil, 5 parts of plumflower essential oil, 5 parts of scallion essential oil, 7 parts of Huang Jing essential oil, 6 parts of peppermint essential oil, 5 parts of ebony essential oil, 3 parts of Zhuru essential oil, 10 parts of orange peel essential oil, 5 parts of pepper essential oil, 3 parts of mustard essential oil, 5 parts of nano silver powder, 15 parts of sea mud and 10 parts of volcanic ash .

Embodiment 3

[0031] This embodiment provides a technical solution:

[0032] An antifungal agent used in grain storage, in parts by weight, the antifungal agent comprises the following components: 26 parts of Yurui essential oil, 23 parts of garlic essential oil, 22 parts of Strigata essential oil, 13 parts of Haitouhong essential oil 12 parts of forsythia essential oil, 13 parts of skunk essential oil, 15 parts of tomato stem and leaf essential oil, 6 parts of geranium essential oil, 8 parts of mugwort essential oil, 5 parts of cinnamon essential oil, 7 parts of plumflower essential oil, 6 parts of scallion essential oil, 10 parts of Huang Jing essential oil, 7 parts of peppermint essential oil, 6 parts of ebony essential oil, 5 parts of Zhuru essential oil, 20 parts of orange peel essential oil, 6 parts of pepper essential oil, 4 parts of mustard essential oil, 8 parts of nano silver powder, 18 parts of sea mud and 13 parts of volcanic ash .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com