Fungus strain and fertilizer mixing device in edible mushroom plantation equipment

A mixing device and edible fungus technology, applied in the field of machinery, can solve problems such as laboriousness and troublesome operation, and achieve the effect of ensuring uniformity and improving planting quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

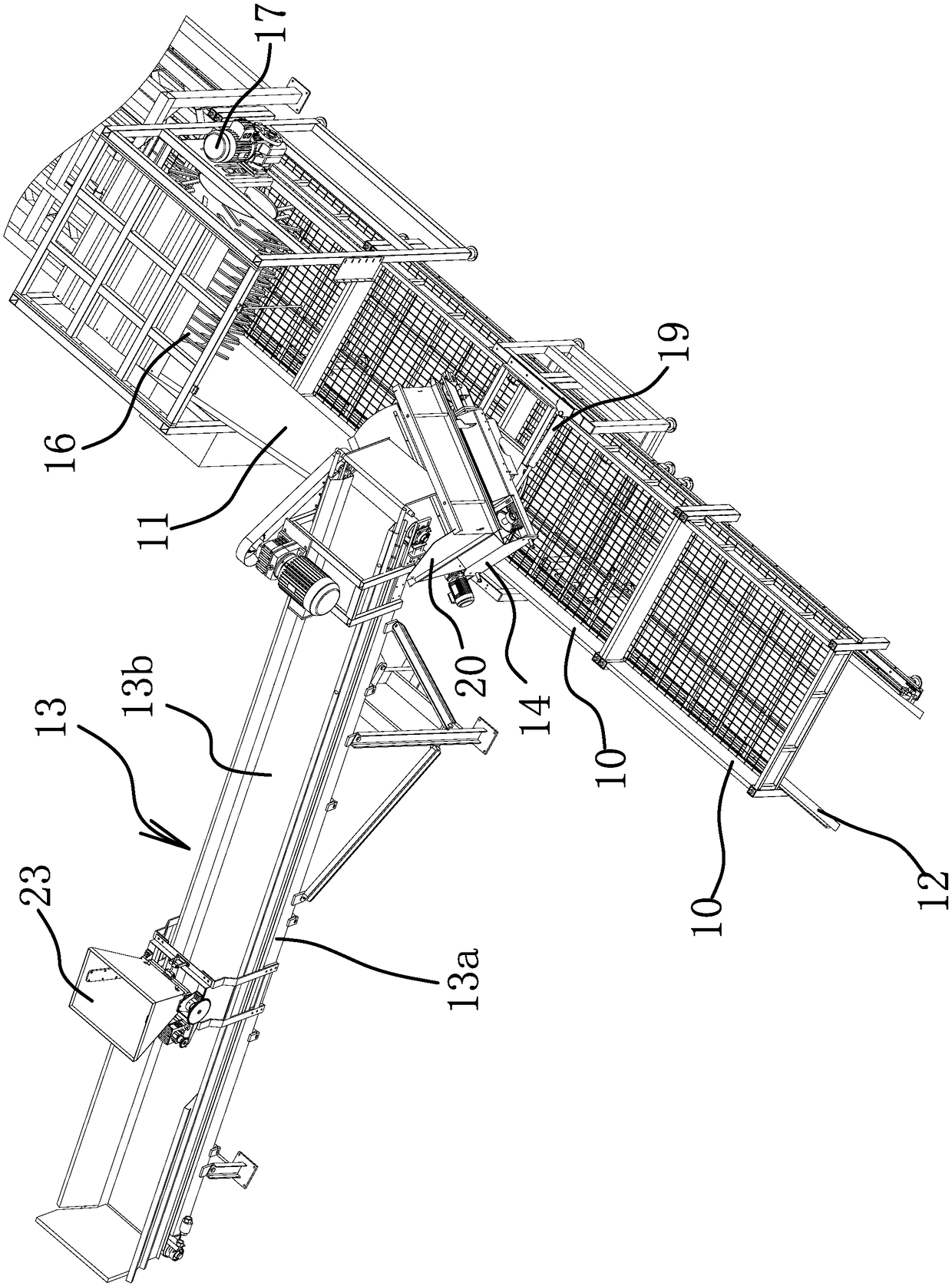

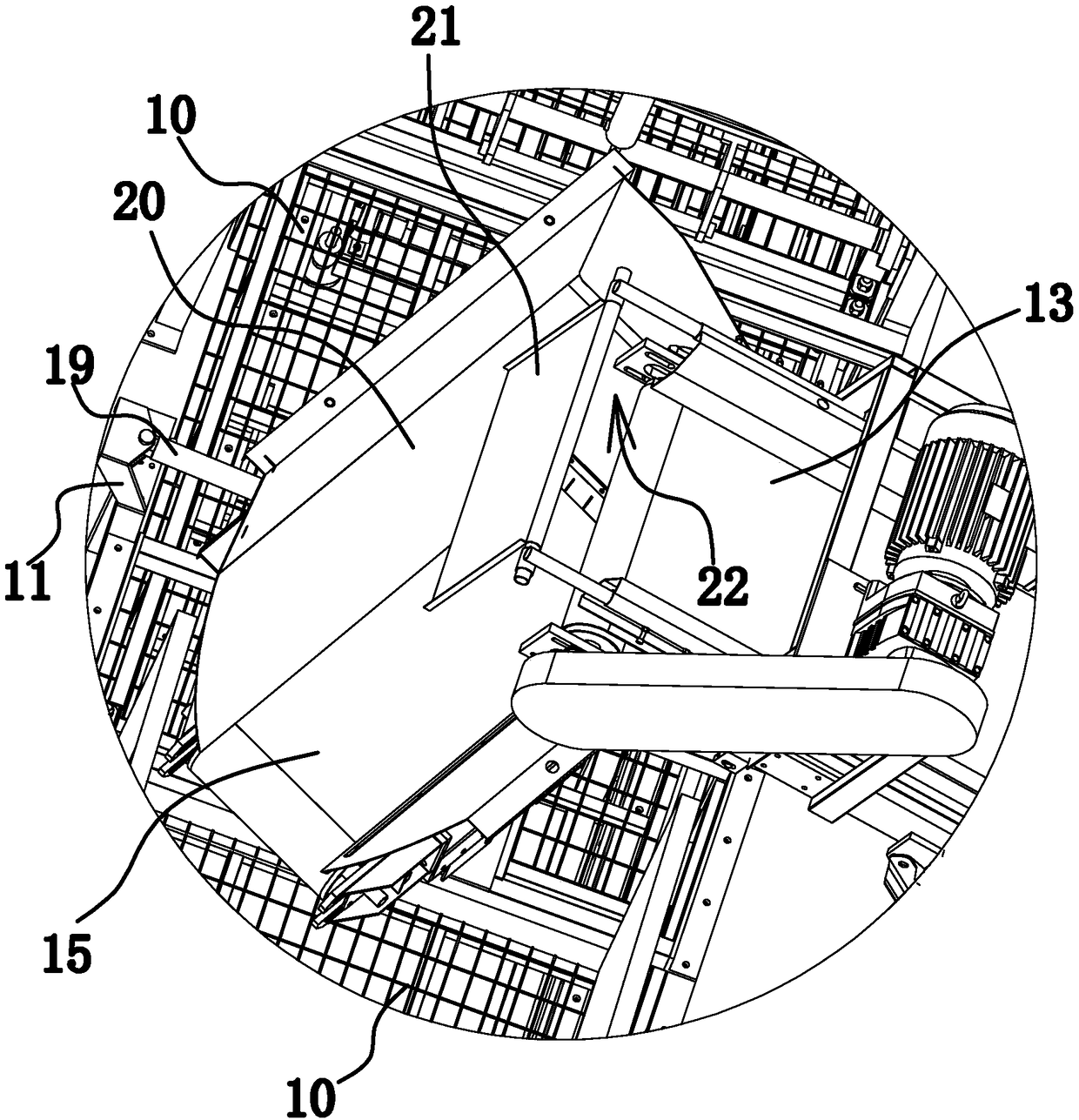

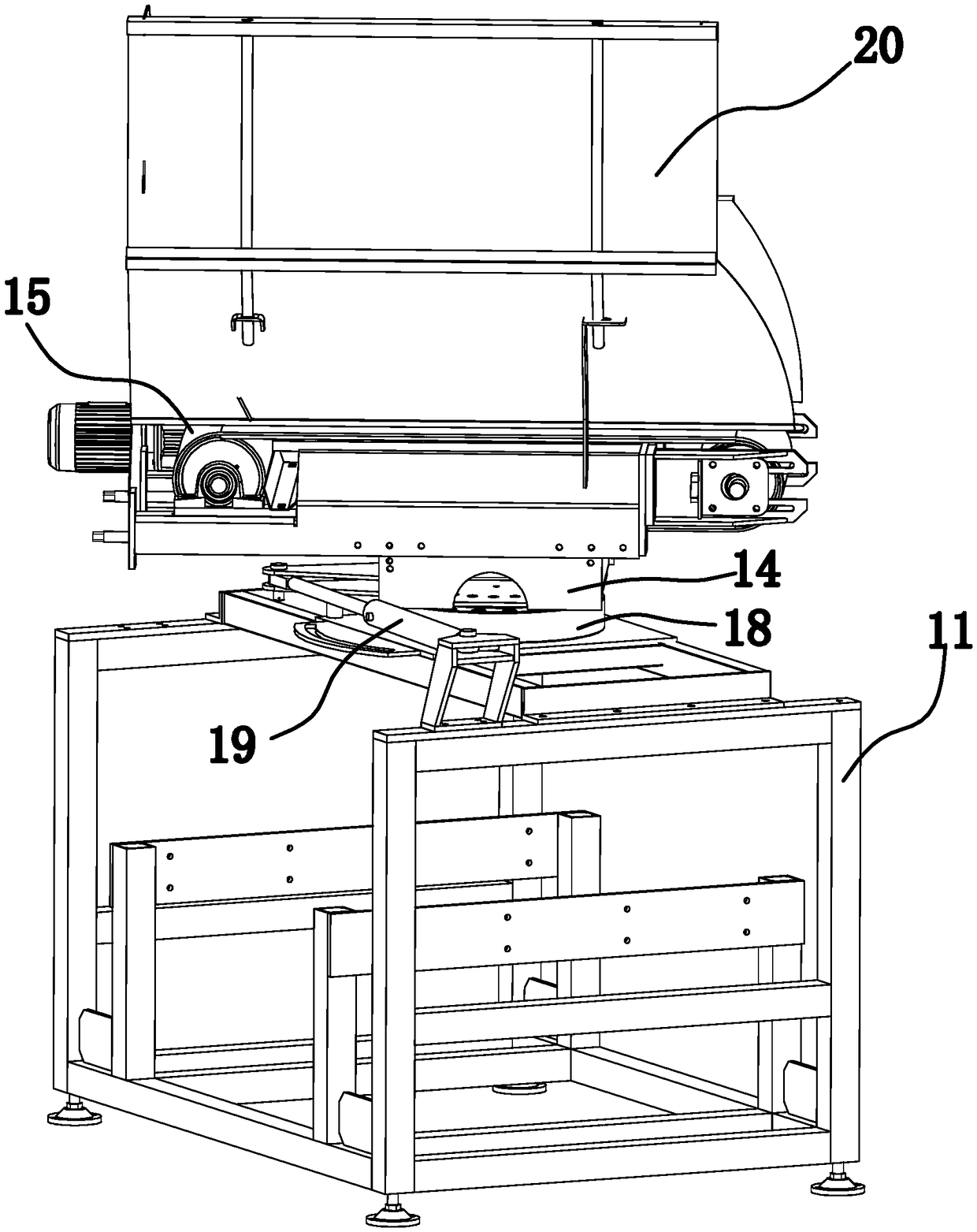

[0026] Such as Figure 1 to Figure 3 As shown, the strain and fertilizer mixing device in the edible mushroom planting equipment includes a mounting frame 11 and a conveying chain 12 horizontally arranged on the mounting frame 11 . One side of the installation frame 11 is obliquely provided with a conveyor belt 13 , and in this embodiment, preferably, the conveyor belt 13 is arranged obliquely upward. A support frame 14 is fixed between the first conveyor belt 13 and the conveyor chain 12, and a second conveyor belt 15 is horizontally arranged on the support frame 14, and the second conveyor belt 15 is directly below the discharge end of the first conveyor belt 13. Wherein, the structure and installation method of conveyor belt one 13, conveyor belt two 15 and conveyor chain 12 are all existing common technologies, and are not described in detail here. Preferred conveyor chain 12 adopts a large roller conveyor chain.

[0027] Such as figure 1 , Figure 4 and Figure 5 As s...

Embodiment 2

[0034] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the swing mechanism includes a motor two and a vertically arranged installation shaft, the lower end of the installation shaft is fixedly connected with the installation frame 11 in the axial direction, and the installation shaft The upper end is fixedly connected with the support frame 14, and the second motor can drive the rotation of the installation shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com