A self-learning based tail tracking method for reversing roughing mill

A self-learning, roughing mill technology, used in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of difficult tail tracking, large spacing, entry speed deviation, etc., to reduce daily maintenance work and system reliability. High, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

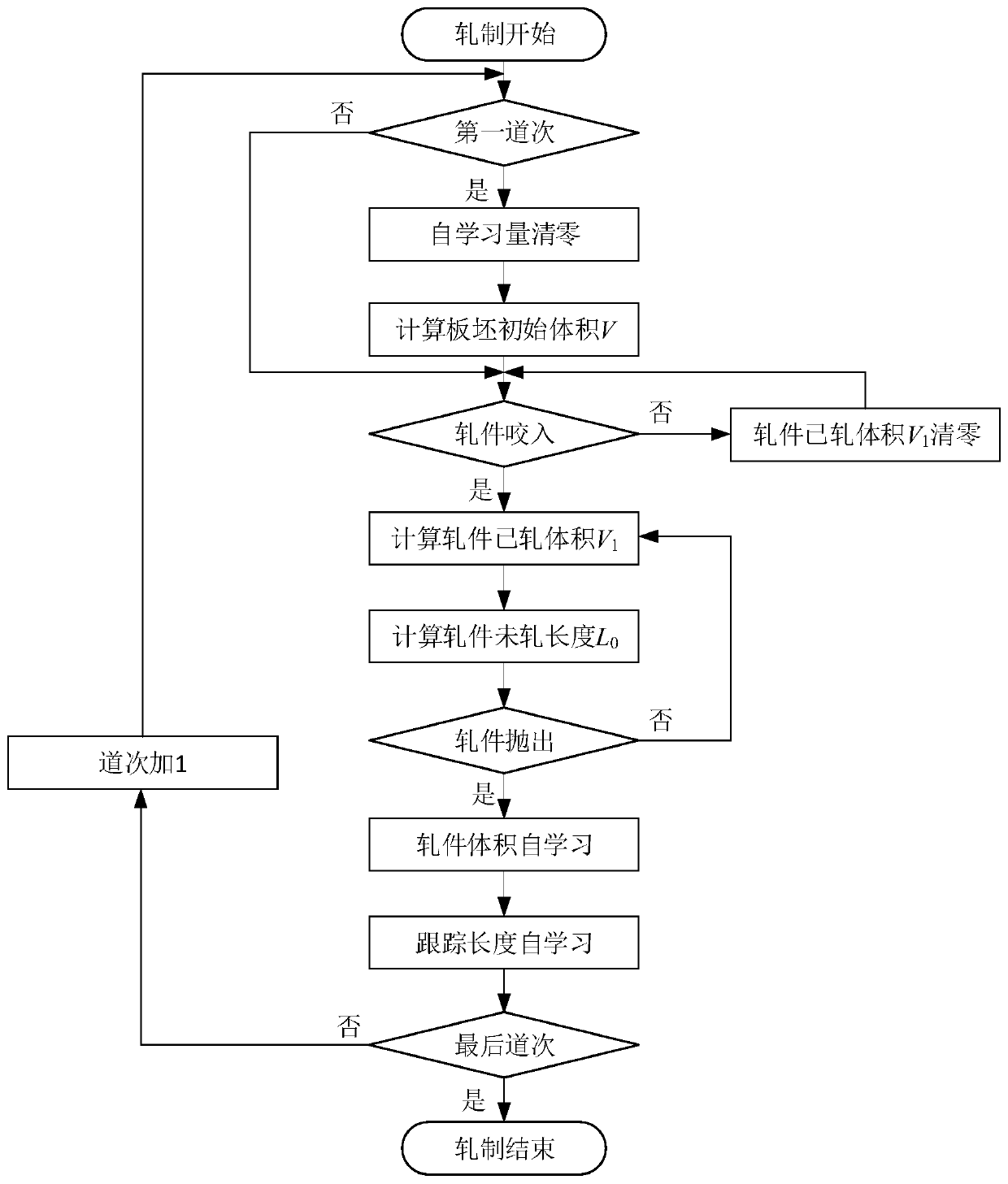

[0046] A self-learning-based reversible roughing mill rolling stock tail tracking method, the specific implementation steps are as follows:

[0047] Step 1: In the first pass, the thickness H, width W, and length L of the incoming slab are used to calculate the total volume V of the rolled piece:

[0048] V=HWL

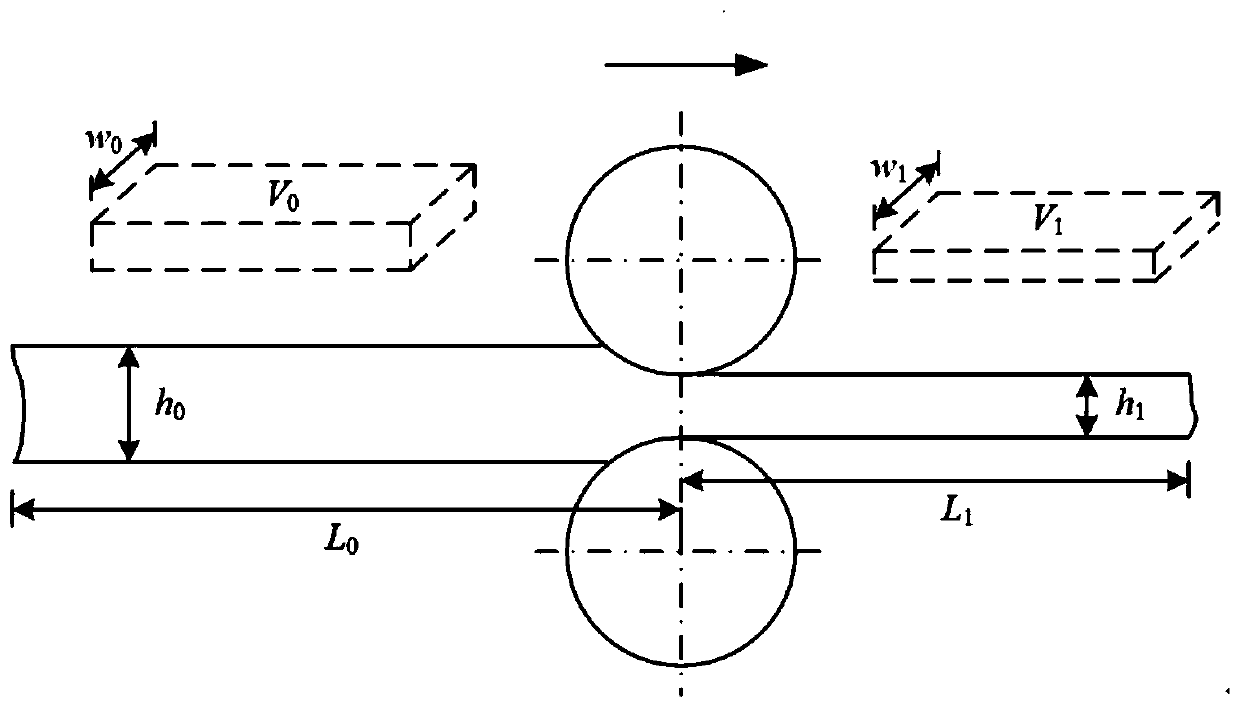

[0049] Step 2: During each pass of rolling, according to the thickness h of the exit of the rolling mill 1 , outlet width w 1 , mill speed v, forward slip value f, calculated rolling volume V 1 :

[0050] V 1 =∫w 1 h 1 v(1+f)dt

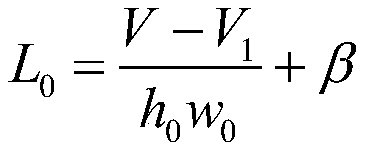

[0051] Step 3: According to the total volume V of the rolled piece, the rolled volume V 1 , to calculate the unrolled volume V 0 , and then according to the mill entrance thickness h 0 , the entrance width w 0 , to calculate the tail tracking length L of the rolled piece 0 :

[0052]

[0053] Among them, β is the tail tracking self-learning correction amount.

[0054] Step 4: At the end of each rolling pass, the volume of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com