Clamp for sawing motor swash plate and production line

A swash plate and sawing technology, which is applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of serious consumption of raw materials and difficulty in meeting design requirements, and achieve the effects of simple structure, high sawing precision, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

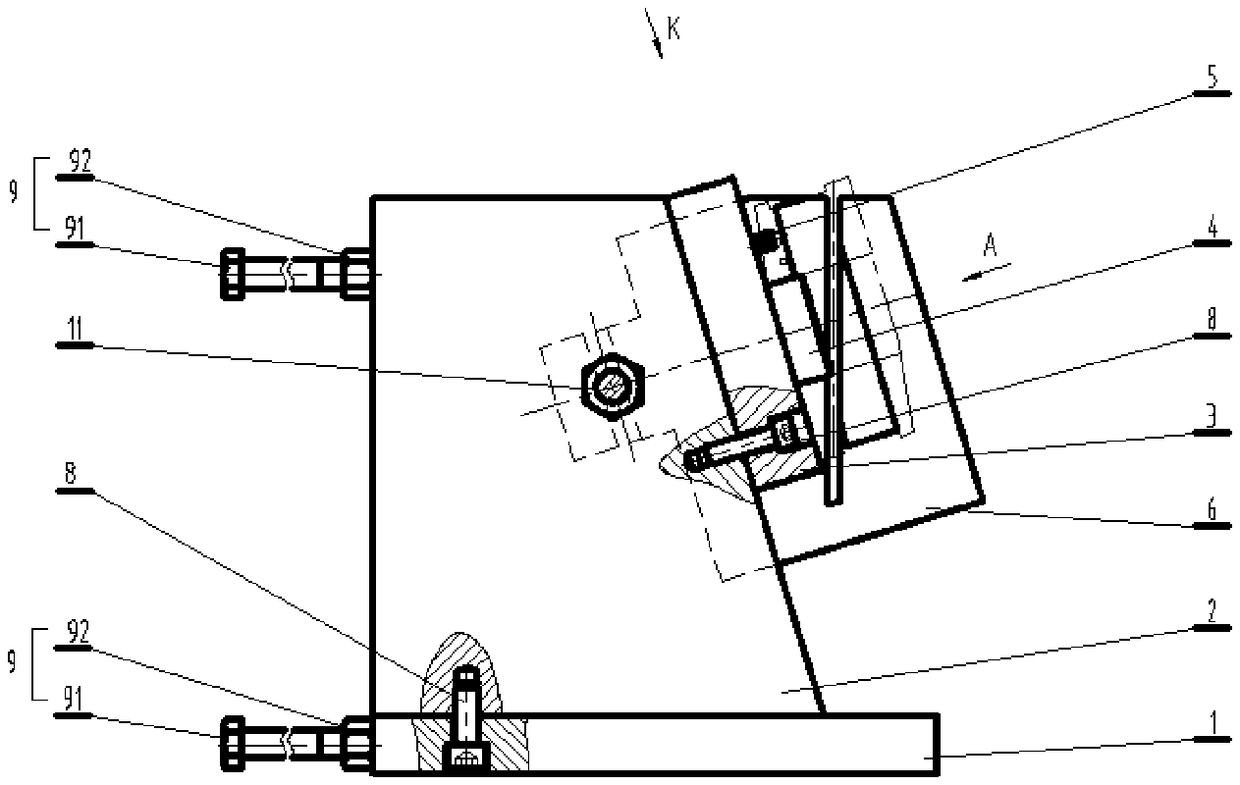

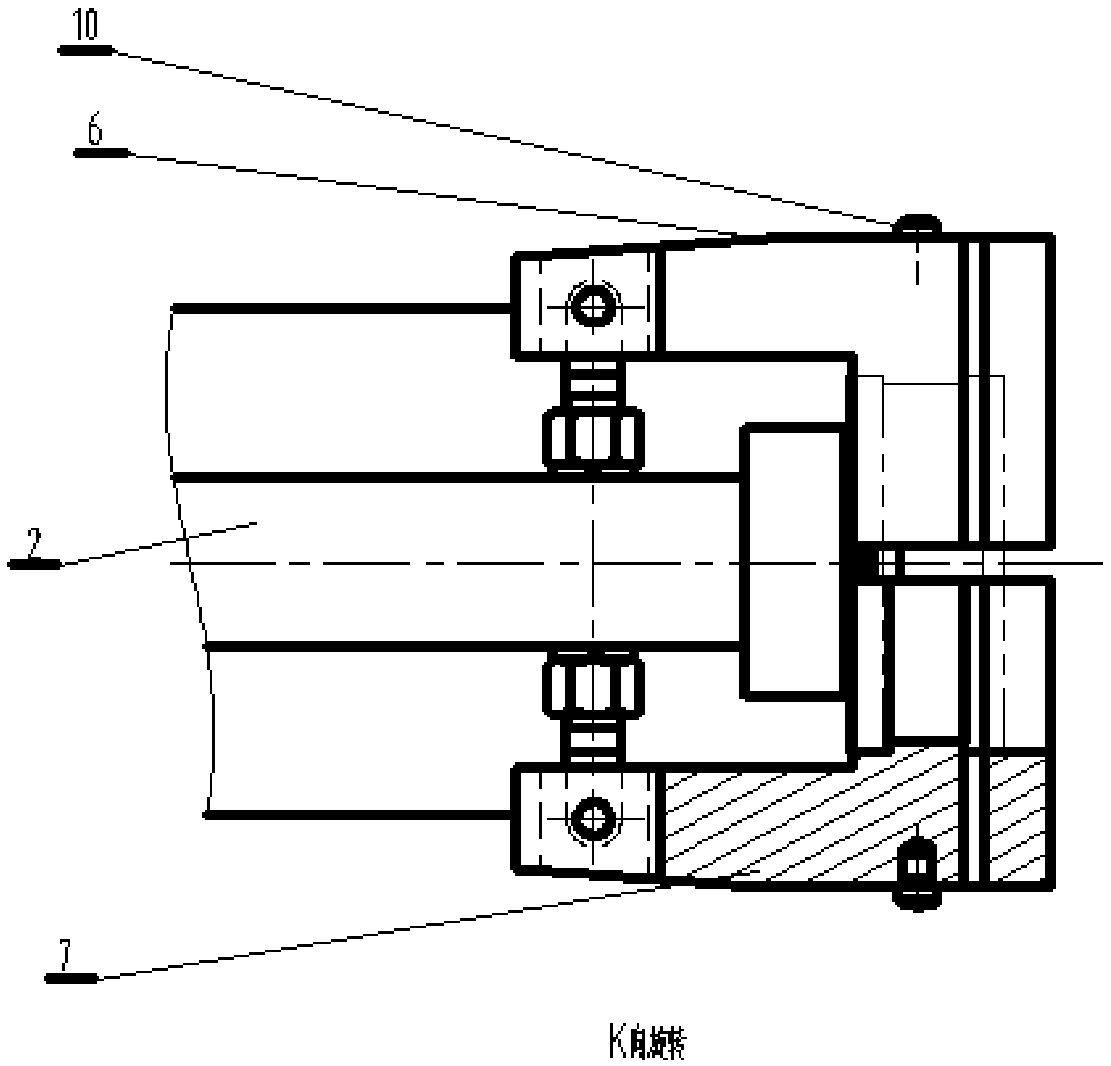

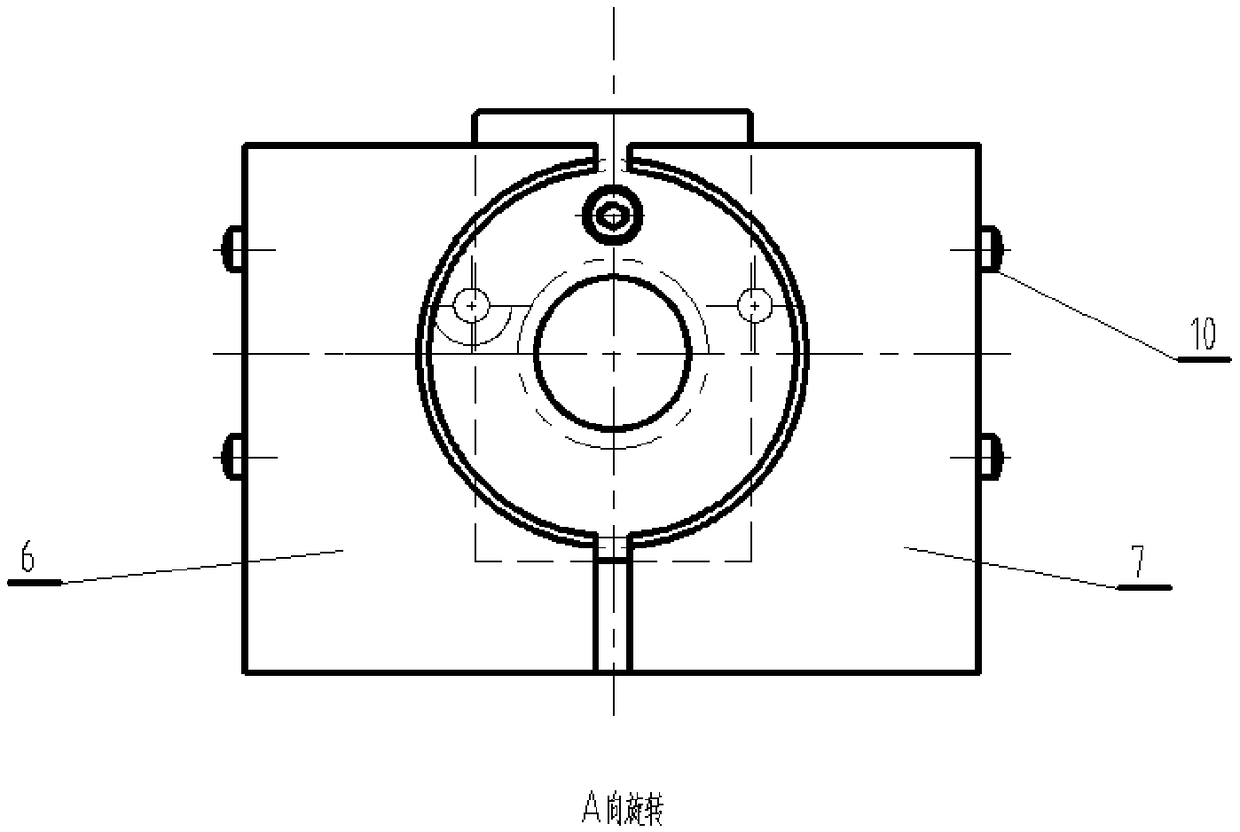

[0028] figure 1 Schematic diagram of the structure of the jig for motor swash plate sawing provided in Embodiment 1 of the present invention; figure 2 Yes figure 1 Middle K direction view; image 3 Yes figure 1 Middle A view; such as Figure 1-Figure 3 As shown, the jig for motor swash plate sawing provided by Embodiment 1 of the present invention includes a base plate 1, a stand plate 2 and a positioning plate 3;

[0029] The stand plate 2 is installed on the base plate 1, the positioning plate 3 is installed on the stand plate 2, the positioning pin 4 and the orientation pin 5 are respectively installed on the positioning plate 3, the positioning pin 4 and the The directional pin 5 is used to determine the center position of the cylindrical part and prevent its circumferential movement. A left clamping block 6 and a right clamping block 7 are respectively hinged on the standing plate 2 on both sides of the positioning plate 3 .

[0030] The jig for motor swash plate sa...

Embodiment 2

[0034] The jig for motor slanting disk sawing provided in the second embodiment is a further improvement on the jig for motor slanting disk sawing provided in the first embodiment. In the first embodiment and Figure 1-Figure 3 On the basis of the motor swash plate sawing jig provided in the second embodiment, it includes a bottom plate 1, a stand plate 2 and a positioning plate 3;

[0035] The stand plate 2 is installed on the base plate 1, the positioning plate 3 is installed on the stand plate 2, the positioning pin 4 and the orientation pin 5 are respectively installed on the positioning plate 3, the positioning pin 4 and the The directional pin 5 is used to determine the center position of the cylindrical part and prevent its circumferential movement. A left clamping block 6 and a right clamping block 7 are respectively hinged on the standing plate 2 on both sides of the positioning plate 3 .

[0036] The jig for motor swash plate sawing provided by the present invention ...

Embodiment 3

[0041] The jig for motor slanting disk sawing provided in the third part of this embodiment is a further improvement on the jig for motor slanting disk sawing provided in the first embodiment. In the first embodiment and Figure 1-Figure 3 On the basis of the motor swash plate sawing jig provided in the third embodiment, it includes a base plate 1, a stand plate 2 and a positioning plate 3;

[0042] The stand plate 2 is installed on the base plate 1, the positioning plate 3 is installed on the stand plate 2, the positioning pin 4 and the orientation pin 5 are respectively installed on the positioning plate 3, the positioning pin 4 and the The directional pin 5 is used to determine the center position of the cylindrical part and prevent its circumferential movement. A left clamping block 6 and a right clamping block 7 are respectively hinged on the standing plate 2 on both sides of the positioning plate 3 .

[0043] The jig for motor swash plate sawing provided by the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com