Automatic turnover device

A technology of automatic flipping and flipping of frames, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as unfavorable continuous operation structure optimization of automatic production lines, inability to adapt to product size production applications, insufficient applicability, etc. Good promotion and application value, simple structure, significant progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

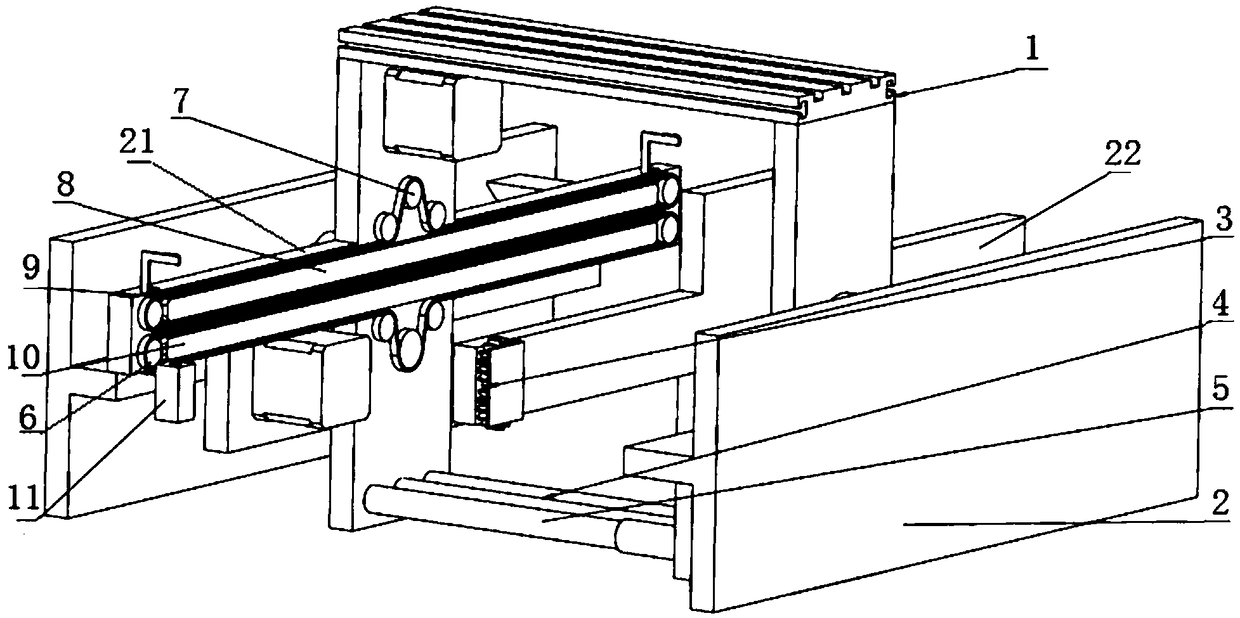

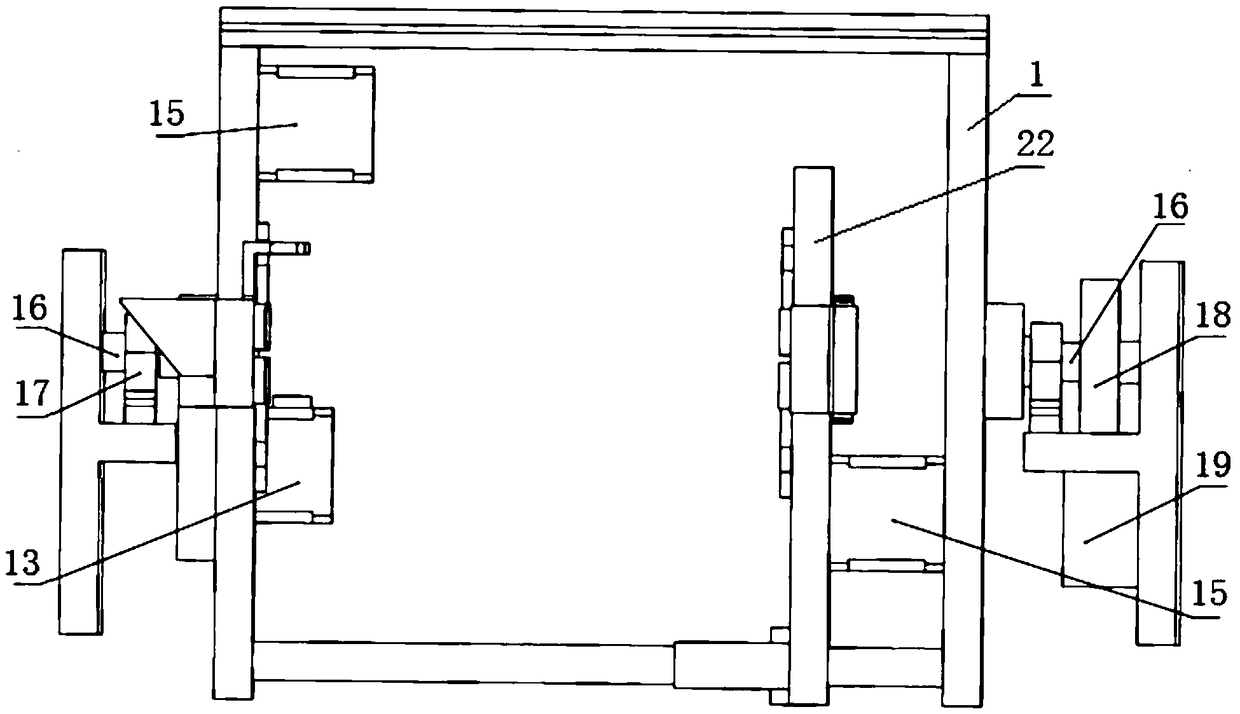

[0025] combine Figure 1 to Figure 5 As shown, an automatic turning device provided in this embodiment includes a worktable, a turning frame 1, a transmission mechanism, a turning mechanism and a positioning mechanism. Plate 2, the outer panel 2 of the workbench has a horizontal horizontal plate and a vertical side plate, and the horizontal horizontal plates of the two outer panels of the workbench 2 are arranged oppositely; The two side plates of the overturning frame body 1 are vertical transmission mechanism support horizontal plate one 21 and transmission mechanism support horizontal plate two 22; the transmission mechanism support horizontal plate one 21 and the transmission mechanism support horizontal plate two 22 are respectively fixed on On the flipping frame body 1, the outer center positions of the two side panels of the flipping frame body 1 are reversibly connected with the two outer panels 2 of the workbench respectively through the flipping mechanism; For the c...

Embodiment 2

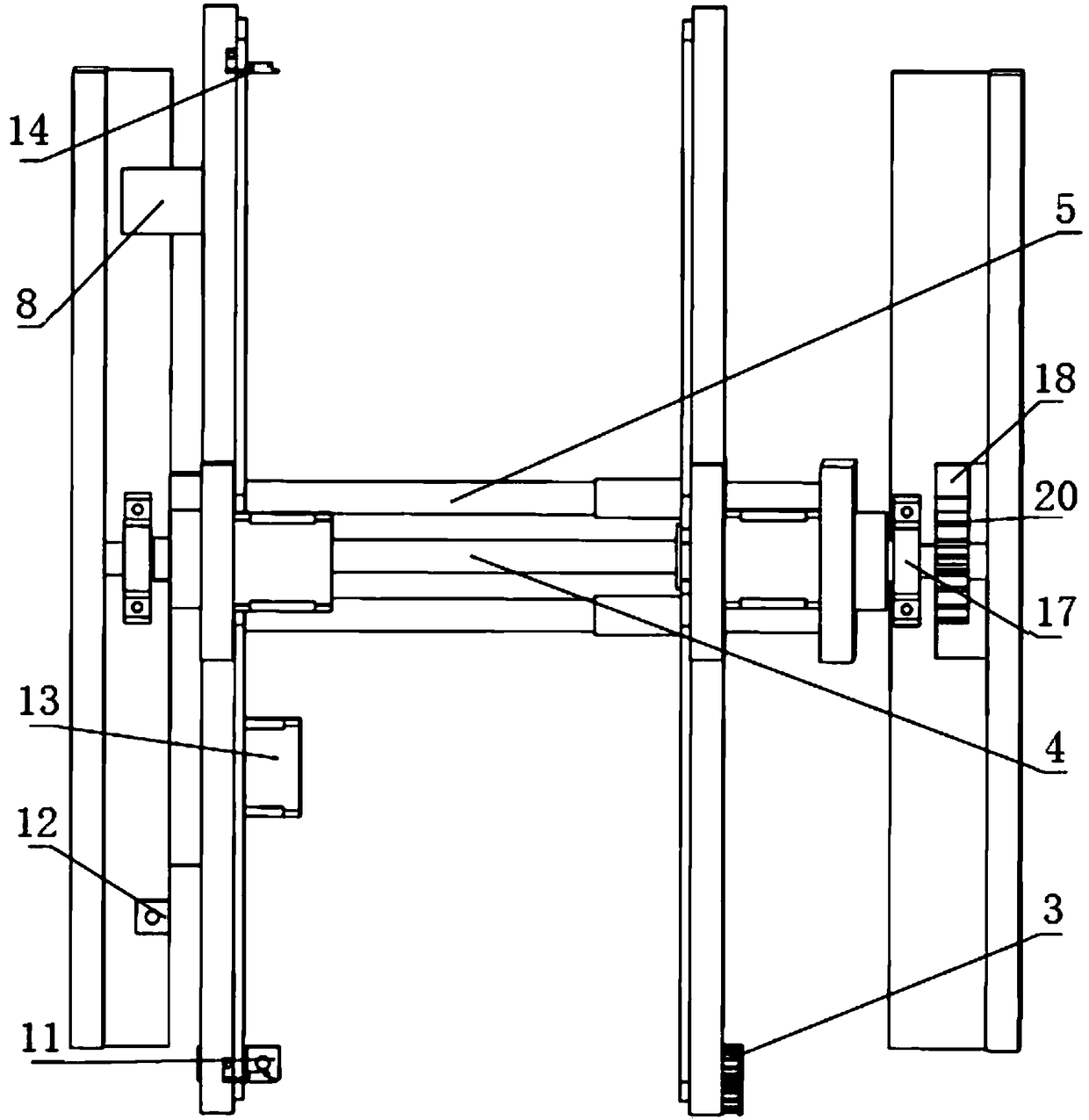

[0032] The automatic turning device provided by this embodiment is only different from that of Embodiment 1 in that: the bottom of the turning frame 1 includes two guide posts 5 and a screw 4, and the second horizontal plate 22 of the transmission mechanism support It is a cross-shaped structural plate, and the two ends of the two guide posts 5 are respectively fixedly connected to the bottom of the side plate on the side of the flip frame 1 away from the cross-shaped structural plate and the bottom of the cross-shaped structural plate. , the guide post 5 is a telescopic structure, the screw 4 is arranged between the two guide posts 5, and one end of the screw 4 is connected with the turning frame 1 away from the cross-shaped structural plate through a bearing. The bottom of the side plate on the side is rotatably connected, and the other end passes through the bottom of the cross-shaped structural plate and is screwed to it, and the screw rod 4 is driven and connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com