Backing plate for subway track

A pad and track technology, applied in the field of railway track systems, can solve the problems of poor mechanical strength, poor shock absorption and noise reduction, large compression deformation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

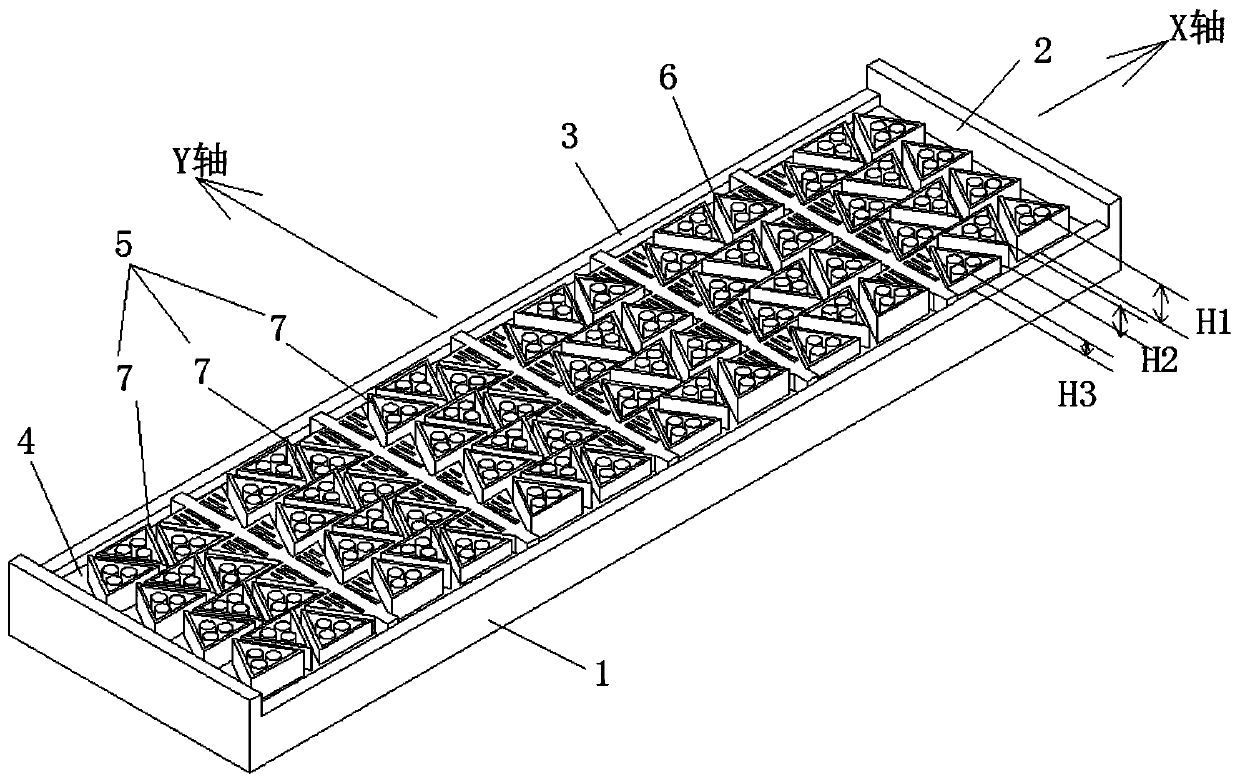

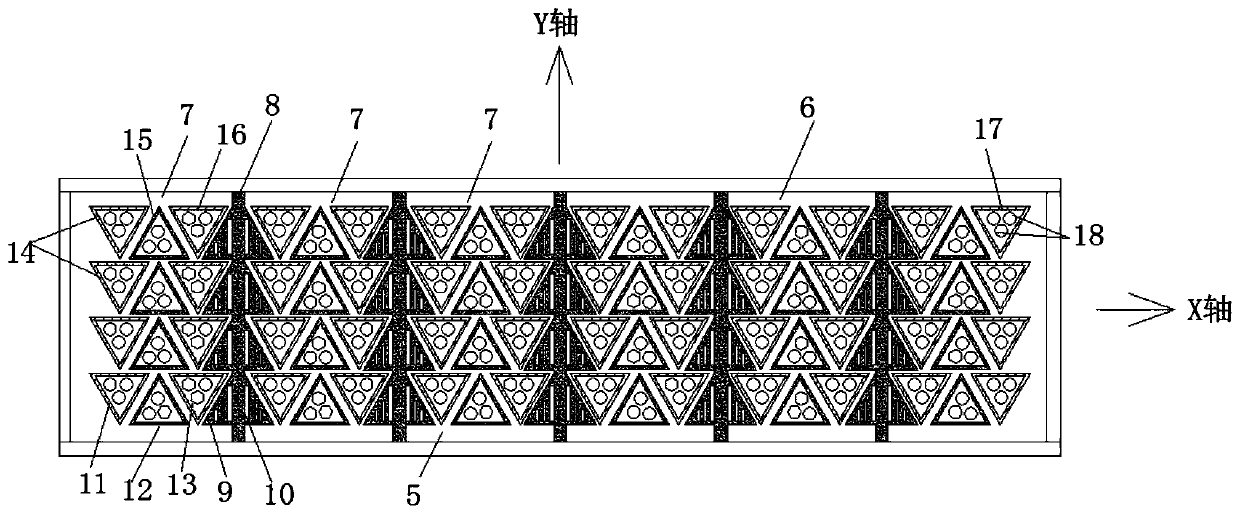

[0034] A backing plate for a subway track, comprising a backing plate body 1; the backing plate body 1 is made of rubber material and integrally formed by injection molding;

[0035] The backing plate body 1 is a cube structure, and the left and right sides of the upper end surface of the backing plate body 1 are provided with retaining strips 2, and the retaining strips 2 are vertically connected with the backing plate body 1 to form a whole;

[0036] The backing plate body 1 is provided with seals 3 on the front and rear sides of the upper end, and the seals 3 are connected with the retaining strips 2 to form a whole; the two retaining strips 2 are connected with the two seals 3 to form an upper accommodation chamber 4;

[0037] The upper chamber 4 includes a first energy-absorbing area 5 and a second energy-absorbing area 6. The first energy-absorbing area 5 and the second energy-absorbing area 6 are symmetrical about the Y axis; Parallel, the X-axis passes through the geom...

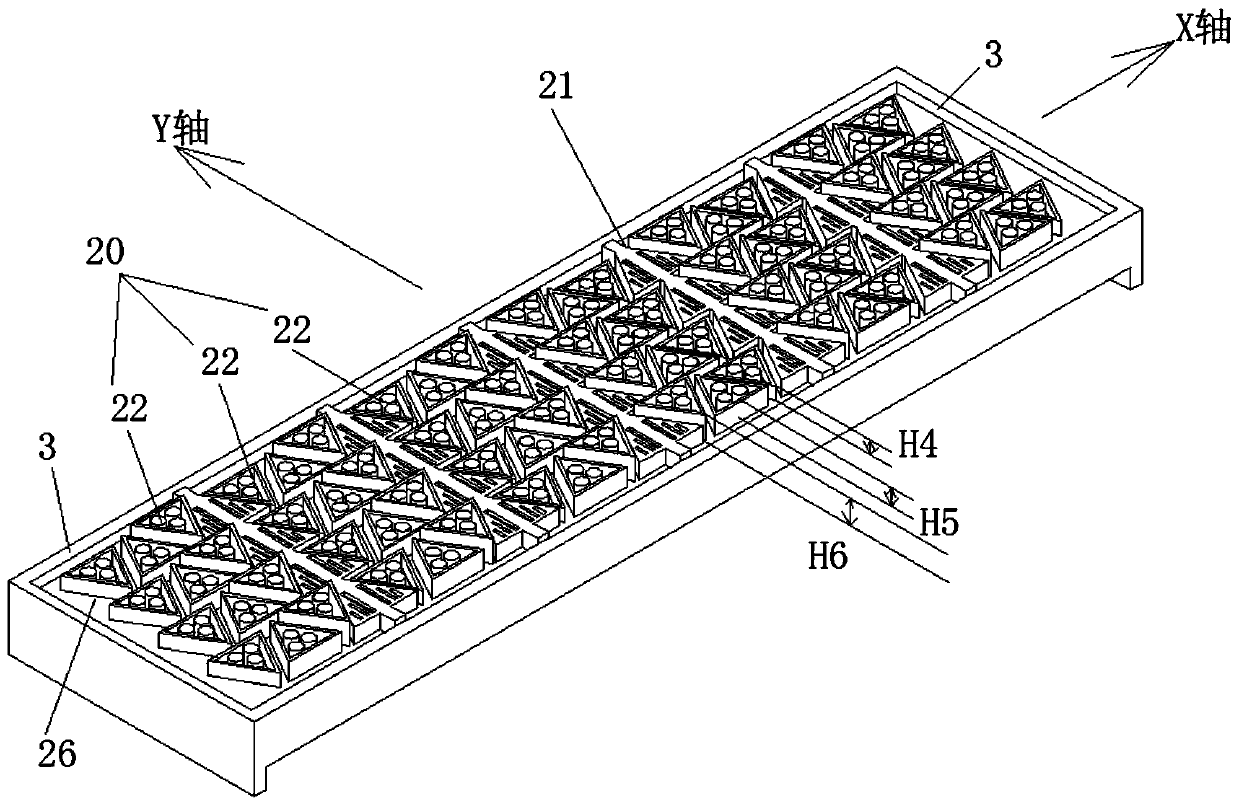

Embodiment 2

[0053] It is basically the same as Example 1, the difference is:

[0054] The second secondary energy-absorbing column 30 includes a plurality of second secondary energy-absorbing units 28, and the second secondary energy-absorbing units 28 are evenly distributed along the Y direction. The second secondary energy-absorbing units 28 are different from the first secondary energy-absorbing units 27 except for their heights. Others are the same (including structure, size).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com