Large-diameter ultra-deep high-pressure jet grouting construction method

A construction method, a technology of high-pressure injection, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of poor mud discharge, large suction port, blockage, etc., and achieve the effect of ensuring quality and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

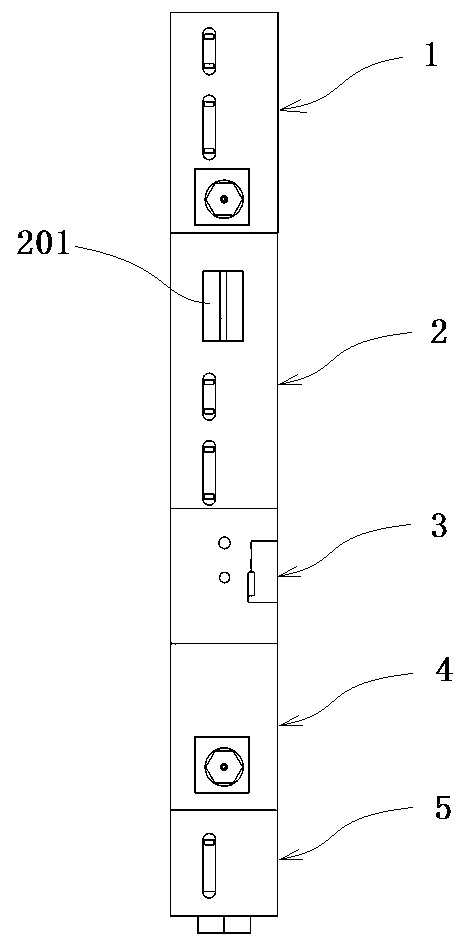

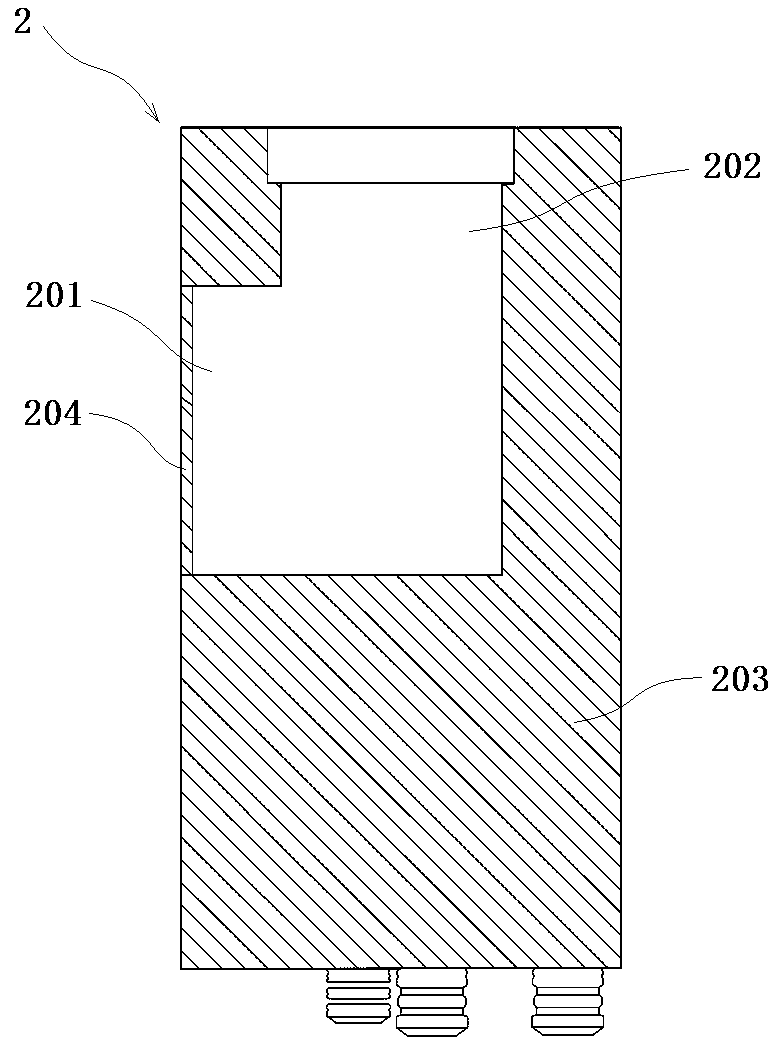

[0032] Embodiment 1: as Figure 1-9 As shown, this embodiment specifically relates to a large-diameter ultra-deep high-pressure jet grouting construction method. The construction method mainly uses the water-cutting section 1 provided at the lower end of the drilling tool 9 to water-cut the soil and utilize the slurry-returning section 2 Carry out vacuum pumping for the mud, and at the same time, use the cement slurry nozzle 403 installed horizontally on the spraying section 4 to rotate and spray the cement slurry to the periphery of the drilling tool 9 to form a rotary spraying pile body 16, which can effectively control the pressure in the ground while achieving efficient mud discharge , so as to ensure the quality of the shotcrete pile.

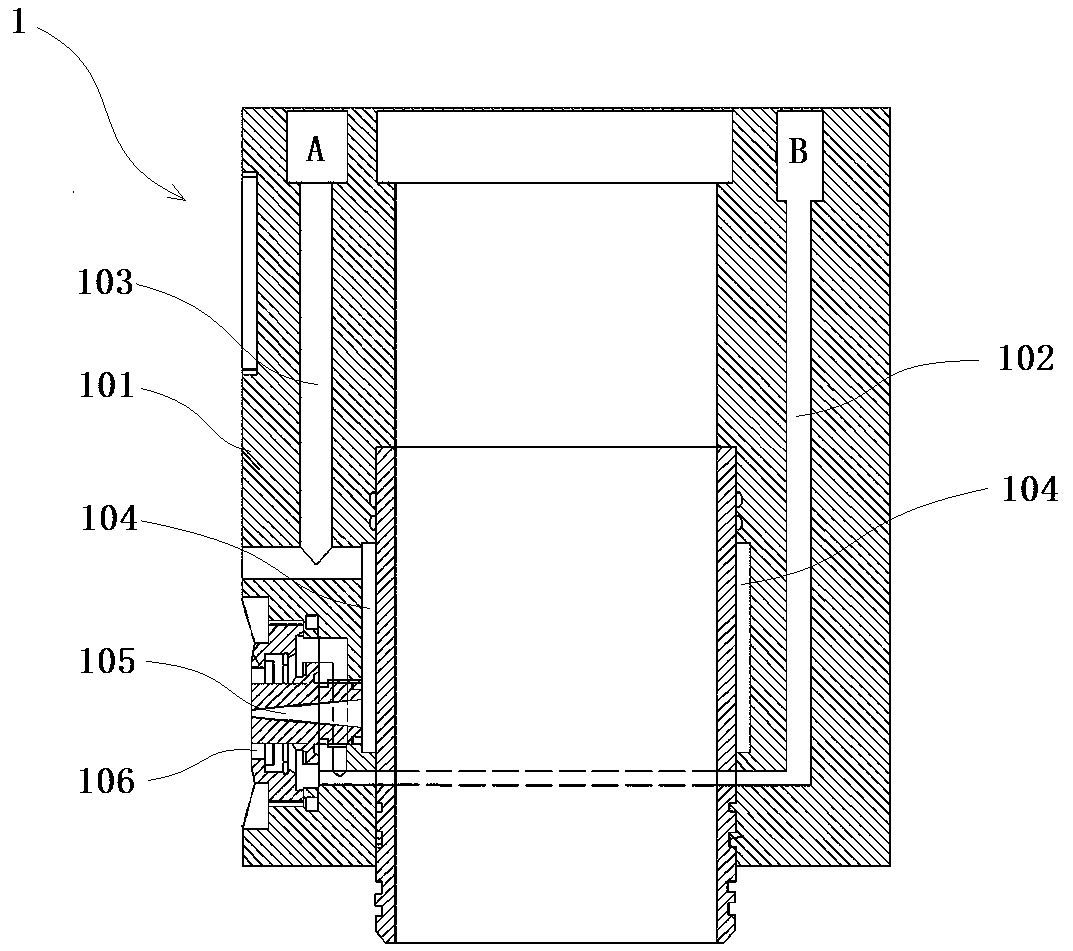

[0033] Such as figure 1 , 2 As shown, the water cutting section 1 includes a cylindrical water cutting section body 101, at least one cutting nozzle 105 is horizontally arranged on the outer wall surface of the water cutting section body...

Embodiment 2

[0046] Embodiment 2: as Figure 10 , 11 , 13, the difference between this embodiment and embodiment 1 is that in this embodiment, the cutting nozzle 105 is arranged inclined downwards, while the cement slurry nozzle 403 is arranged inclined upward, the two are on the same vertical line, and the two spray The emerging cutting water 15 and cement slurry 13 meet on the injection surface 18, and by adjusting the inclined setting angles of the cutting nozzle 105 and the cement slurry nozzle 403 respectively, the position of the injection surface 18 at the intersection can be controlled, that is, they meet at the set diameter position , so that a jet grouting pile body 16 with a designed diameter is formed around the drilling tool 9 .

[0047] In practical application, according to the design diameter of the jet grouting pile body 16 that needs to be applied, adjust the distance between the cutting nozzle 105 and the cement slurry nozzle 403 on the drilling tool 9 and the respectiv...

Embodiment 3

[0050] Example 3, such as Figure 12 As shown, the difference between this embodiment and Embodiment 2 is that in this embodiment, a horizontally arranged cutting nozzle 105 is added to the water cutting section 1, and the horizontally arranged cutting nozzle 105 can improve the soil around the drilling tool 9. For powerful cutting, while the diameter of the jet grouting pile body can be effectively controlled according to the construction requirements, it can also ensure that the diameter of the jet grouting pile body 16 is sufficiently large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com