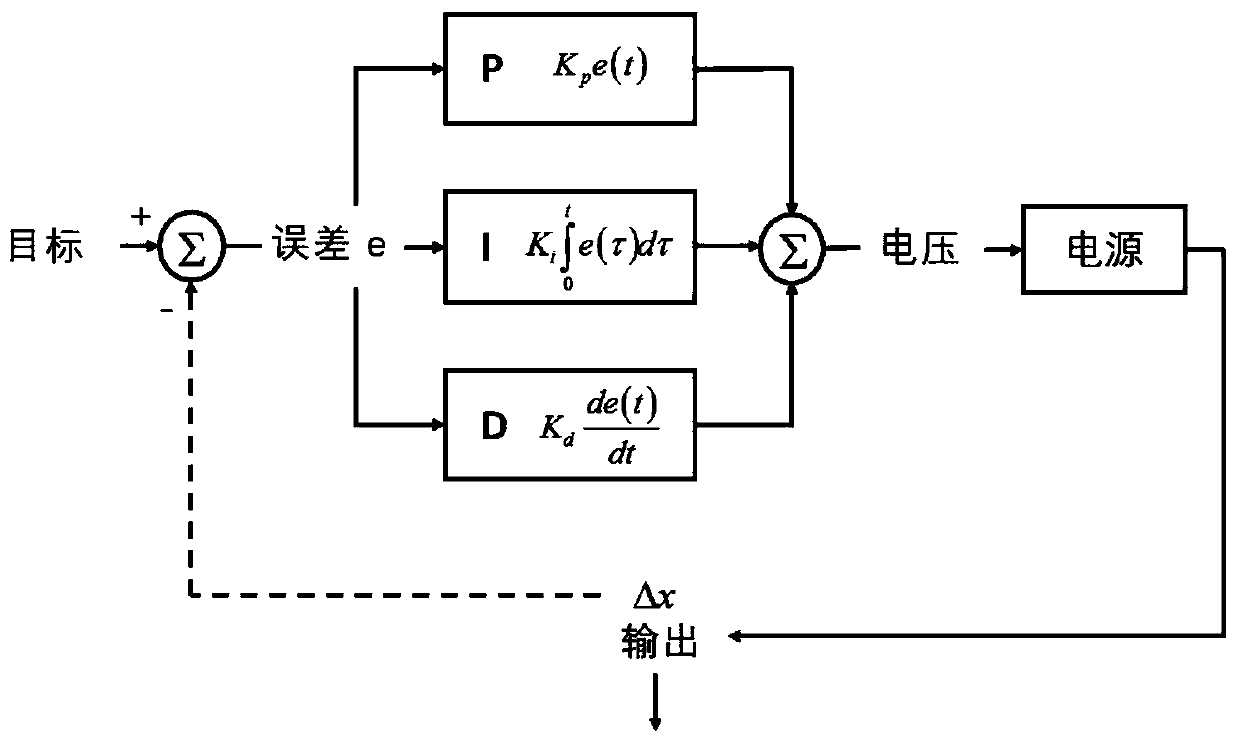

A shape memory alloy intelligent shock absorber based on pid control

A technology of intelligent shock absorption and memory alloy, which is applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve the problems of small recoverable displacement and poor controllability, and achieve fast recovery of balance, reduce amplitude, increase The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Such as Figure 4 ~ Figure 12As shown, a shape memory alloy intelligent damping support based on PID control includes a base 1, a common spring 3, a push-pull rod A4, a support member 5, a push-pull rod B6, a push-pull rod C7, an outer shape memory alloy spring A8, an outer Shape memory alloy spring B9, outer shape memory alloy spring C10, inner shape memory alloy spring A12, inner shape memory alloy spring B13, inner shape memory alloy spring C11, slider A14, slider B15, slider C16, power supply and PID control System 17, guide rail A19, guide rail B20, guide rail C18 and central shaft 21; wherein, the base 1 is a circular groove structure, and the central shaft 21 is vertically fixed at the top center of the base 1, and the central shaft 21 The guide rail A19, guide rail B20 and guide rail C18 in the horizontal direction are arranged equidistantly along the circumferential direction between the bottom and the side wall of the base 1, and the guide rail A19, guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com