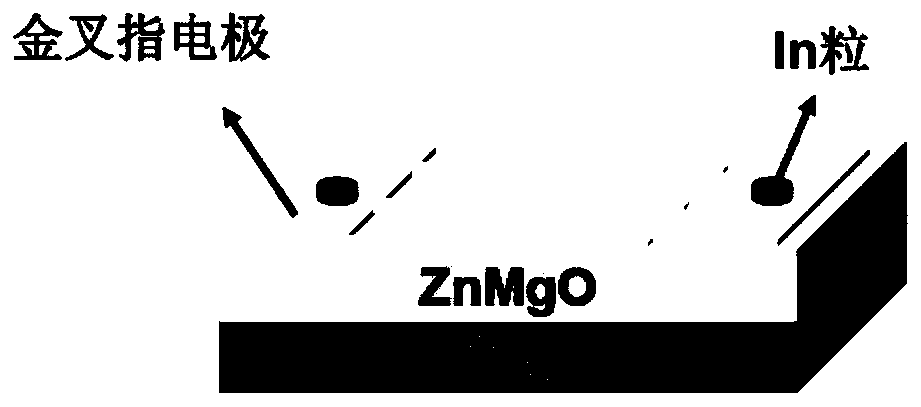

A znmgo UV detector

A technology of ultraviolet detectors and thin film layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems affecting the crystal quality of the thin film and the comprehensive performance of the device, and achieve easy control of the reaction process, steep absorption cut-off edge, and crystal quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1.1 Use trichlorethylene, acetone, and ethanol to clean the sapphire substrate respectively, and then dry it with dry nitrogen. (The thickness of the substrate is 0.45~0.55mm, the size is 2 inches, and the square is about 5-10mm×5-10mm after cutting)

[0058] 1.2 Put the sapphire substrate in 1.1 into the MOCVD growth equipment, adjust the growth temperature to 450°C, and the vacuum degree of the growth chamber to 1×10 4 Pa, using diethylzinc as the zinc source, dimethylmagnesium as the magnesium source, the molar concentration ratio of zinc and magnesium is adjusted by using different high-purity nitrogen carrier gas ratios, and the oxygen flow rate is 150mL / min. The carrier gas flow rate of the zinc-based pipeline was 15mL / min, and the carrier gas flow rate of the dimethylmagnesium pipeline was 50mL / min.

[0059] 1.3 After growing for 2 hours, turn off the organic source, lower the temperature at a cooling rate of 5°C / min, and finally lower it to room temperature, ta...

Embodiment 2

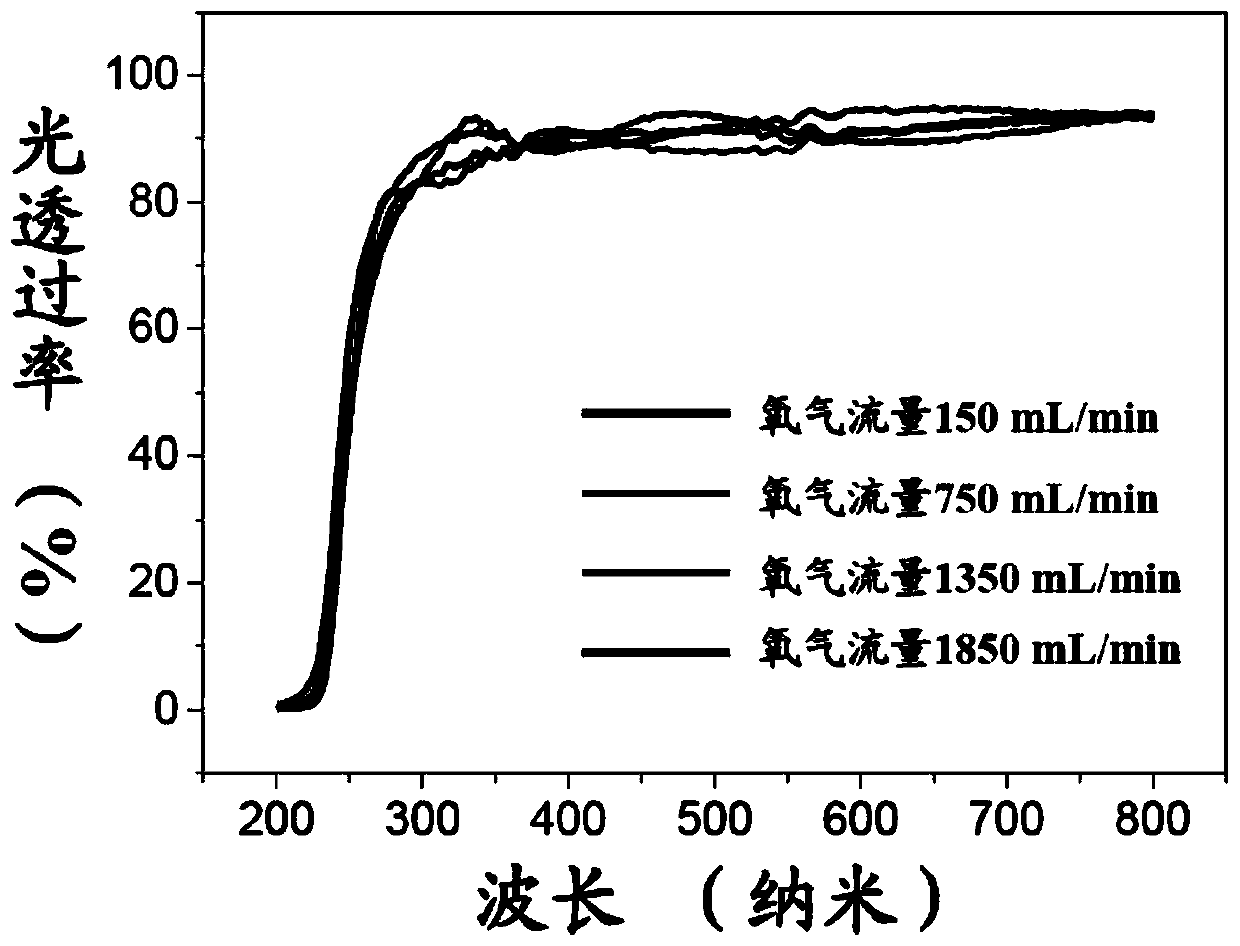

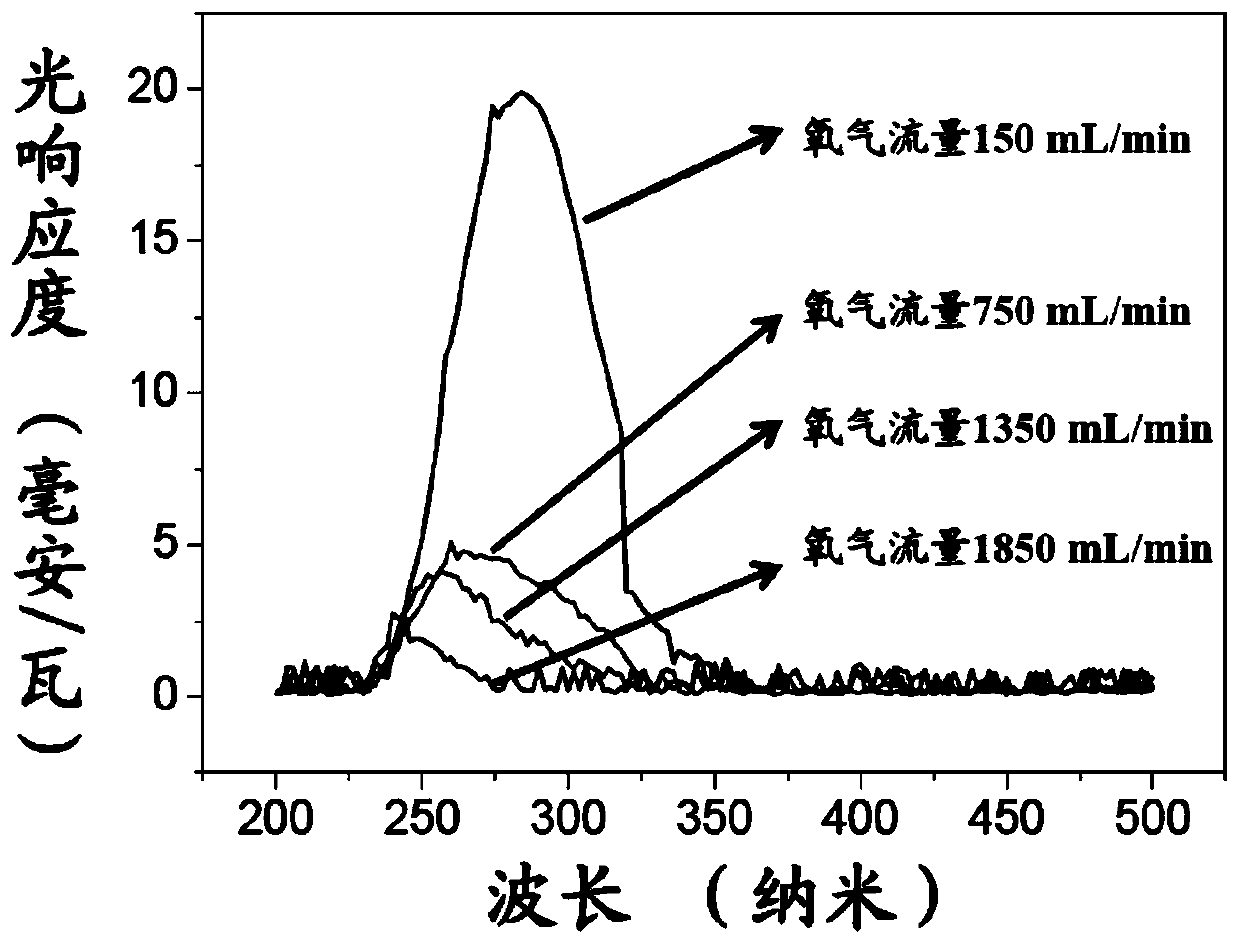

[0065] In order to test the influence of the flow rate of oxygen on the device preparation, only the flow rate of oxygen was changed, and other conditions were the same as in Example 1, and a series of ultraviolet light detection devices were obtained. Oxygen flow rate is 750mL / min, 1350mL / min, 1850mL / min.

[0066] figure 2 It is the ultraviolet-visible light absorption spectrum of the ZnMgO thin film layer. It can be seen from the figure that with the change of the oxygen flow rate, the light absorption cut-off edge of the ZnMgO thin film layer does not change, and is located near 230nm.

[0067] The photoresponse of the ZnMgO ultraviolet detector that obtains in embodiment 2 is detected, obtains its photoresponse spectrum such as image 3 As shown, it can be seen from the figure that the photoresponse cut-off edge of devices prepared under different oxygen flow conditions has changed significantly, from 350nm to around 275nm.

Embodiment 3

[0069] 3.1 Use trichlorethylene, acetone, and ethanol to clean the sapphire substrate respectively, and then dry it with dry nitrogen. (The thickness of the substrate is 0.45~0.55mm, the size is 2 inches, and the square is about 5-10mm×5-10mm after cutting)

[0070] 3.2 Put the sapphire substrate in 3.1 into the MOCVD growth equipment, adjust the growth temperature to 450°C, and the vacuum degree of the growth chamber to 1×10 4 Pa, using diethylzinc as the zinc source, dimethylmagnesium as the magnesium source, the molar concentration ratio of zinc and magnesium is adjusted by using different high-purity nitrogen carrier gas ratios, and the oxygen flow rate is 150mL / min. The carrier gas flow rate of the zinc-based pipeline was 15mL / min, and the carrier gas flow rate of the dimethylmagnesium pipeline was 80mL / min.

[0071] 3.3 After growing for 2 hours, turn off the organic source, lower the temperature at a cooling rate of 5°C / min, and finally lower it to room temperature, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com