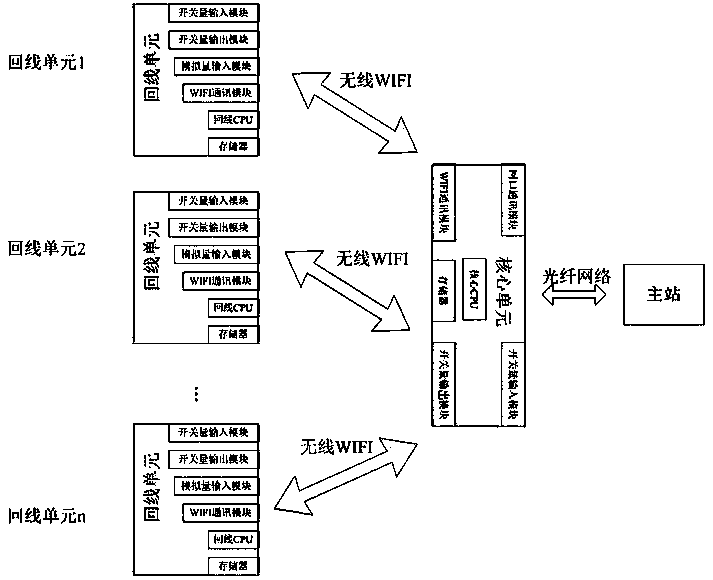

Distributed distribution automation station terminal DTU based on wireless transmission technology

A wireless transmission, automation station technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve the problems of difficult maintenance, difficult to replace lines, complicated DTU wiring, etc., to facilitate maintenance and maintenance, and improve construction. The effect of installation efficiency and reduction of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0014] The implementation method includes the following steps:

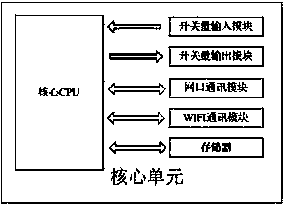

[0015] (1) The core unit is connected to the master station;

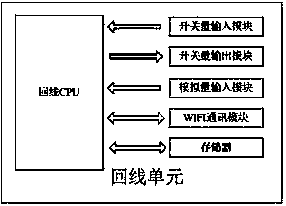

[0016] (2) The loop unit is connected to the core unit;

[0017] (3) The core unit, loop unit acquisition control and data transmission and sharing with the master station.

[0018] The steps (1) connecting the core unit to the master station includes: 1) powering on the core unit to complete the initialization of each module; 2) setting the master station address according to the master station information, and connecting the master station through the optical fiber network; 3) the master station according to DTU For the user information of the device, establish a user profile in the master station.

[0019] The step (2) connecting the loop unit to the core unit includes: 1) power on the loop unit to complete the initialization of each module; 2) wait for the core unit to power on, and set the loop unit parameters according to the core unit WIFI address, Mak...

Embodiment 1

[0028] When implemented, it specifically includes the following steps: A) the core unit is connected to the main station; B) the loop unit is connected to the core unit; C) the core unit, loop unit acquisition control, and data transmission and sharing with the main station;

[0029] A) The core unit is connected to the master station, after the core unit is powered on

[0030] (1) The system is powered on to complete the initialization of each module;

[0031] (2) Set the master station address according to the master station information, and connect to the master station through the optical fiber network;

[0032] (3) The master station establishes user files in the master station according to the user information of the DTU equipment;

[0033] B) The loop unit is connected to the core unit, and the loop unit is powered on first:

[0034] (1) The system is powered on to complete the initialization of each module;

[0035] (2) After waiting for the core unit to be powered on, according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com