Cutting device for steel scrap processing

A technology for cutting devices and scrap steel, which is applied in the direction of sawing machine accessories, sawing machine devices, metal processing equipment, etc., which can solve the problems of low service life of cutting devices, affecting the service life of equipment and processing efficiency, and low intelligence. Equipment cost, good practical value and promotion value, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

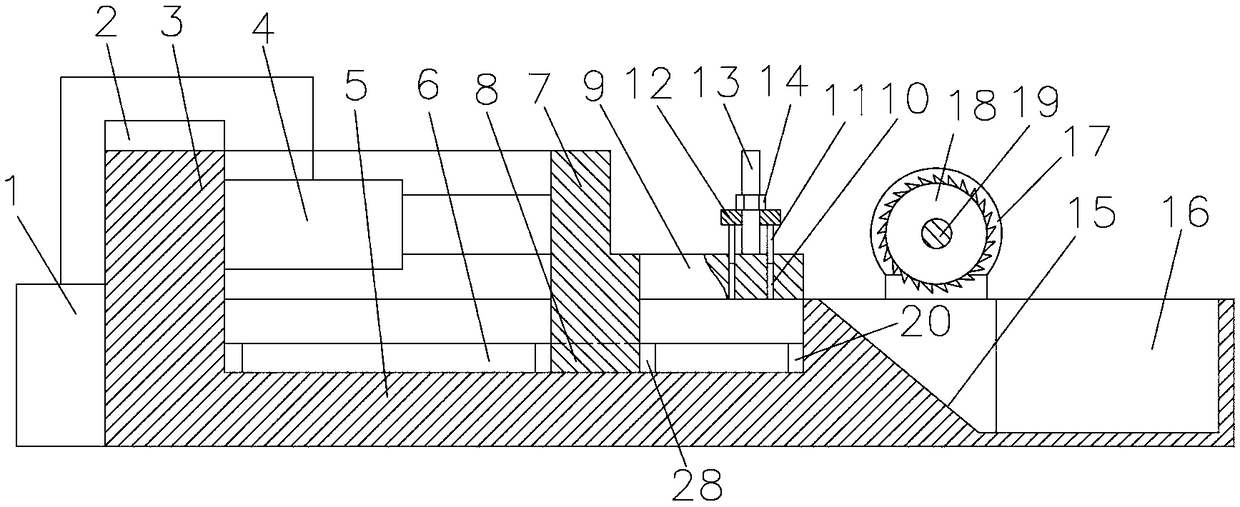

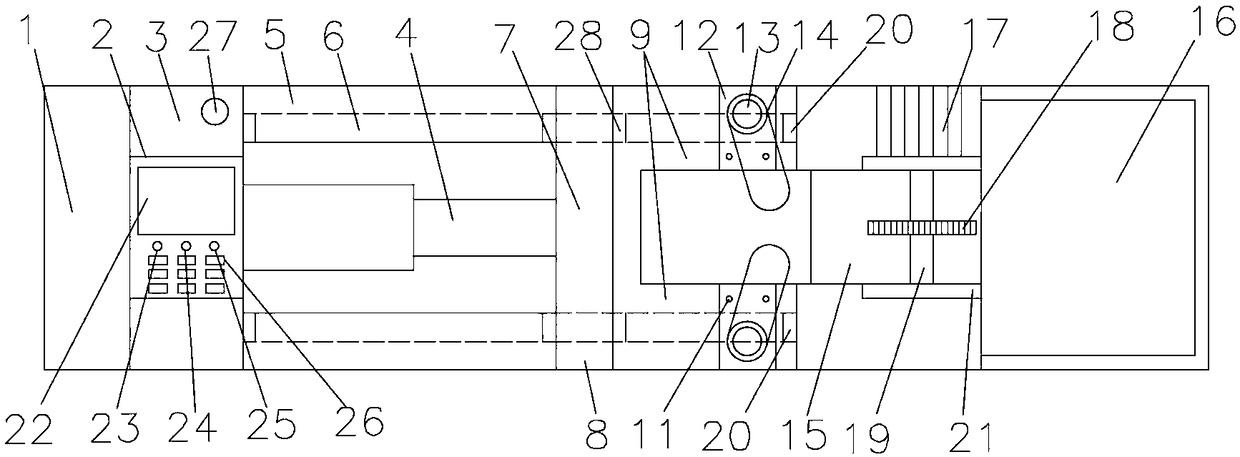

[0028] Example 1, such as Figure 1-3 Shown:

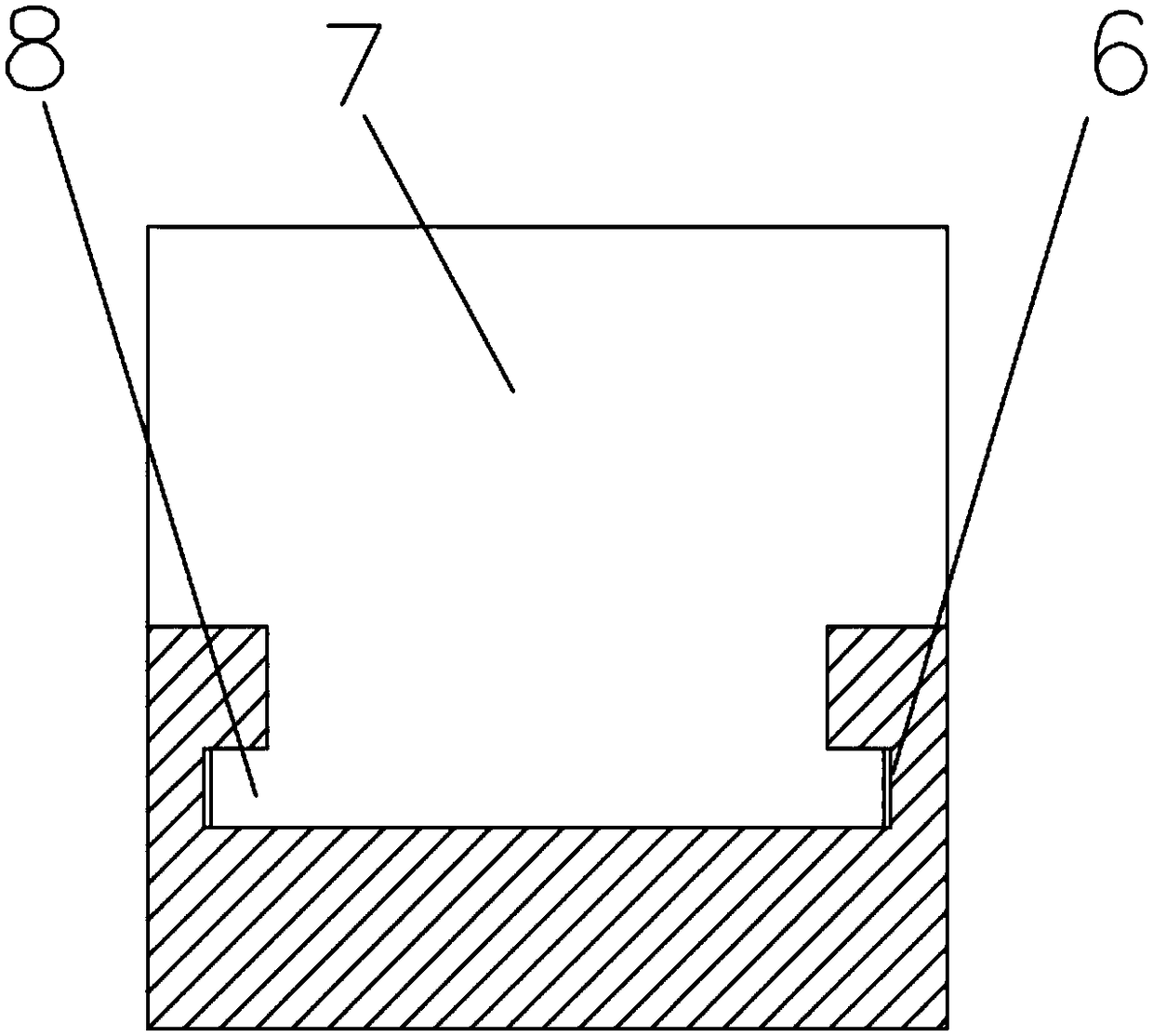

[0029] A cutting device for scrap steel processing, comprising an oil cylinder with a rectangular parallelepiped structure, a controller 2 with a square plate structure, and a cutting table; the cutting table includes a square fixed plate 3 and a horizontal frame 5 with a rectangular parallelepiped structure; A chute is opened in the middle, and guide grooves 6 are symmetrically provided on both sides of the chute. A square sliding plate 7 is fitted inside the chute, and side bumps 8 are symmetrically provided on both sides of the bottom of the sliding plate 7. The side protrusions 8 are slidably fitted in the guide grooves 6; the two ends of the guide grooves 6 are symmetrically provided with contact sensors 20 of block structure; the cutting table is vertically fixed and welded to the horizontal frame 5 At the left end of the fixed plate 3, a controller 2 is fixedly installed on the top of the fixed plate 3, a telescopic hydraulic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com