Nozzle assembly for 3D printer

A technology of 3D printers and nozzle components, applied in the field of 3D printing, can solve the problems of inconvenient removal, cumbersome use of materials, and restrictions on the popularization and use of 3D printers, and achieve the effect of expanding the scope of use and reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

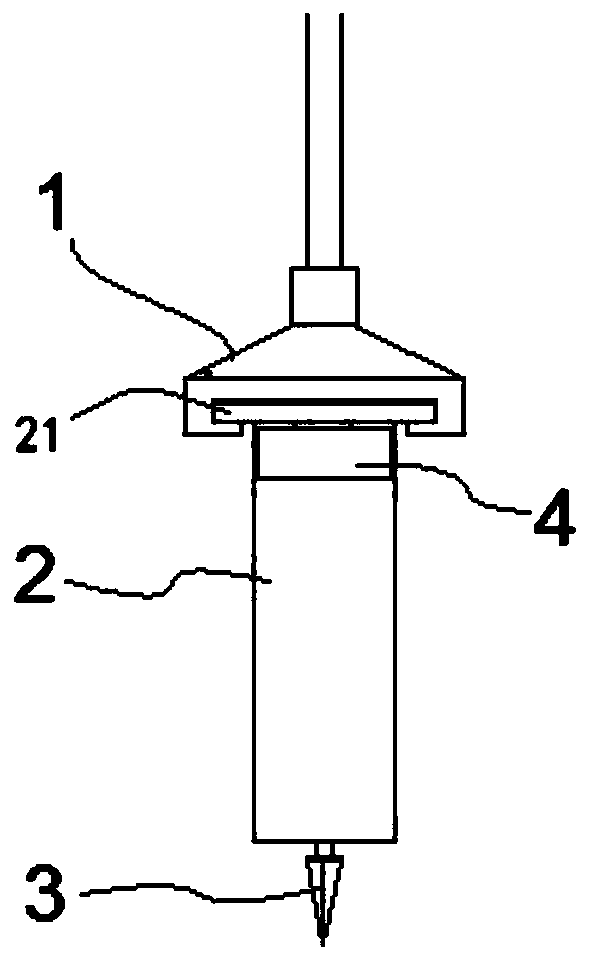

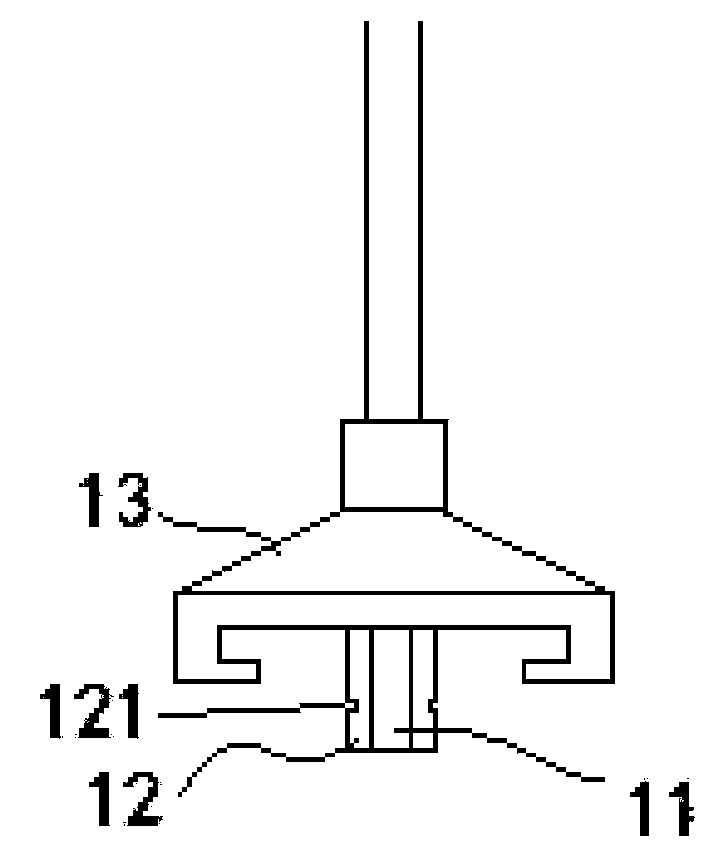

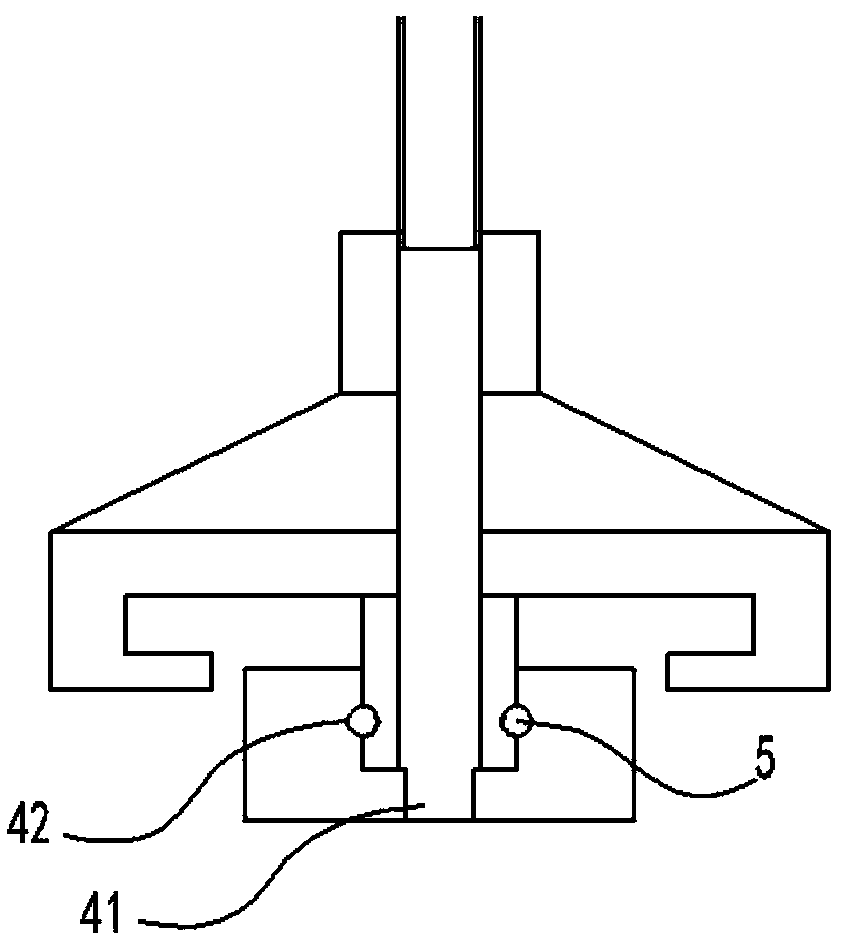

[0025] Such as figure 1 with image 3 As shown, the present invention provides a nozzle assembly for a 3D printer, including a dispenser adapter 1, a medical syringe barrel 2 and a printing needle 3, one end of the medical syringe barrel 2 is open, and the other end is equipped with the printing needle 3. The dispenser adapter 1 includes a plug 12 located at its end and a sealing piston 4 that is sleeved on the plug 12. The dispenser adapter 1 is provided with a passage that runs through the entire dispenser adapter 1. The hole 11 and the through hole 11 in the sealing piston 4 are provided with an air guide hole 41 penetrating through the sealing piston 4 , and the sealing piston 4 is in a sealing interference fit with the inner wall of the medical syringe barrel 2 and is detachably connected.

[0026] The end face of the sealing piston 4 close to the printing needle 3 is a flat plane. The advantage of this technical solution is that the sealing piston will not move during 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com