Method for processing workpiece

A technology of processed objects and processing methods, applied in the direction of semiconductor devices, other household appliances, electrical components, etc., can solve problems such as difficult fixing, and achieve the effect of efficient peeling and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

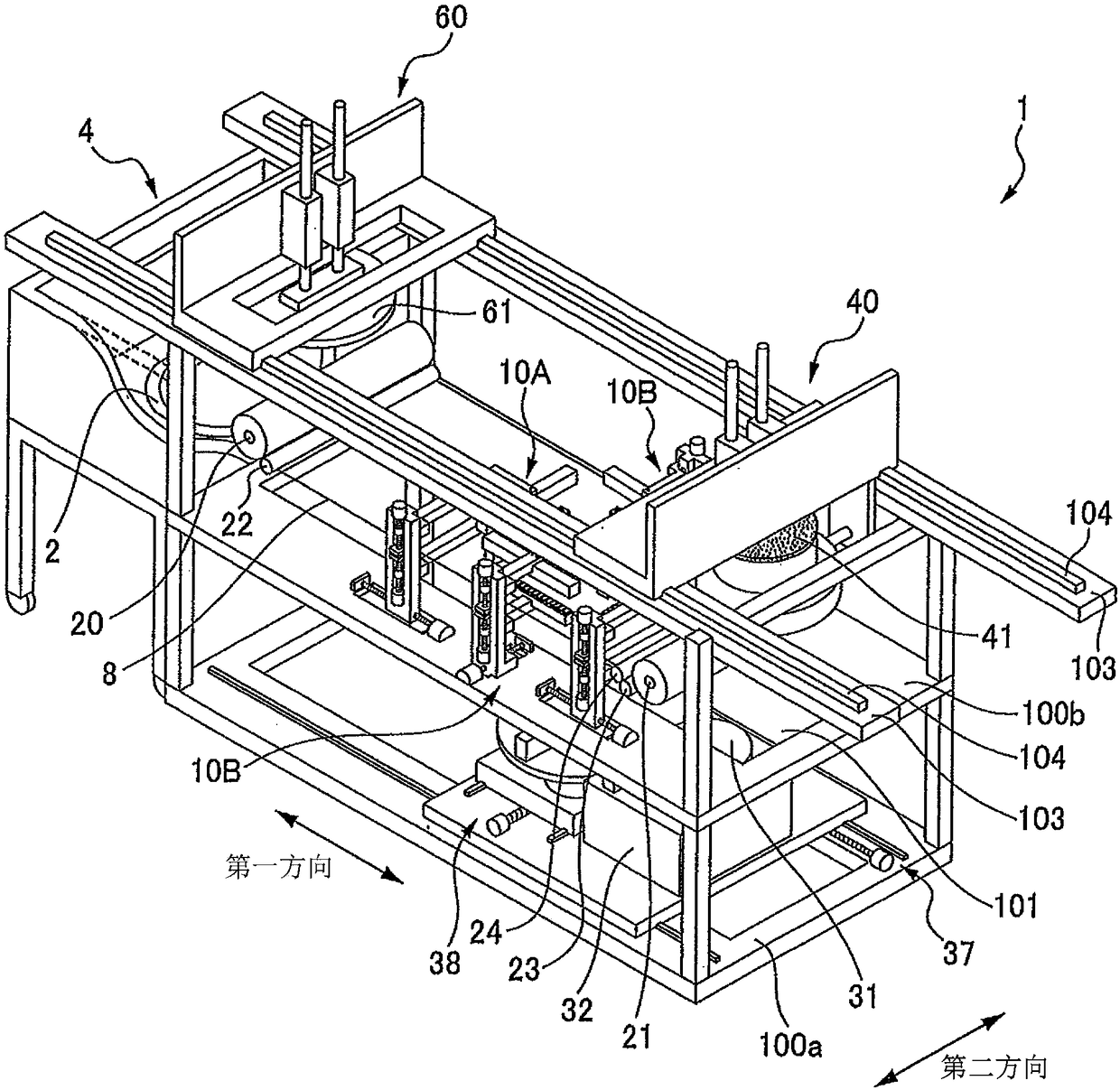

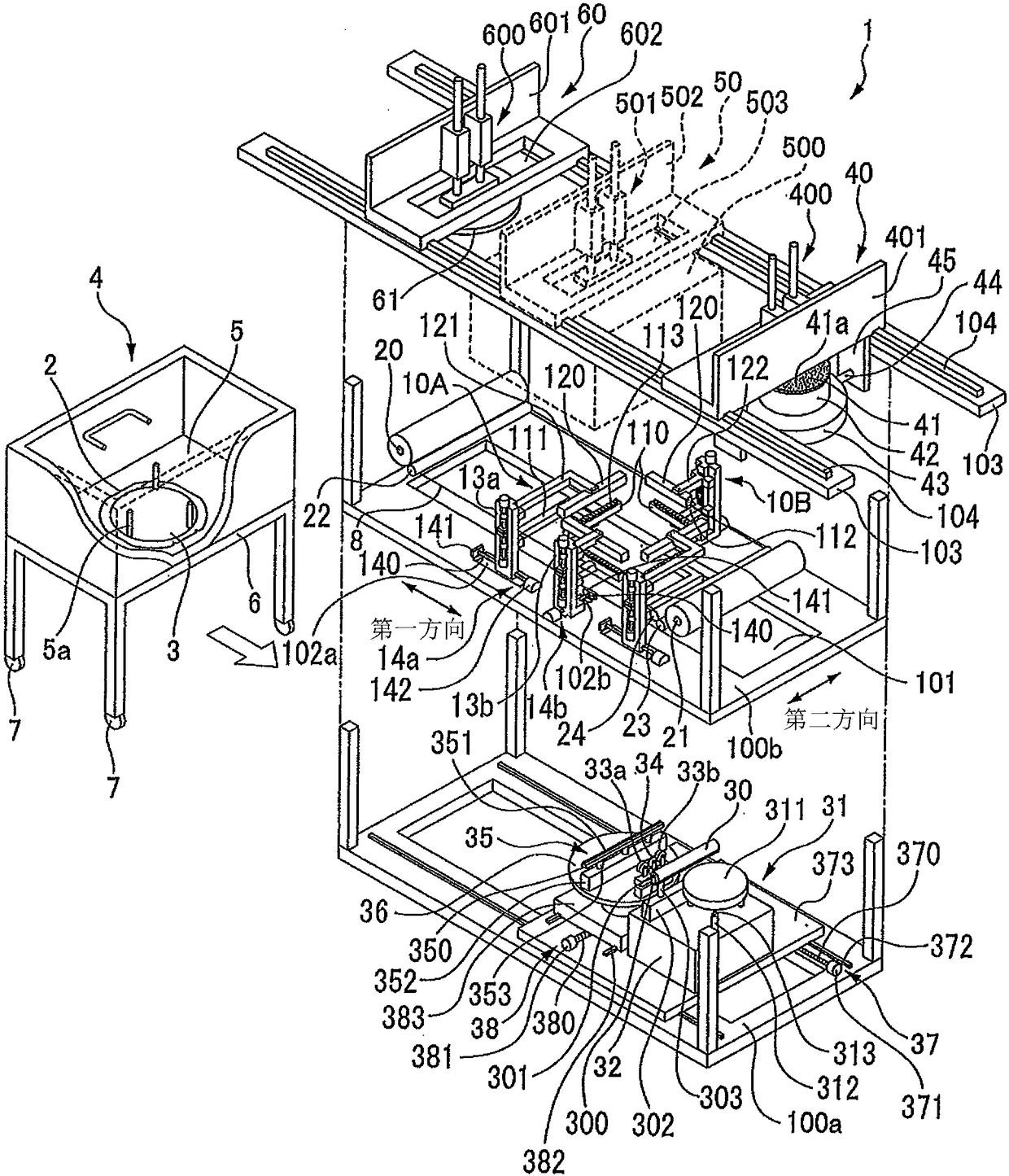

[0040] 1 expansion unit

[0041] figure 1The shown expanding device 1 is an example of a expanding device capable of expanding the expanding sheet 8 attached to the workpiece. The expansion device 1 has a three-layer structure, having: a device base 100a extending along the first direction at the first layer; a device base 100b extending along the first direction at the second layer; and extending along the first direction at the third layer. A pair of guide bases 103. An opening 101 for communication with the side of the device base 100a is formed in a central portion of the device base 100b. Guide rails 104 extending along the first direction are respectively laid on the pair of guide bases 103 . On the rear side of the device base 100a, 100b in the first direction, an annular frame providing assembly 4 is connected, and the annular frame providing assembly 4 is used to accommodate a plurality of figure 2 Ring frame 2 with opening 3 shown.

[0042] figure 2 The illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com