Milk and preparation method thereof

A technology of milk and milk, which is applied in the food field, can solve the problems of less nutrient loss milk, indestructible spores, nutrient loss, etc., and achieve the effect of excellent taste, good flavor and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

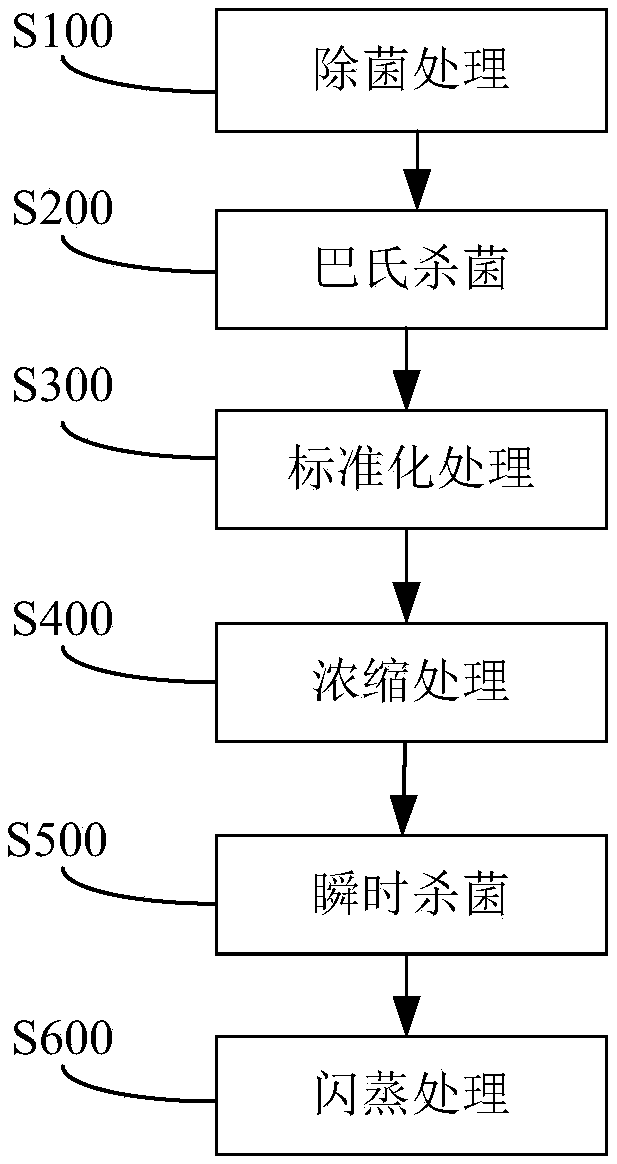

Method used

Image

Examples

Embodiment 1

[0056] Utilize the method for the embodiment of the present invention to prepare milk, specifically as follows:

[0057] 1. Raw materials:

[0058] Raw milk: 1000 kg.

[0059] 2. Preparation method:

[0060] (1) 1000 kg of fresh raw milk is passed through a sterilizing separator to remove a part of microorganisms to obtain sterilized milk;

[0061] (2) The sterilized milk is centrifuged by a centrifuge, and the pressure of the centrifuge is 3.0 bar, and part of the fat is removed to obtain skimmed milk;

[0062] (3) Preheat skimmed milk at 65°C, homogenize at 200 bar, pasteurize at 83°C for 15S, and cool to 45°C to obtain pasteurized milk;

[0063] (4) Standardize the pasteurized milk so that the fat content of the milk is 0.8%, and the protein content is 3.0%;

[0064] (5) Concentrating the standardized milk through the RO membrane to obtain concentrated milk with a fat content of 1.0% and a protein content of 3.7%, and the permeate is used for other purposes;

[0065] (...

Embodiment 2

[0073] Utilize the method for the embodiment of the present invention to prepare milk, specifically as follows:

[0074] 1. Raw materials:

[0075] Raw milk: 1000 kg;

[0076] 2. Preparation method:

[0077] (1) 1000 kg of fresh raw milk is passed through a sterilizing separator to remove a part of microorganisms to obtain sterilized milk;

[0078] (2) The sterilized milk is centrifuged by a centrifuge, and the pressure of the centrifuge is 3.0 bar, and part of the fat is removed to obtain skimmed milk;

[0079] (3) Preheat the skimmed milk at 70°C, homogenize at 210bar, pasteurize it at 85°C for 15S, and cool it to 50°C to obtain pasteurized milk;

[0080] (4) Standardize the pasteurized milk so that the fat content of the milk is 1.5%, and the protein content is 3.0%;

[0081] (5) Concentrate the standardized milk through RO to obtain concentrated milk with a fat content of 2.0% and a protein content of 4.5%, and the permeate is used for other purposes;

[0082] (6) Tem...

Embodiment 3

[0090] Utilize the method for the embodiment of the present invention to prepare milk, specifically as follows:

[0091] 1. Raw materials:

[0092] Raw milk: 1000 kg;

[0093] 2. Preparation method:

[0094] (1) 1000 kg of fresh raw milk is passed through a sterilizing separator to remove a part of microorganisms to obtain sterilized milk;

[0095] (2) The sterilized milk is centrifuged by a centrifuge, the pressure of the centrifuge is 3.5bar, and part of the fat is removed to obtain skimmed milk;

[0096] (3) Preheat skimmed milk at 74°C, homogenize at 230bar, pasteurize at 87°C for 15S, and cool to 55°C to obtain pasteurized milk;

[0097] (4) Standardize the pasteurized milk so that the fat content of the milk is 3.0%, and the protein content is 3.0%;

[0098] (5) Concentrate the standardized milk through the RO membrane to obtain concentrated milk with a fat content of 4.5% and a protein content of 4.5%, and the permeate is used for other purposes;

[0099] (6) Tempo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com