Ultra-fine powder ultrasonic linear screen

An ultra-fine powder, linear sieve technology, applied in the direction of sieve, solid separation, grid, etc., can solve the problem of easy collision and friction damage of powder, inability to superimpose multi-layer sieve powder with various particle sizes, etc. Good air tightness, excellent air tightness, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the content of the invention, features and effects of the present invention, the following examples are listed below for illustration.

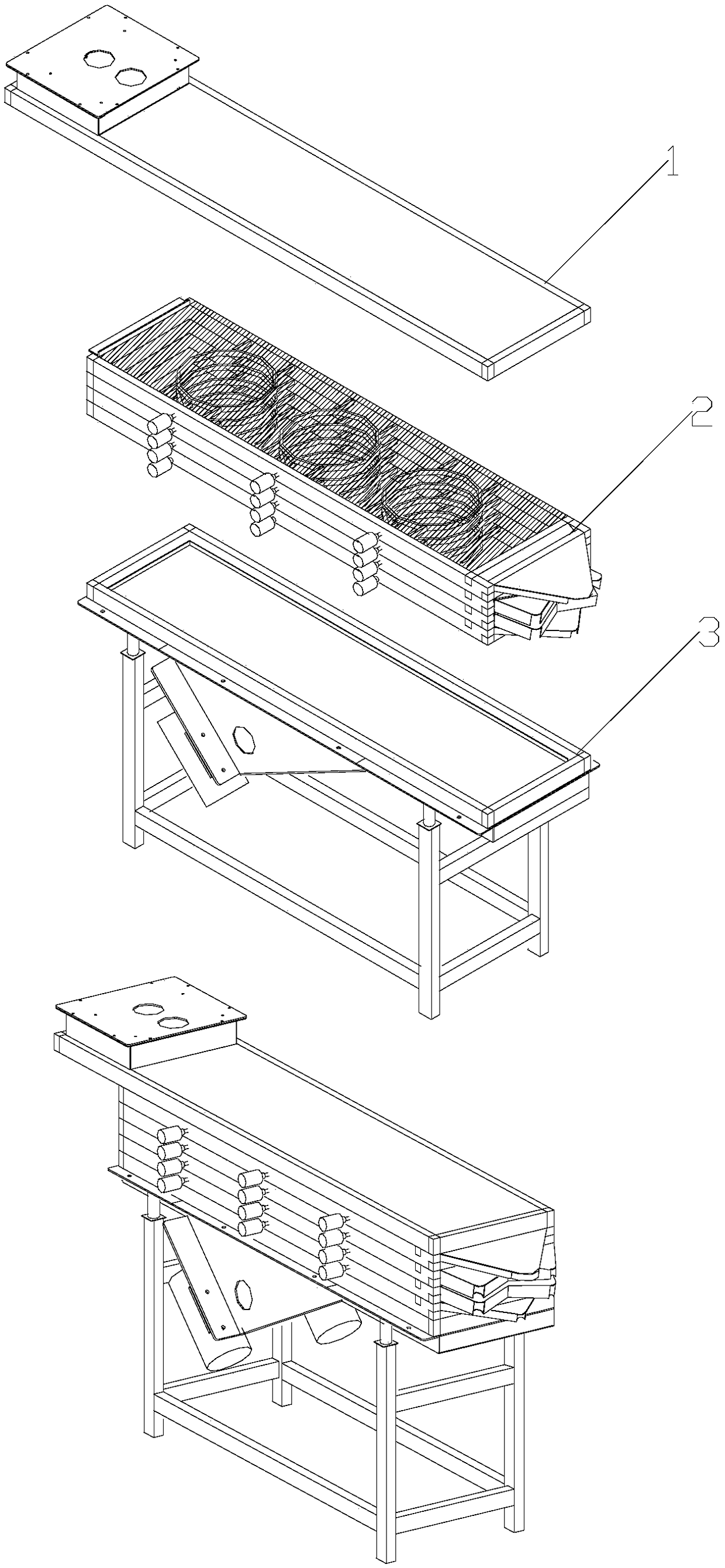

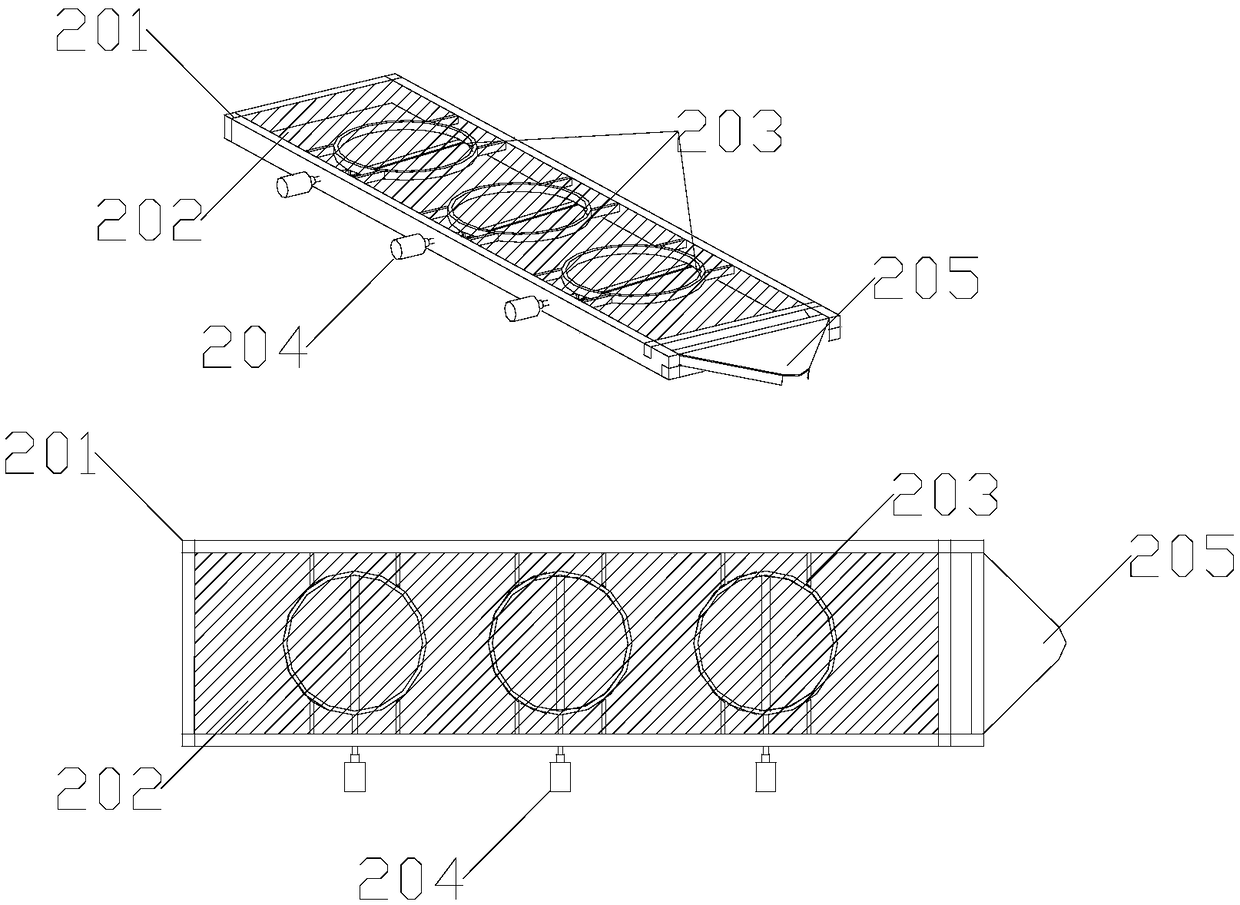

[0024] refer to Figure 1-4 , the technical scheme adopted in the present invention is as follows: a kind of superfine micropowder ultrasonic linear sieve, comprises feed plate 1, linear sieve group 2, vibrating support table 3, linear sieve group 2 is arranged on the upper surface of vibrating support table 3, feed plate 3 is set on the upper surface of the linear screen group 2. The linear screen group 2 is composed of several layers of linear screens superposed. Paste, there are sealing strips attached between the layers and the outer surface, forming a closed system with good airtightness as a whole;

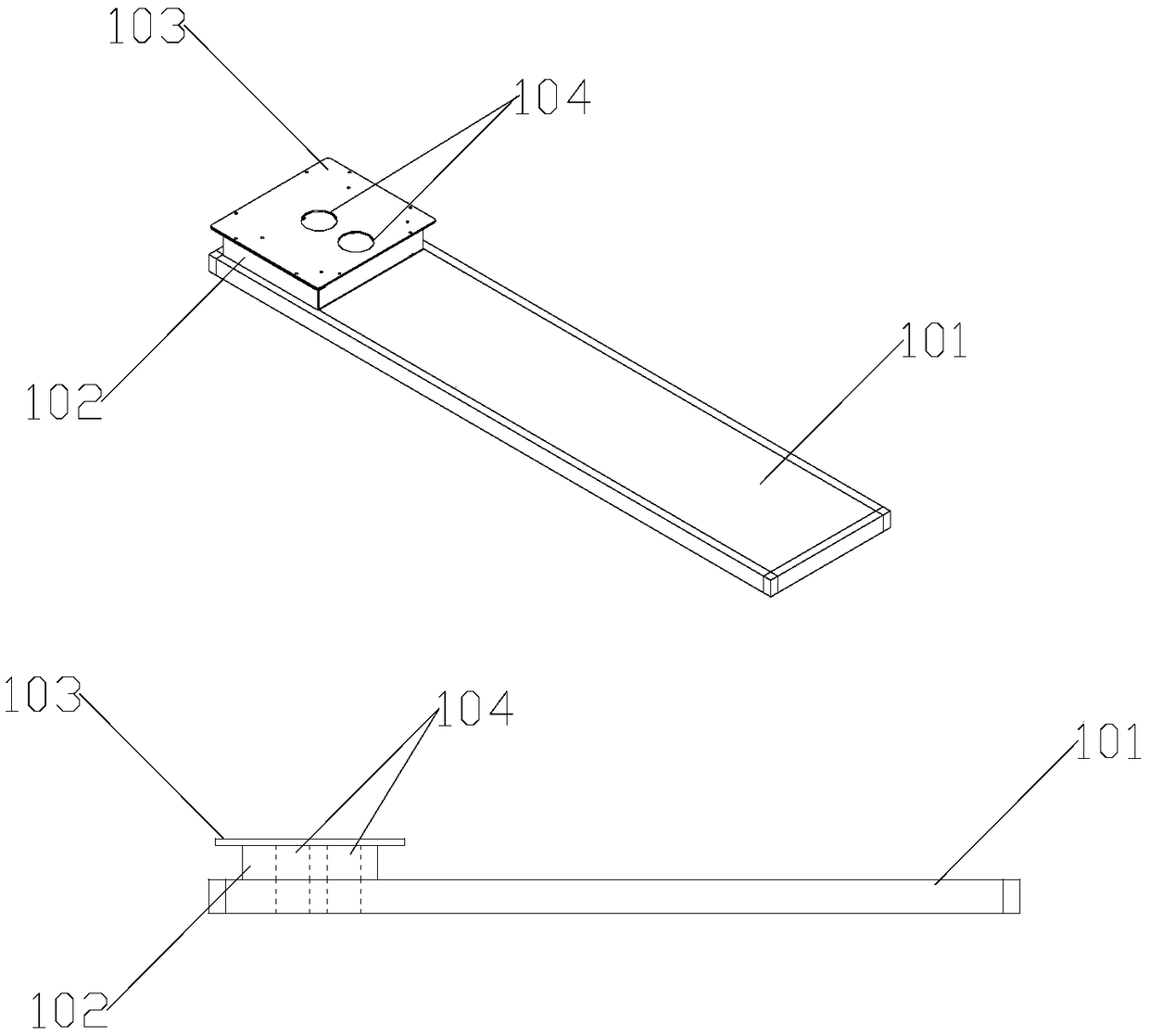

[0025] The feed plate 1 is composed of a cover plate 101, a cavity 102, a mounting plate 103, and a feed circular hole 104. The cover plate 101 is a cuboid, and a cuboid cavity is formed on the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com