Preparation method of large semi-closed inner cavity shell

A semi-closed, inner cavity technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as uneven wall thickness, scrapped castings, and complex inner cavity structure, so as to achieve uniform wall thickness and avoid steel breakout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a shell with a large semi-closed inner cavity. The large semi-closed inner cavity shell includes n structural units, and each structural unit is approximately a structure of revolution. When the number of structural units n is greater than or equal to two When , one of them is determined as the main structural unit, and the rest of the structural units and the main structural unit are in the habitual connection relationship. The side wall of each structural unit is an approximate rotary structure with an open bottom and a closed top. The pouring system is placed on the top of the main structural unit, which is the gripping part of the robot during the shell preparation process. The steps of the method include:

[0044] (1) prepare the wax mold of mold shell;

[0045] (2) configure slurry;

[0046] (3) Place the wax pattern prepared in step (1) into the slurry prepared in step (2) for dipping. After the surface of the wax pattern is covered with...

Embodiment 1

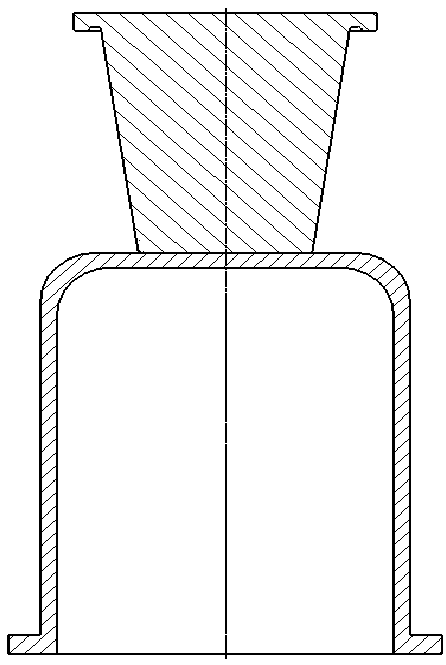

[0074] The large semi-enclosed inner cavity housing includes a structural unit, which is a rotary structure, and the structural unit is a U-shaped structure, and the side wall of the U-shaped structure is an approximate rotary structure, with an open bottom and a closed top.

[0075] The preparation method of this type shell is:

[0076] (1) Prepare the wax model of the shell, such as figure 1 shown;

[0077] (2) configuration slurry;

[0078] (3) Place the wax pattern prepared in step (1) into the slurry prepared in step (2) for dipping, after the surface of the wax pattern is covered with slurry, take out the wax pattern, and then control the slurry;

[0079] (4) Evenly shower sand on the surface of the wax mold with the slurry adhered in step (3), then let it stand and dry at a temperature of 22±3°C and a relative humidity of 40% to 65%;

[0080] (5) Place the product obtained in step (4) into the slurry prepared in step (2) for dipping. After all the slurry is covered, ...

Embodiment 2

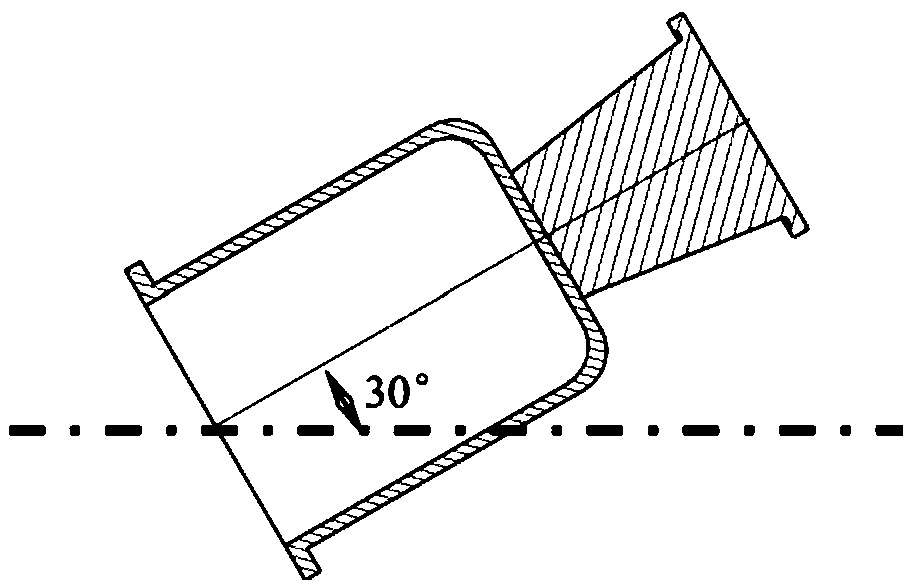

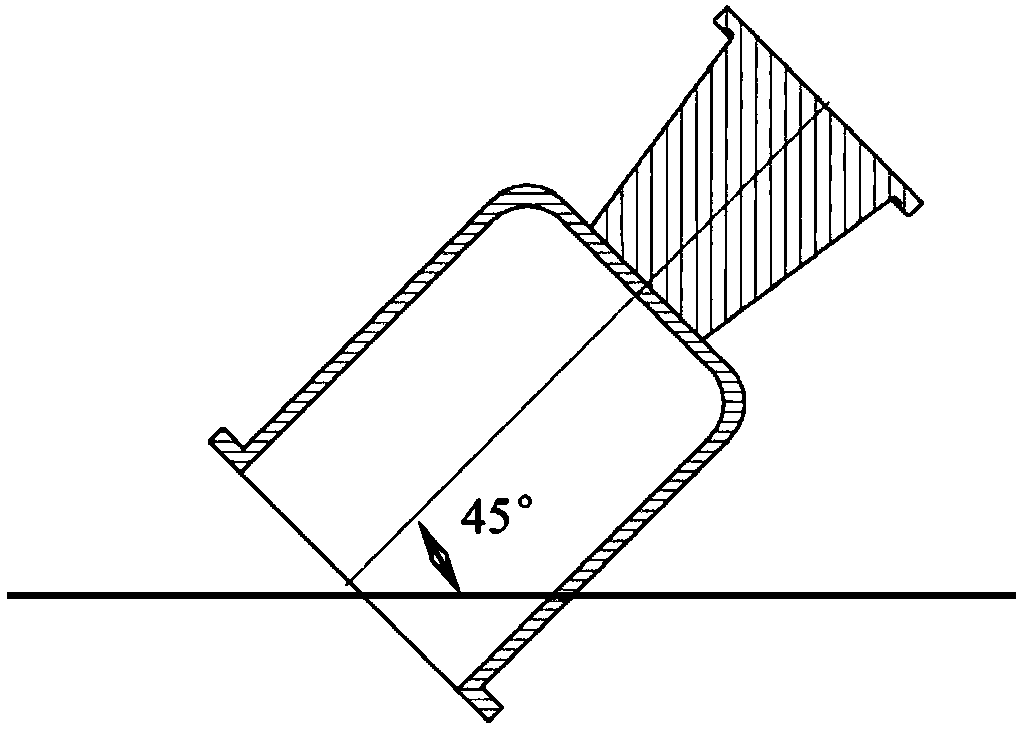

[0097] The large semi-closed inner cavity shell includes two structural units, both of which are a structure of revolution. The structural units are both U-shaped structures, and the two U-shaped structures are aligned at 90°, such as Figure 4 As shown, the side wall of the U-shaped structure is an approximate rotary structure with an open bottom and a closed top.

[0098] The preparation method of this type shell is:

[0099] (1) prepare the wax mold of mold shell;

[0100] (2) configuration slurry;

[0101] (3) Place the wax pattern prepared in step (1) into the slurry prepared in step (2) for dipping. After the surface of the wax pattern is covered with slurry, take out the wax pattern and then control the slurry; wax pattern control The direction and angle of slurry placement ensure uniform slurry on the surface;

[0102] (4) Evenly shower sand on the surface of the wax mold with the slurry adhered in step (3), then let it stand and dry at a temperature of 22±3°C and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com