Tightening and conveying system of rear axle assembly mixed-model production line

A conveying system and production line technology, applied in metal processing, workpiece clamping devices, metal processing equipment, etc., can solve the problems of increased pick-up distance for employees, waste of waiting time for employees, and reduced hourly output, etc., to achieve simple structure and economical man-hours and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

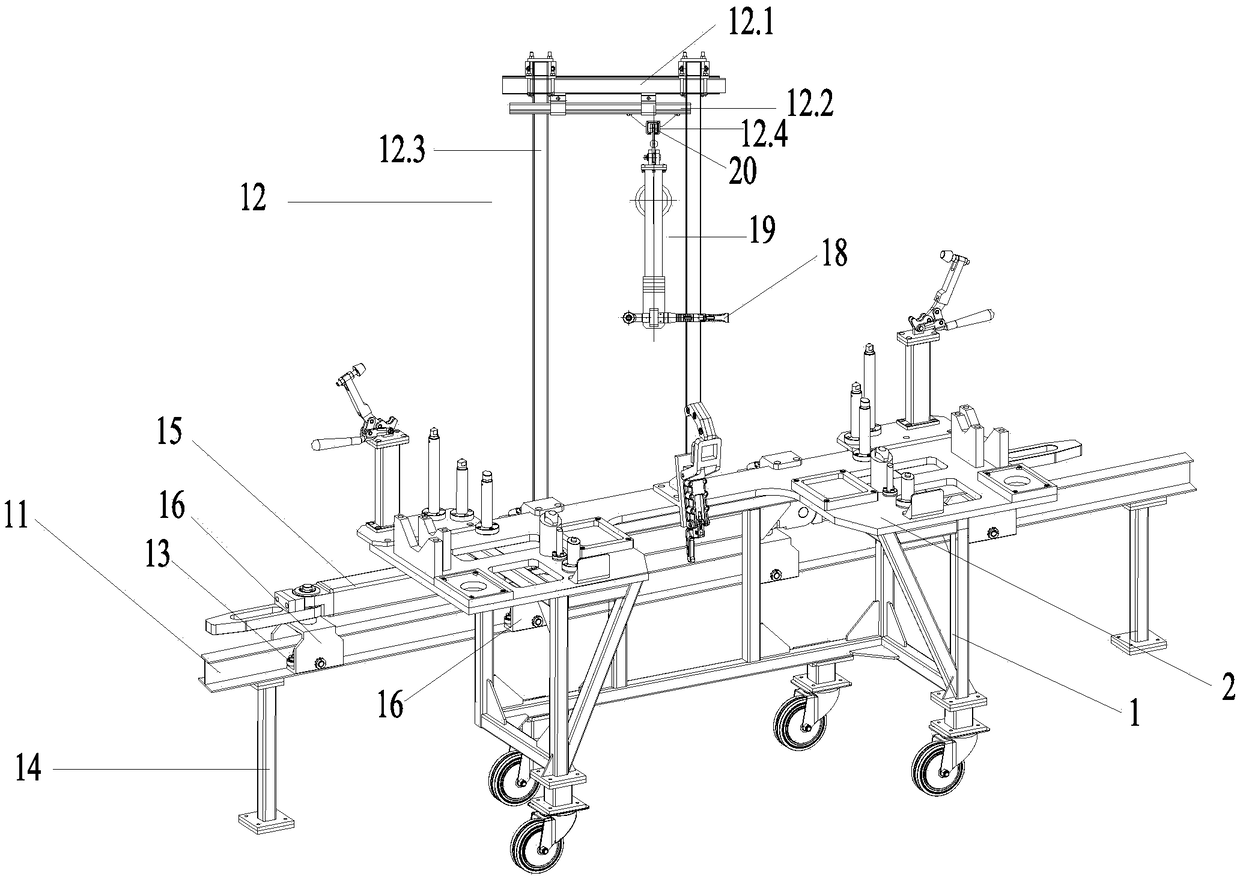

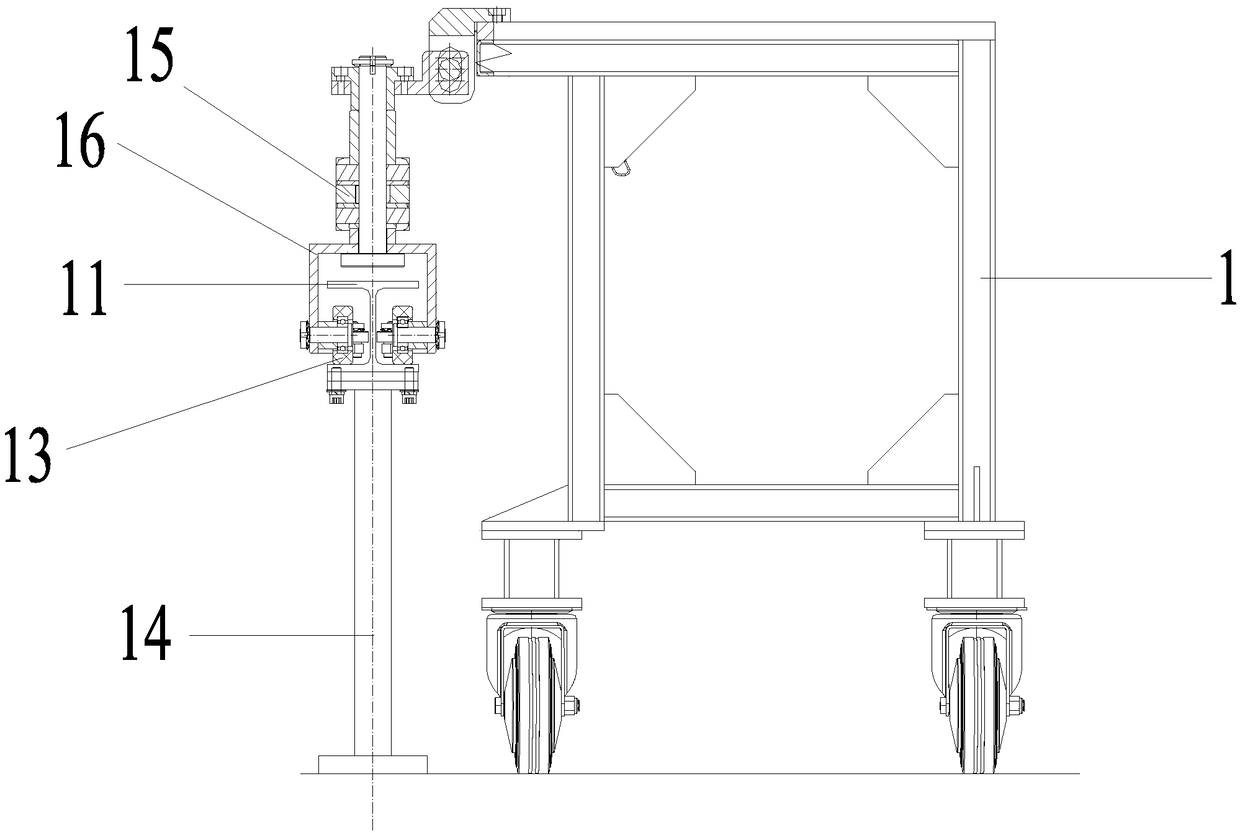

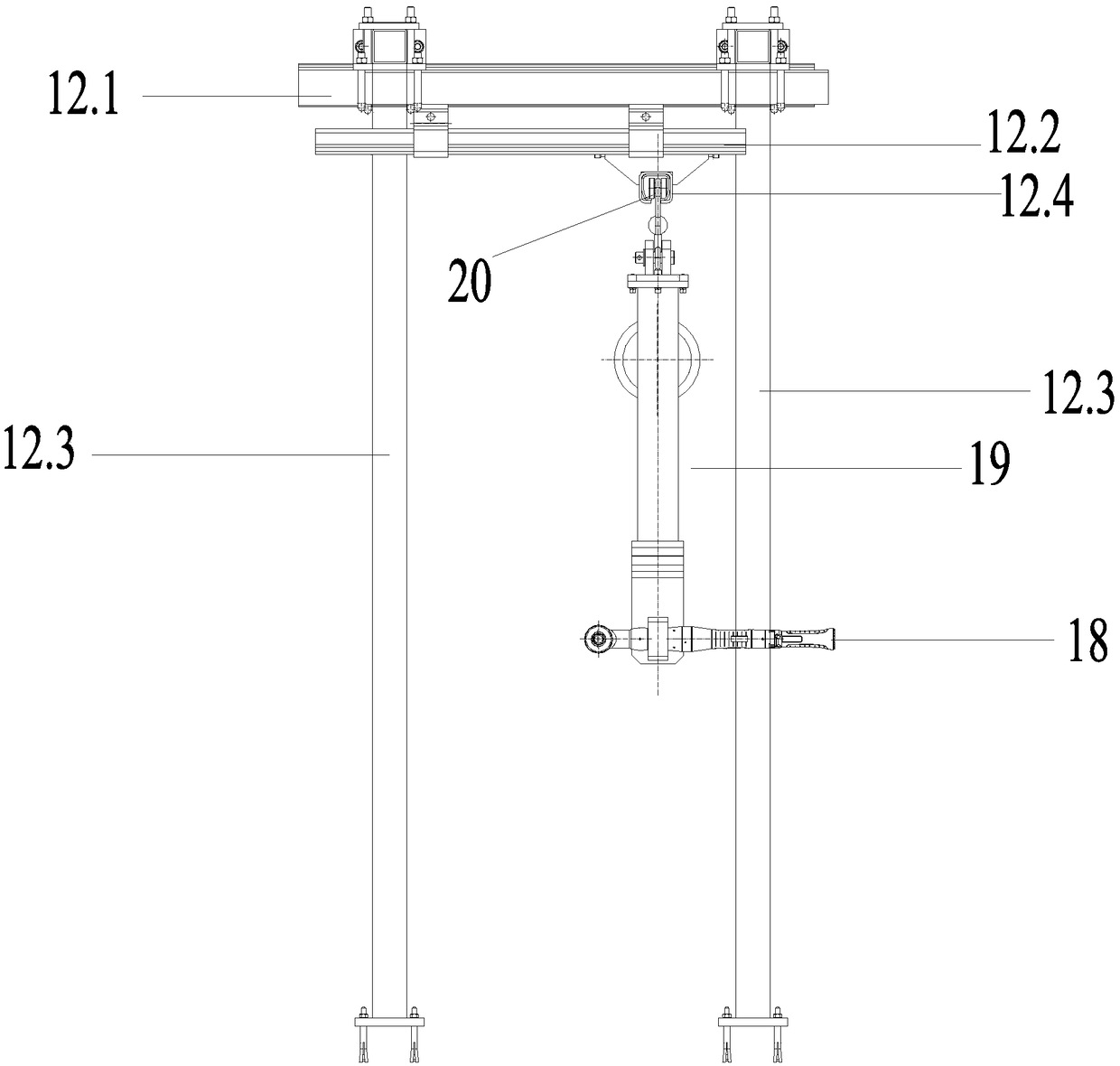

[0024] Such as figure 1 The tightening conveying system of the rear axle assembly mixed-flow production line shown in —5 includes a frame 1 with a pulley at the bottom, a tray 2 above the frame 1, and a quick clip for clamping the rear axle assembly on the tray 2. The positioning pin supporting the rear axle assembly also includes a guide rail 11 arranged along the conveying direction of the mixed flow production line of the rear axle assembly and an electric tightening device 12 arranged at the tightening station of the mixed flow production line of the rear axle assembly, connected under the tray 2 There are guide rollers 13 that cooperate with the guide rail 11. The electric tightening device 12 includes a first guide rail 12.1 located above the tray 2 and parallel to the guide rail 11 and a sliding bracket 12.2 arranged on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com