Polymethyl methacrylate mold for manufacturing complex-section tunnel lining model

A plexiglass, complex section technology, used in manufacturing tools, ceramic molding machines, etc., can solve the problems of difficult repeated use and accurate molding, uneven model section, low mold removal success rate, etc. High and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

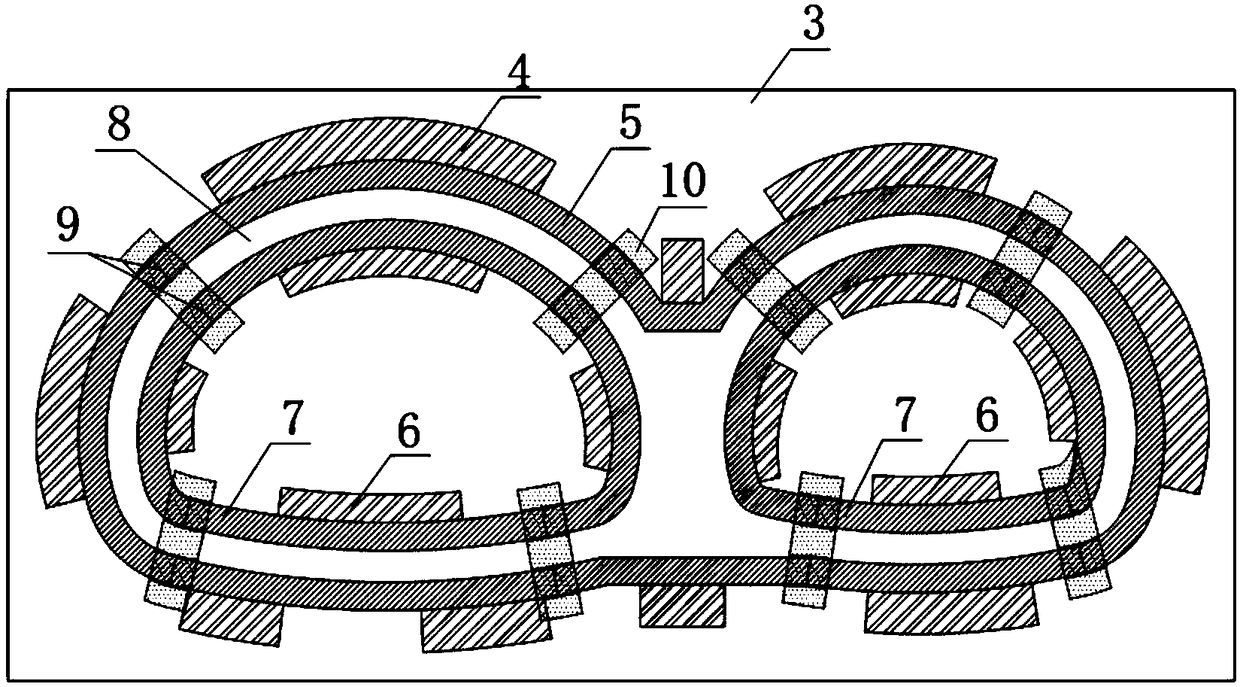

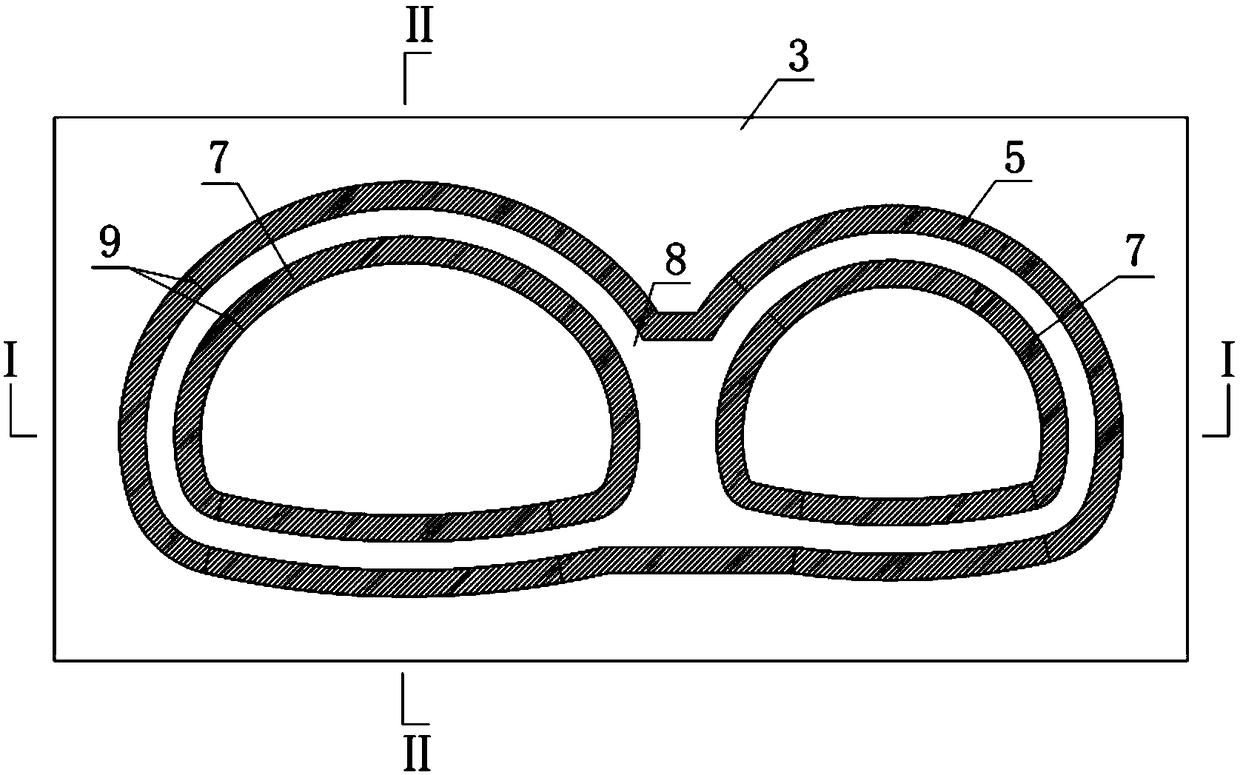

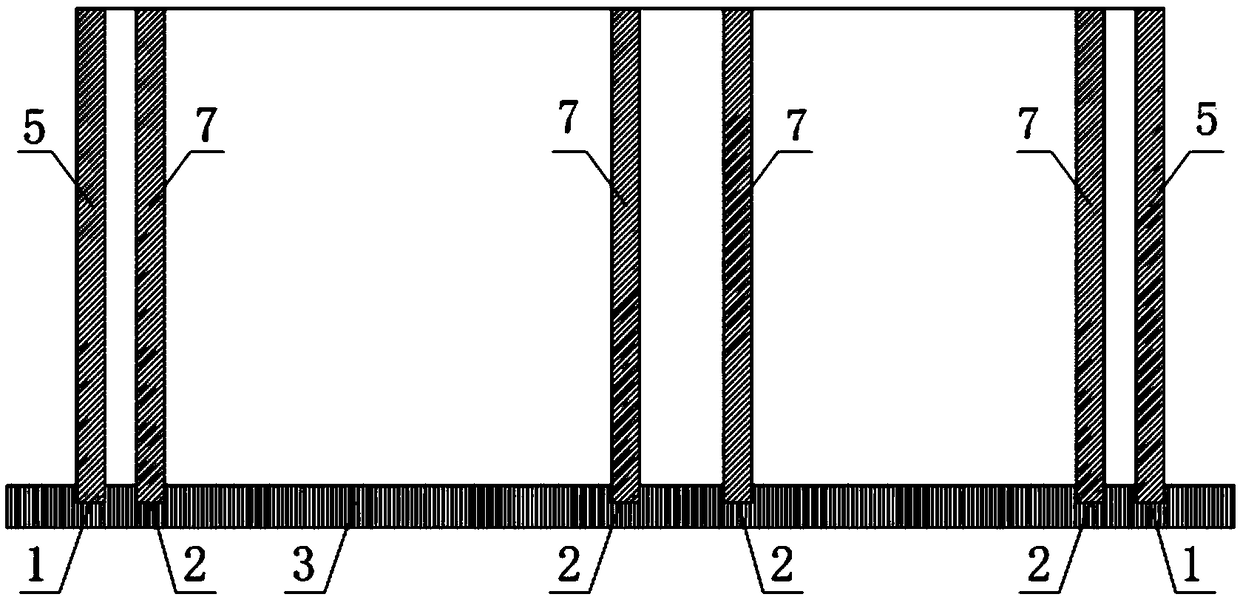

[0035] to combine Figure 1 to Figure 14 Described a kind of plexiglass mold for making the tunnel lining model of complex section, comprises the plexiglass base 3 that is provided with outer mold slot 1, one or more inner mold slots 2, is placed on the plexiglass base 3 respectively and Outer mold slot 1 , plexiglass outer mold 5 fitted in inner mold slot 2 , one or more plexiglass inner molds 7 inside the plexiglass outer mold 5 . There is a tunnel lining model pouring groove 8 between the plexiglass inner mold 7 and the plexiglass outer mold 5 .

[0036] exist figure 1 In the shown embodiment, the plexiglass outer mold 5 is a closed cylindrical body composed of eight curved wall columnar outer formworks with outside handles 4, and the plexiglass inner mold 7 is made of four pieces with inside handles 6. A closed cylindrical body composed of a curved wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com