Movable 3D printing device

A 3D printing and mobile technology, applied to 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost of 3D printing devices, low exposure resolution of projectors, poor light transmission of liquid crystal panels, etc., to achieve Good light transmittance, high resolution, less quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

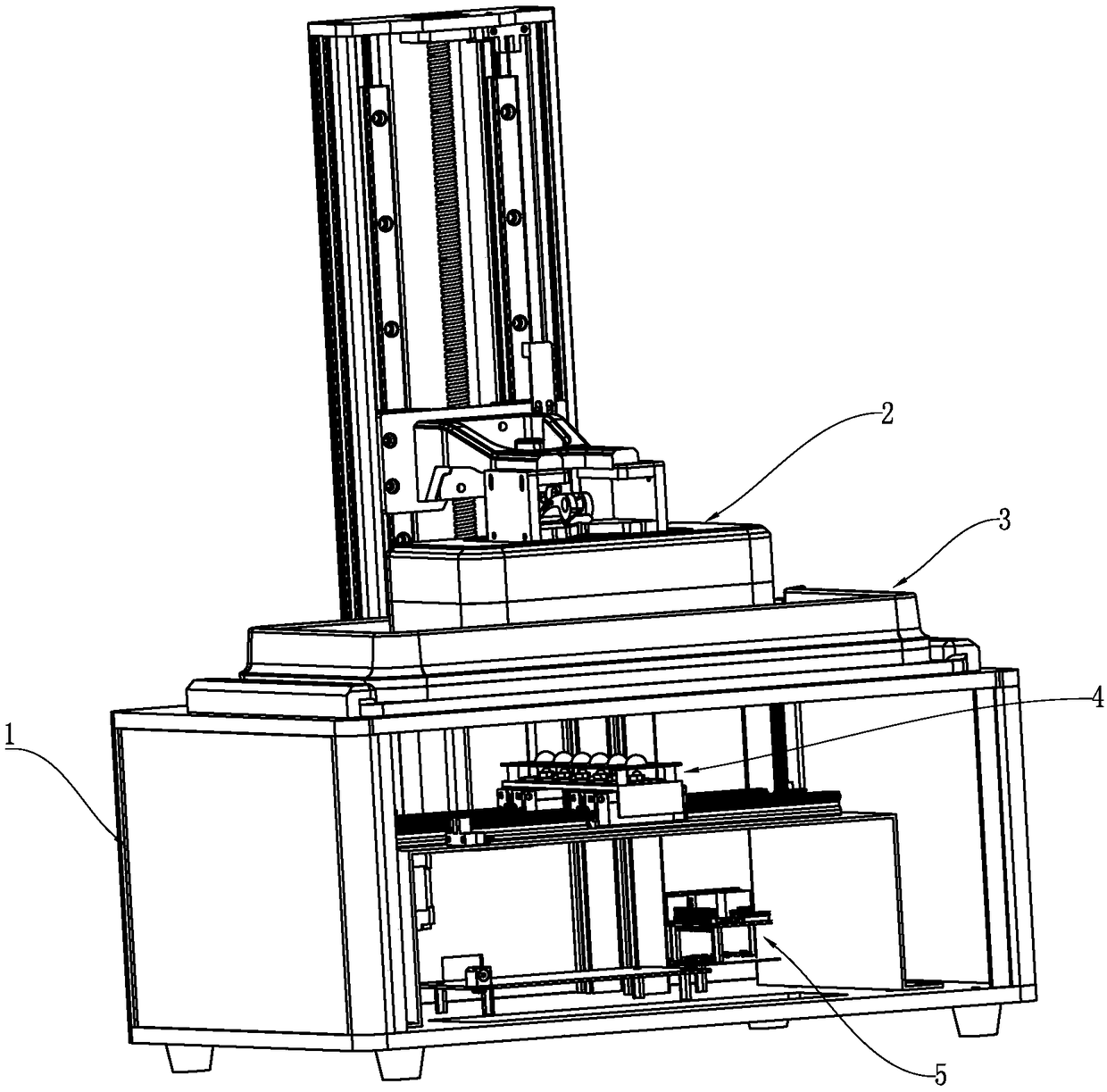

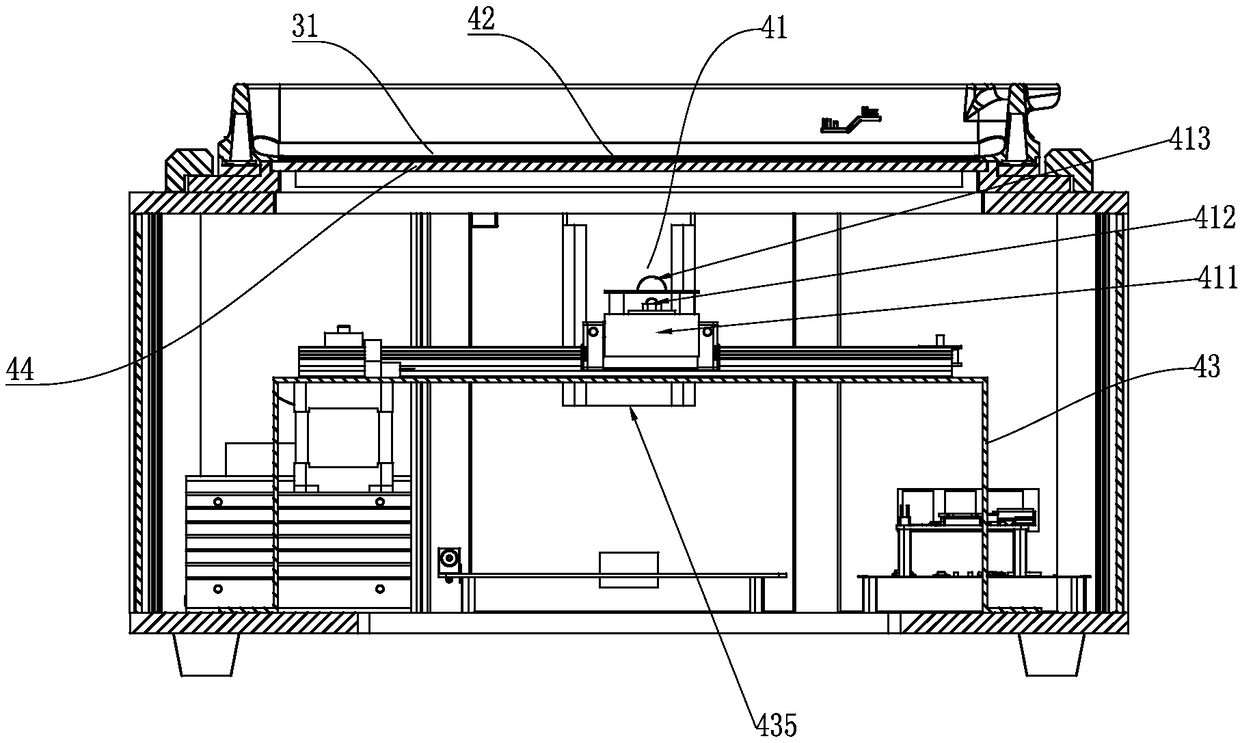

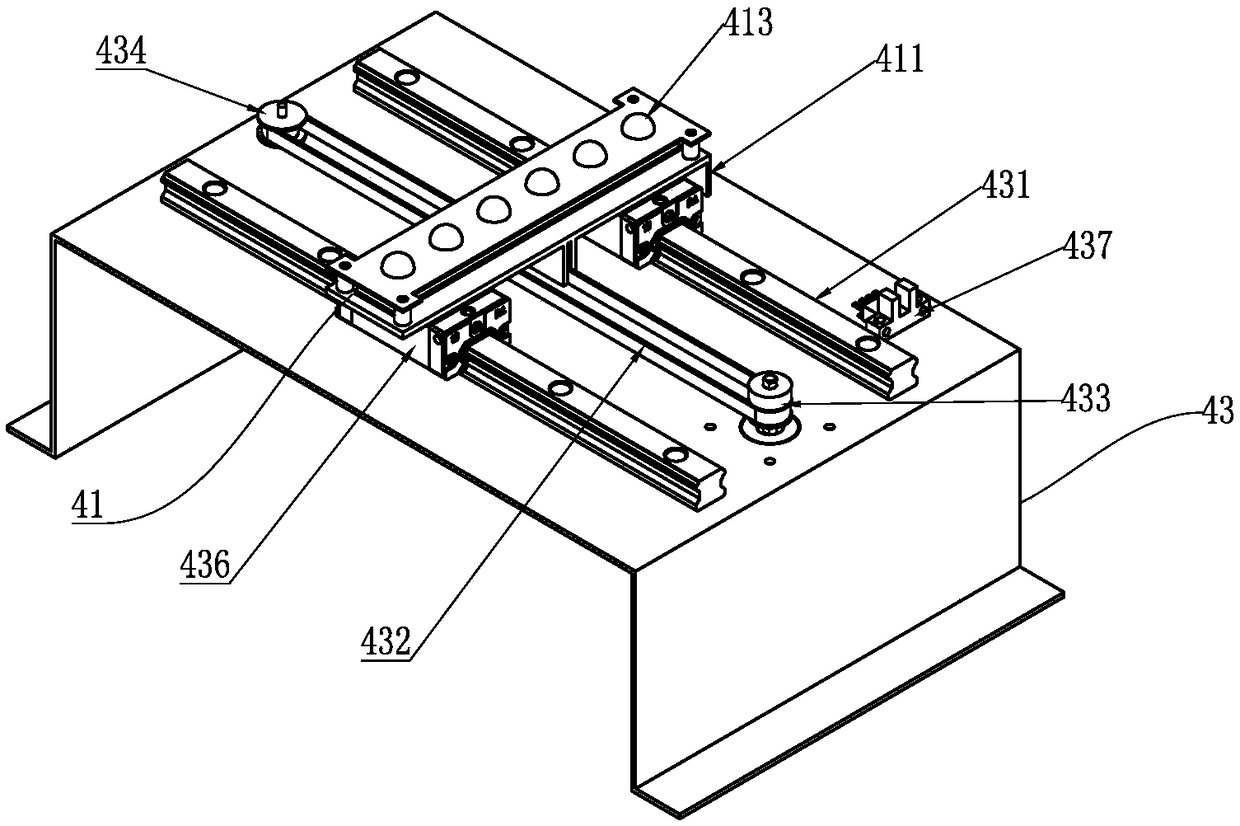

[0025] like Figure 1-3 As shown, a mobile 3D printing device includes a printing mechanism 2 installed on a base 1 , a liquid holding mechanism 3 , an exposure mechanism 4 and a control mechanism 5 . The exposure mechanism 4 includes a bracket 43, a light source assembly 41 slidably arranged on the bracket 43, and a liquid crystal panel 42 arranged in the light source emission direction of the light source assembly 41. The light emitted by the light source assembly is projected to the 3D printing mechanism through the liquid crystal panel 42. At the bottom of the material tank 31 , the control mechanism 5 controls various actions of the exposure mechanism 4 .

[0026] In this embodiment, the light source assembly 41 is strip-shaped, and includes a heat dissipation base 411 for heat dissipation of the light source, a light source 412 mounted on the heat dissipation base 411 , and an optical lens 413 located above the light source 412 . The light source 412 is composed of a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com