Preparation method of pulling-extruded polyurethane fiber reinforced composite material

A reinforced composite material and polyurethane fiber technology, which is applied in the field of preparation of pultruded polyurethane fiber reinforced composite materials, can solve the problems of slow solidification speed, mold blockage, fast solidification speed, etc., to improve the pultrusion speed, avoid poor fluidity, The effect of convenient start-stop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

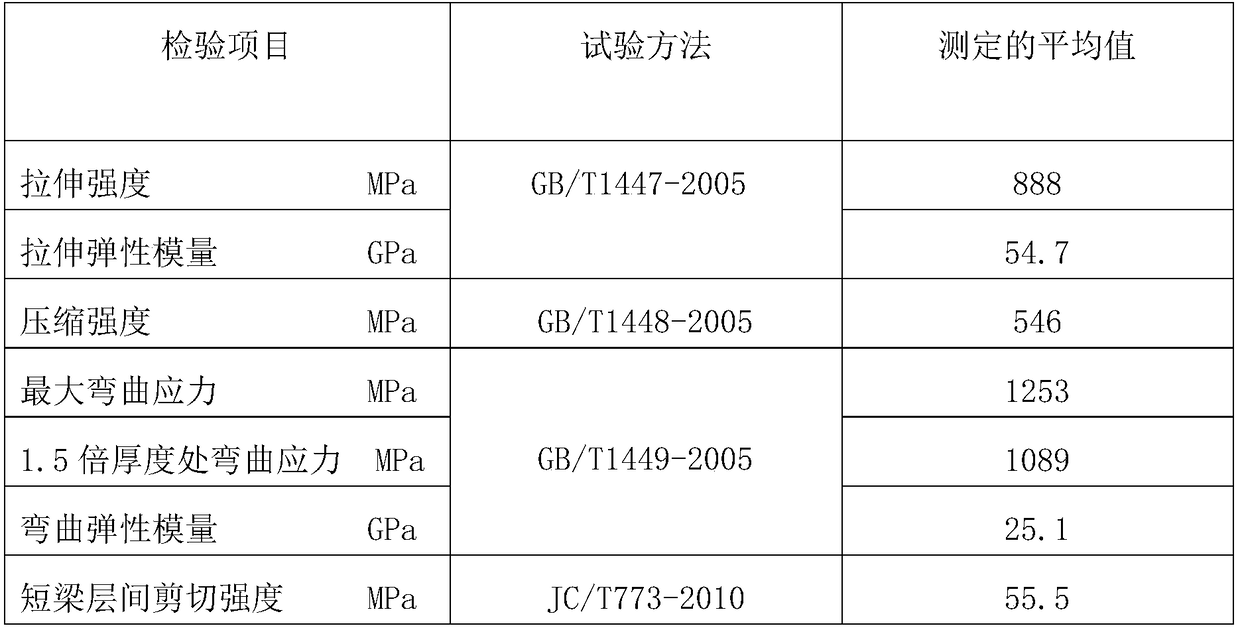

Examples

Embodiment 1

[0019] The preparation method of the pultruded polyurethane fiber reinforced composite material of the present invention comprises the following steps:

[0020] Step 1, passing the fiber mat around the continuous fiber and the head of the continuous fiber with a mass fraction of 50% sequentially through the track guide and the mold, the continuous fiber includes glass fiber, aramid fiber, basalt fiber, carbon fiber, Metal fibers and any mixture thereof, the fiber mats are glass fiber mats, aramid fiber mats, basalt fiber mats, carbon fiber mats, metal fiber mats, etc. The track guide is located upstream of the mould, and the track guide is provided with at least one first through hole for the continuous fiber to pass through, and the track guide is also provided with at least one second through hole for the fiber mat to pass through, These second through holes are located around the first through holes, wherein the continuous fiber passes through the first through holes and th...

Embodiment 2

[0028] The differences between this embodiment and Embodiment 1 are as follows:

[0029] In step 1, the fiber mat positioned around the continuous fiber and the head of the continuous fiber with a mass fraction of 60% pass through the track yarn guide and the mold successively;

[0030] In step 2, the pressure of the polyurethane resin injected into the glue soaking zone of the mold is 0.15MPa, and the polyurethane resin is injected into the glue soaking zone at a speed of 563ml / min.

[0031] In step 3, the heating temperature in the preheating zone is 100°C, and the heating temperature in the gelling zone is 180°C.

[0032] In step 4, the pulling speed of the pulling device is 1500cm / min.

Embodiment 3

[0034] The differences between this embodiment and Embodiment 1 are as follows:

[0035] In step 1, the fiber mat located around the continuous fiber and the head of the continuous fiber with a mass fraction of 70% are sequentially passed through the track guide and the mold.

[0036] In step 2, the pressure of the polyurethane resin injected into the glue soaking zone of the mold is 0.17MPa, and the polyurethane resin is injected into the glue soaking zone at a speed of 233ml / min.

[0037] In step 3, the heating temperature in the preheating zone is 90°C, and the heating temperature in the gelling zone is 175°C.

[0038] In step 4, the pulling speed of the pulling device is 1240 cm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com