Pre-drying and curing mechanism, silk-screen printing machine and printing method

A screen printing machine and screen printing technology, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of interfering with the orientation of magnetic pigment flakes and affecting the effect of luster and optical change, achieving high anti-counterfeiting value, Good luster light change effect, fast curing and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

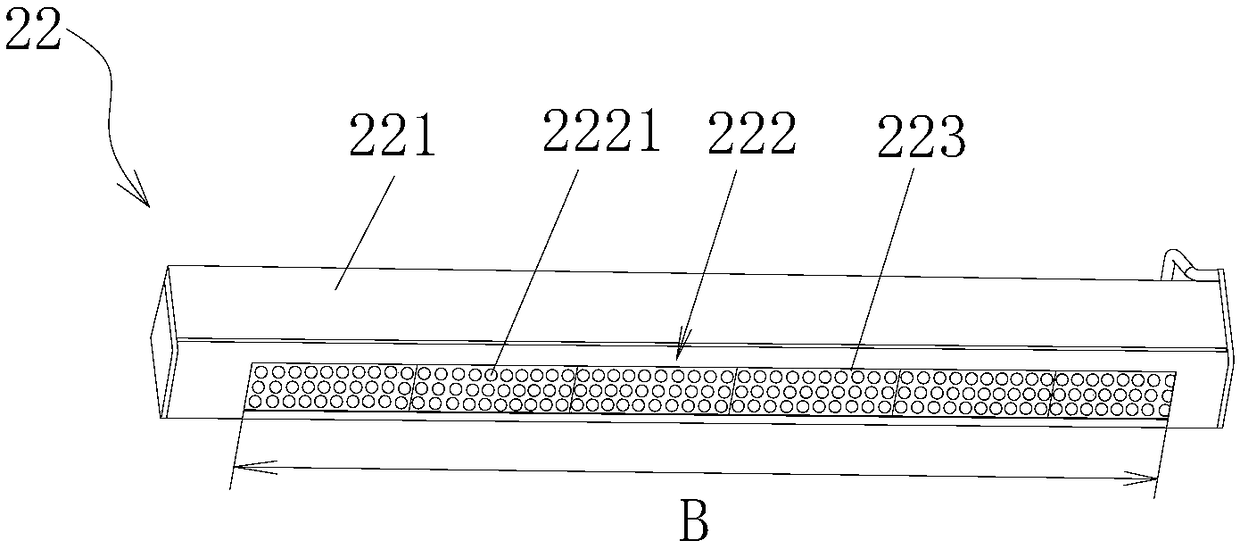

[0037] Such as image 3 As shown, the present invention provides a pre-drying and curing mechanism 22, the pre-drying and curing mechanism 22 has a packaging case 221 and a plurality of UV-LED array modules 222 arranged in the packaging case 221, the plurality of The UV-LED array modules 222 are arranged side by side along the length direction of the package housing 221, each of the UV-LED array modules 222 has a plurality of UV-LED lamp beads 2221, and each of the UV-LED array modules 222 The plurality of UV-LED lamp beads 2221 are arranged in multiple rows along the width direction of the UV-LED array module 222 , and are arranged in multiple columns along the length direction of the UV-LED array module 222 .

[0038] Specifically, the encapsulation housing 221 is generally in the shape of a cuboid, and a plurality of UV-LED array modules 222 are arranged in it, and one side of the encapsulation housing 221 is sealed with quartz glass 223, and these UV-LED array modules 222 ...

Embodiment approach 2

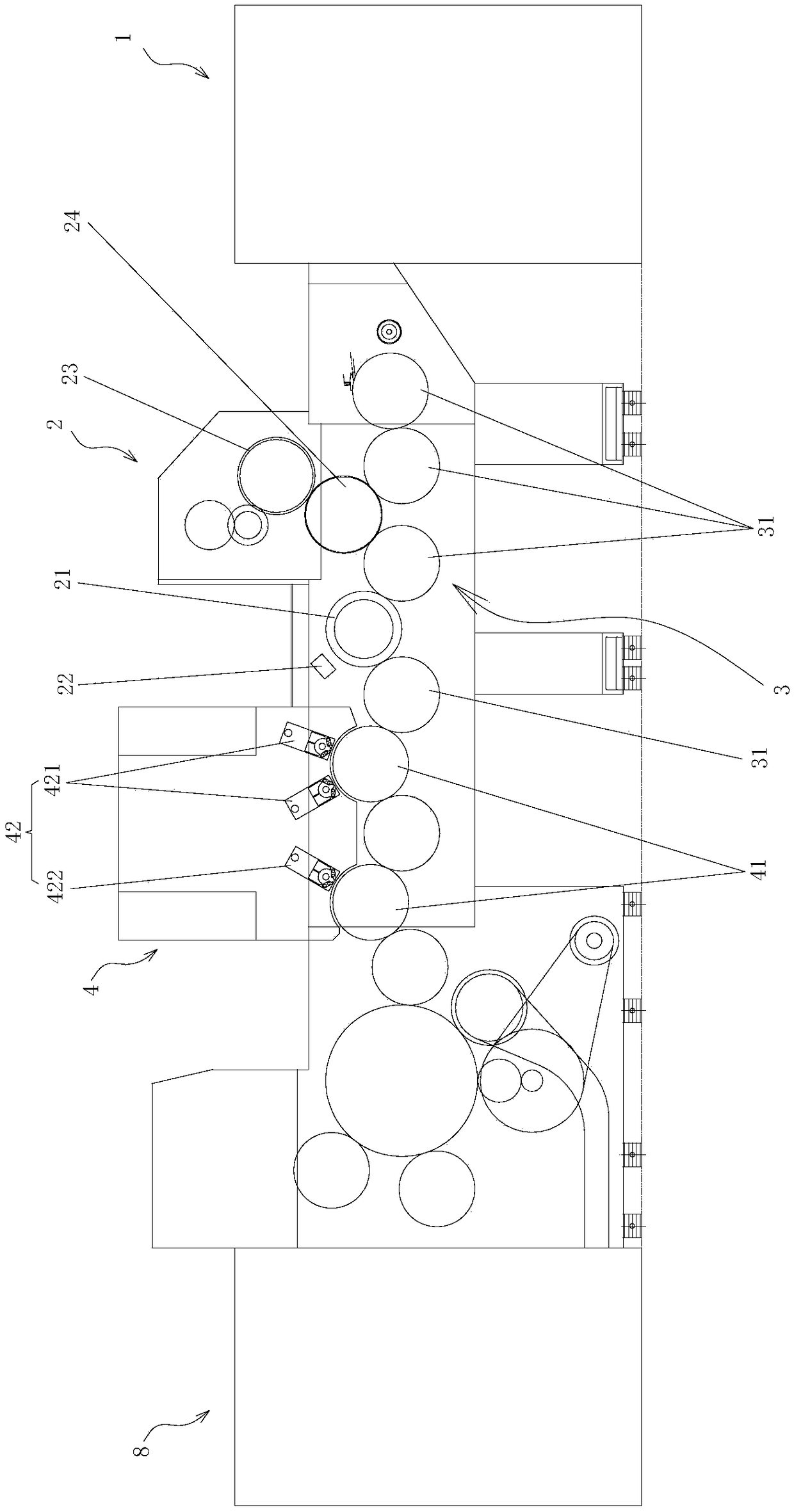

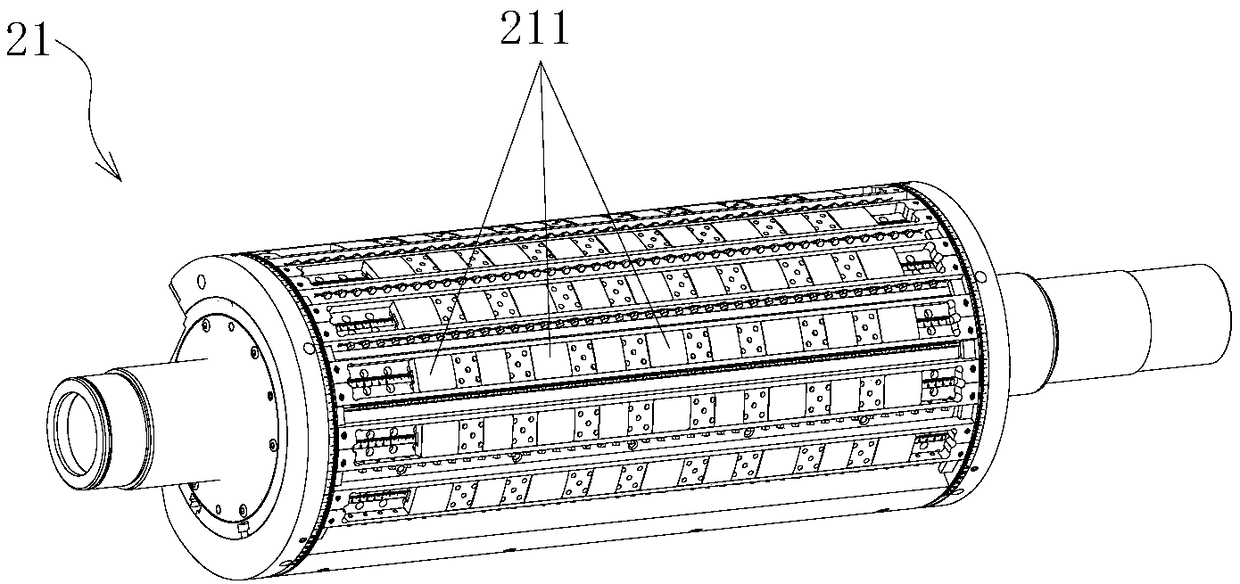

[0043] Such as figure 1 As shown, the present invention provides a screen printing machine, which includes a conveying part 1, a screen printing mechanism 2, a conveying mechanism 3 and a drying and curing mechanism 4, wherein: the conveying part 1 is used to convey a sheet substrate; The screen printing mechanism 2 is used to receive the sheet substrate and emboss ink or varnish carrier on the sheet substrate to form a substrate; the screen printing mechanism 2 has a magnetized cylinder 21, and the magnetized cylinder 21 has a magnetic field generator 211 capable of magnetizing the ink or varnish carrier; a pre-drying curing mechanism 22 capable of pre-drying and curing the substrate is provided near the magnetized cylinder 21; A plurality of conveying cylinders 31 of the substrate, the magnetized cylinder 21 is rollingly matched with the conveying cylinder 31; the drying and curing mechanism 4 has a drying cylinder 41 and a drying and curing device 42 arranged close to the d...

Embodiment approach 3

[0065] Such as Figure 1 to Figure 6 As shown, the present invention also provides a printing method, the printing method is implemented using the screen printing machine described in Embodiment 2, and the printing method includes the following steps:

[0066] Step S1: the sheet substrate is conveyed to the screen printing mechanism 2 by the conveying part 1, and after passing through the screen printing mechanism 2, ink or varnish carrier is embossed on the sheet substrate to form a printing substrate thing;

[0067] Step S2: The substrate is transported to the magnetized cylinder 21 of the screen printing mechanism 2 through the conveying mechanism 3, while the ink or varnish carrier on the substrate is magnetized and positioned, it passes through the magnetized cylinder 21 with the magnetized cylinder. The pre-drying and curing mechanism 22 arranged opposite to 21 performs pre-drying and curing on the magnetized substrate;

[0068] Step S3: After the printed matter is mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com