Cement applicator with hollow barrel on delivery plunger

A technology of bone cement and plunger, which is applied in the equipment field of bone cement paste, can solve the problems of bone cement paste consistency change, mixing ratio change, etc., and achieve the effect of large uniformity and sufficient stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

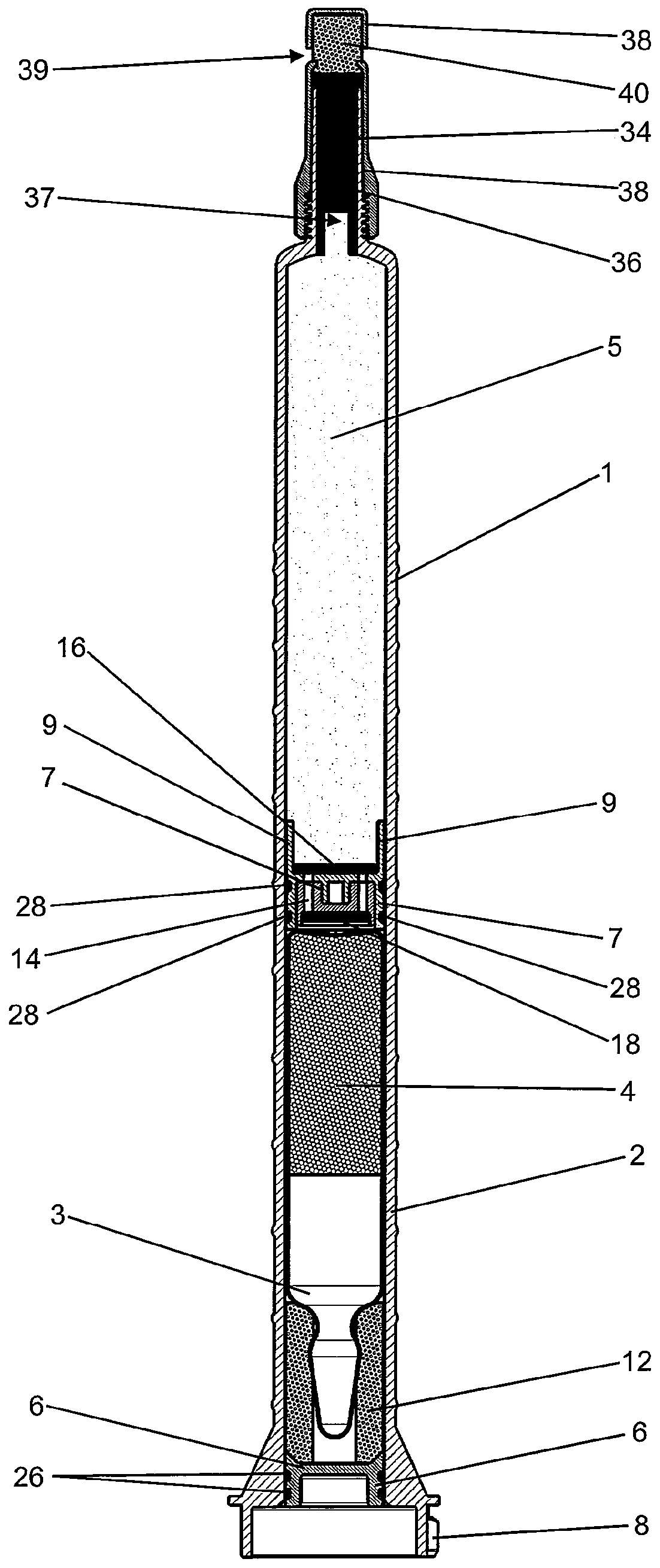

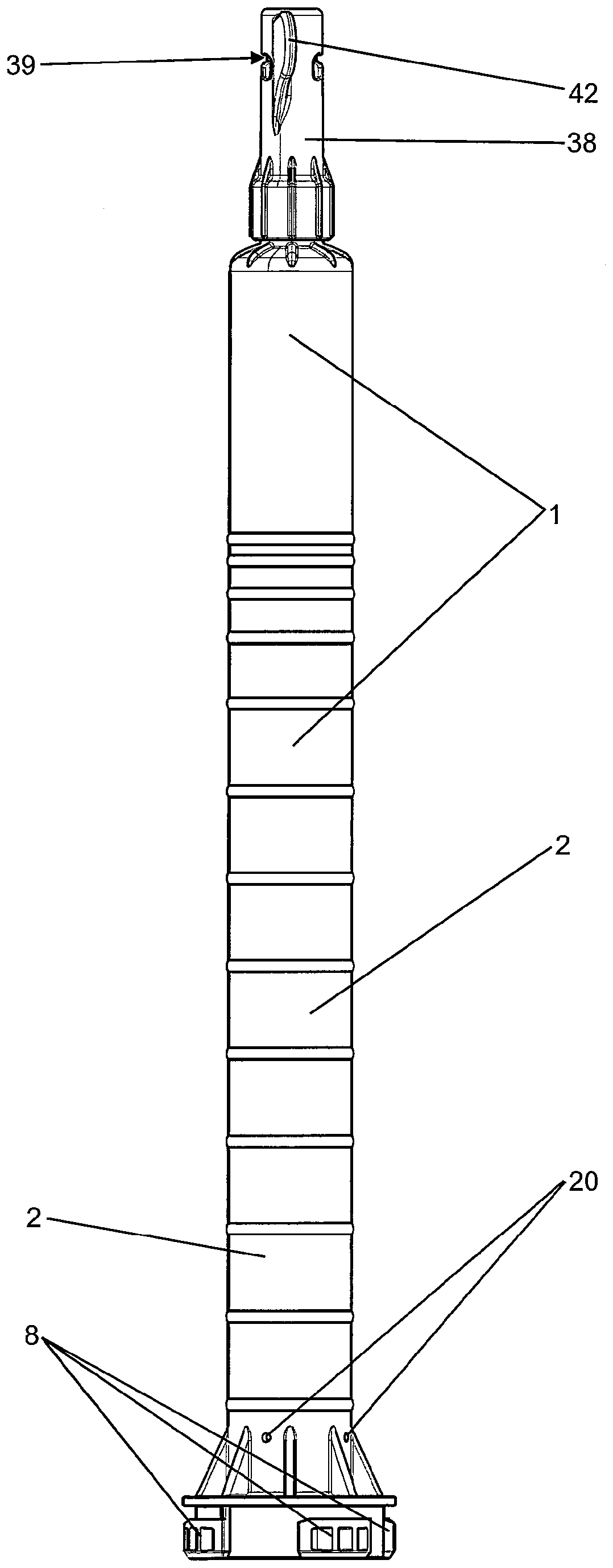

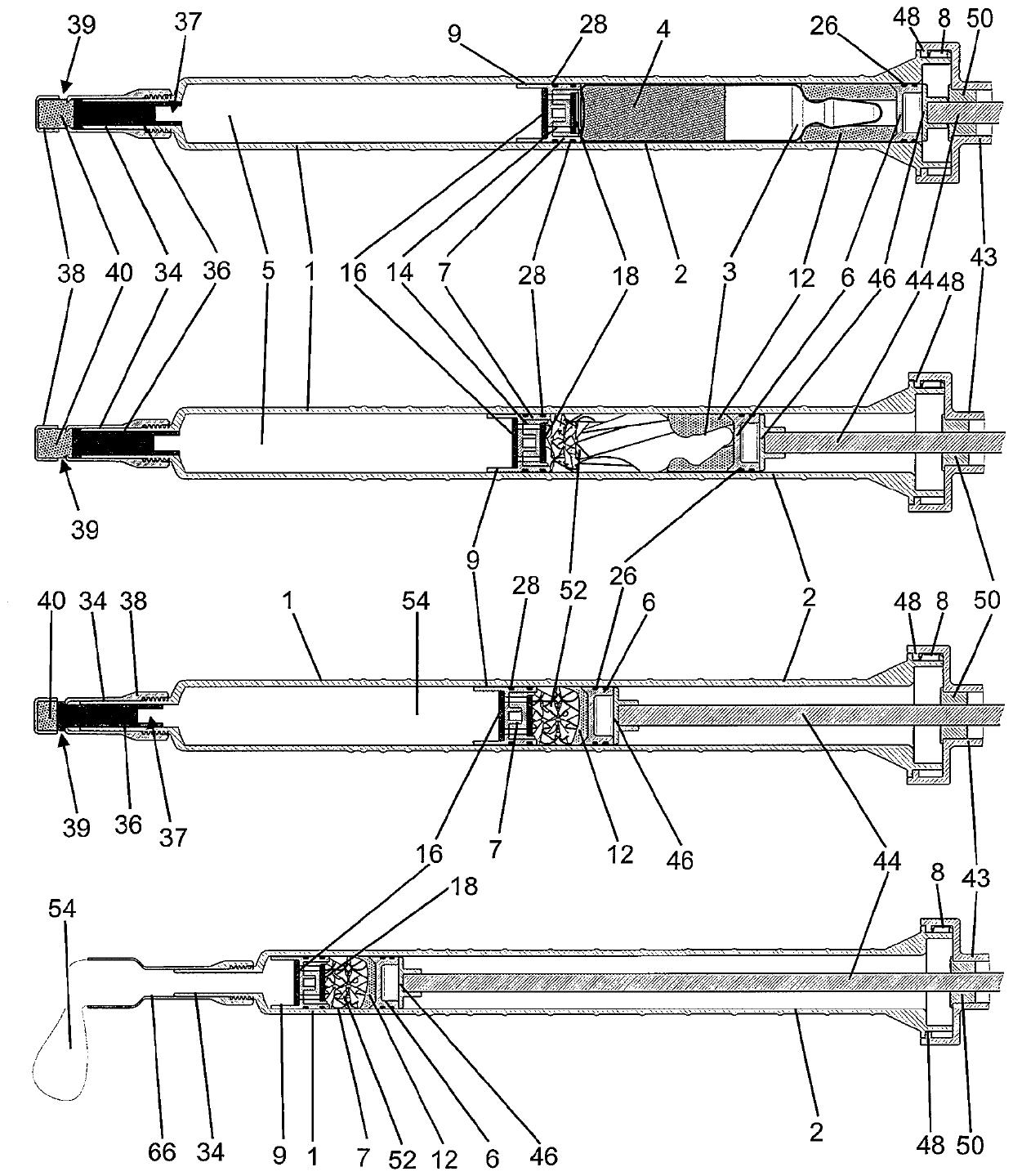

[0149] Figures 1 to 9 A diagram of a device according to the invention is shown. Figure 1-3 And 5 and 6 show various schematic overviews of exemplary devices according to the invention. Figure 4 with 7 - 9 shows a schematic cross-sectional view as a detail in the form of an enlarged detail through different regions of the device according to the invention.

[0150] The device according to the invention essentially comprises a plastic tubular container formed as a front ( figure 1 with 2 centered at the top, image 3 , 4 , 7-9 are on the left, Figure 5 center in the upper right, Image 6 A cartridge 1 having a cylindrical inner space in the lower left) part, and forming a holder 2 as a rear part for a glass ampoule 3 as a single liquid container. Instead of the glass ampoule 3 , a breakable plastic ampoule or, in the case of smaller modifications, a tearable film bag of metal-coated plastic can also be used instead of the glass ampoule 3 .

[0151] The rear of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com