Brush plating device

A brush plating and fixing device technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve problems affecting the uniformity of electroplating, workpiece up and down movement, unreliable positioning, etc., to achieve the guaranteed effect, reduce the number of reciprocating movements, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

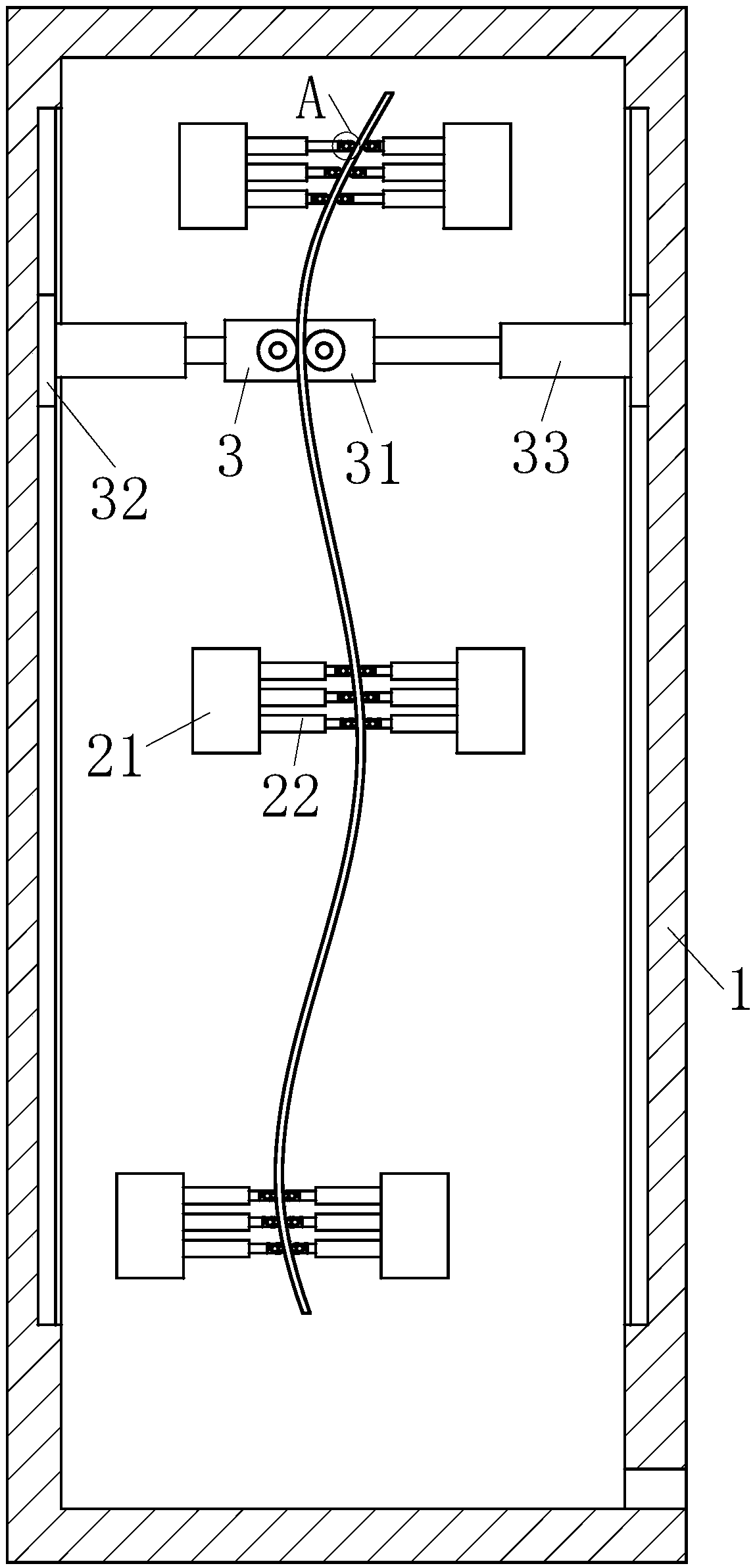

[0022] use Figure 1-Figure 4 A brush plating apparatus according to one embodiment of the present invention will be described below.

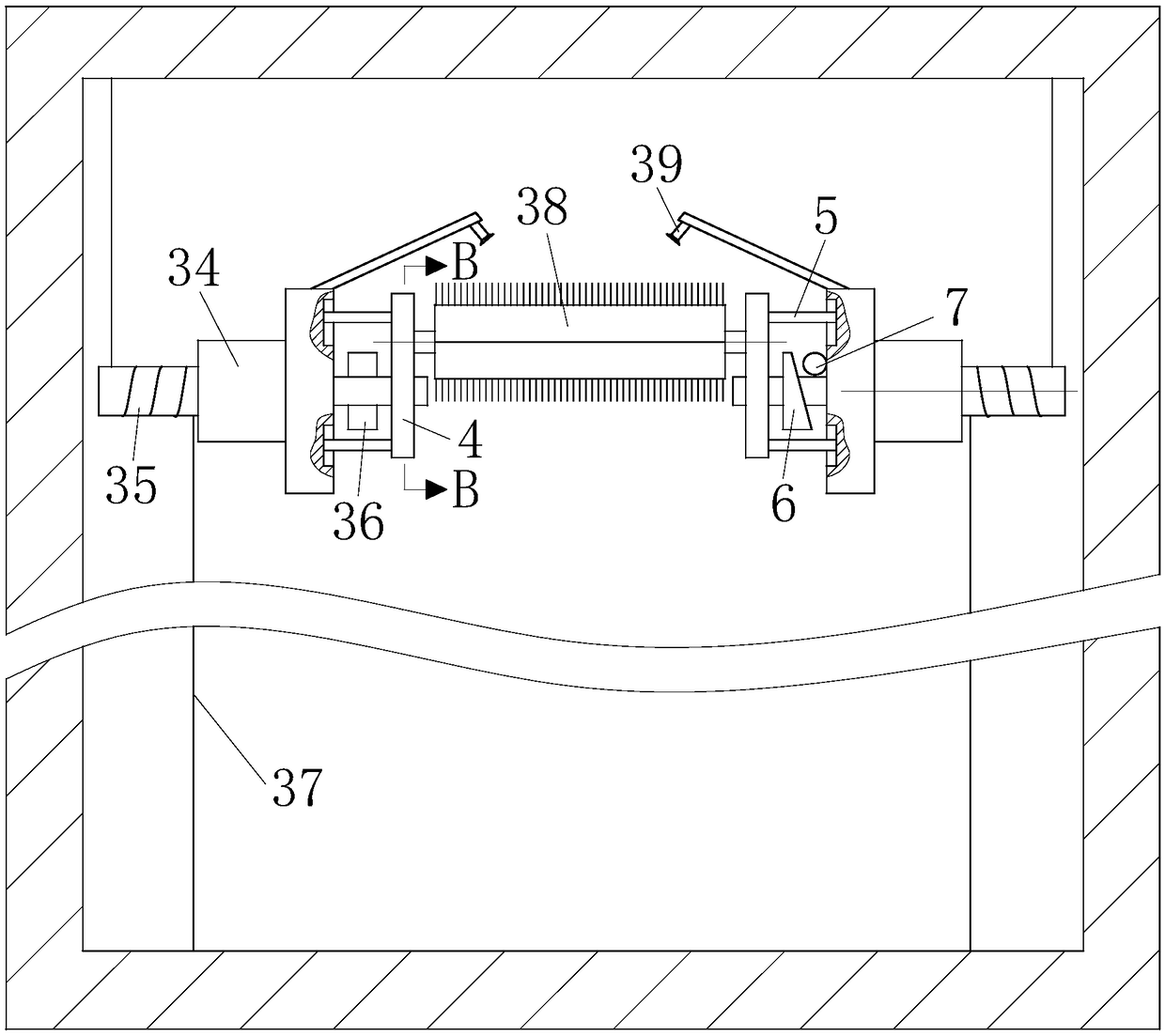

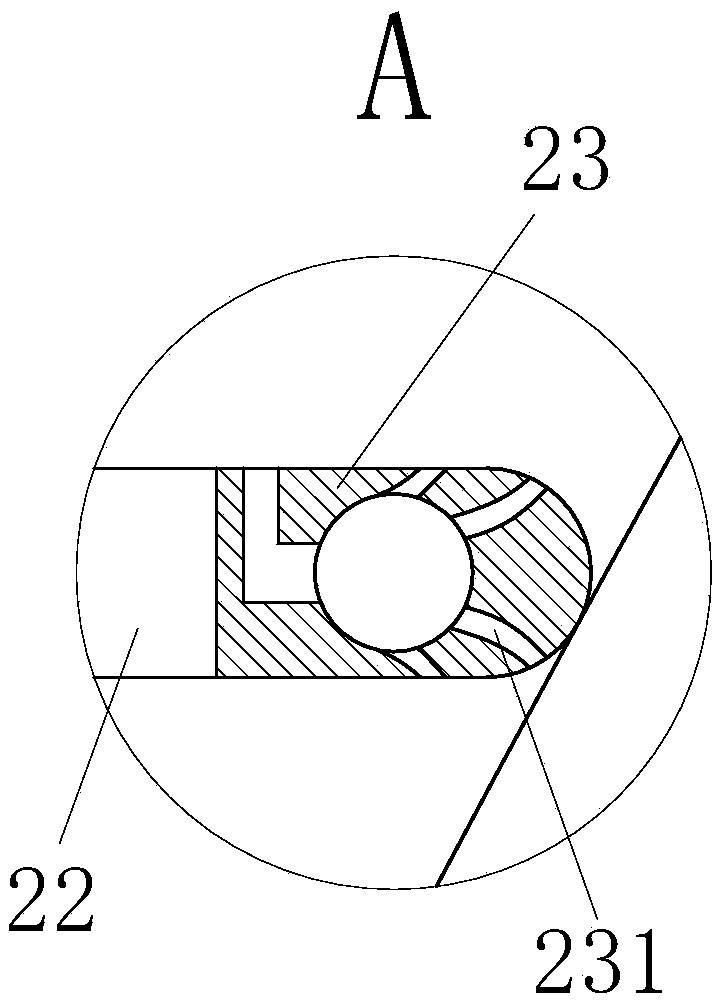

[0023] Such as figure 1 with figure 2 As shown, a brush plating device according to the present invention includes a box body 1, a fixing device 2 and a brushing device 3, and the fixing devices 2 are arranged symmetrically in the box body 1 in groups of two, and the box body 1 is provided with at least three groups along the vertical direction. The fixing device 2 is used to clamp the workpiece to facilitate the subsequent electroplating brushing operation; the brushing device 3 is located in the box body 1, and the brushing device 3 is used to divide the workpiece. Brush plating is carried out in the section, and the brush liquid is stored at the bottom of the box body 1; wherein,

[0024]Described brushing device 3 comprises base plate 31, sliding seat 32, telescopic rod one 33, double-headed motor 34, rotating shaft, lifting shaft 35, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com