A kind of preparation method of light and thin fabric with three warps and three wefts

A light and thin fabric technology, applied in textiles, fiber processing, textiles and papermaking, etc., can solve the problems of drop-off pieces, fine yarn counts, and warp yarn breakages, etc., and achieves low weaving process cost, good application prospects, and full feel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

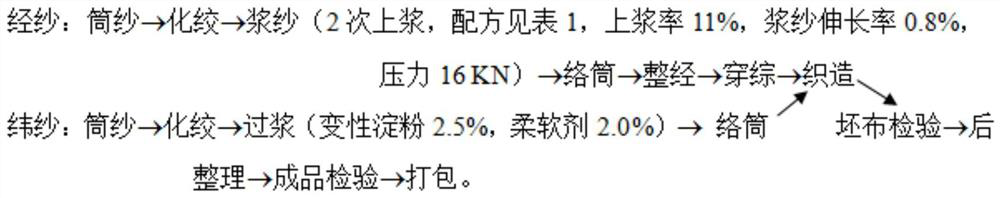

[0025] The spinning process such as figure 1 shown.

[0026] Table 1 warp yarn sizing formula (unit: %)

[0027] PVA modified starch softener the first time 2.5 0.55 0.30 the second time 1.5 0.50 1.50

[0028] Warp and weft: 100 s ×100 s PET white yarn / black yarn, warp and weft yarn density: 615×562 threads / cm; fabric tightness: warp direction 44.5%, weft direction 33.4%, total tightness 63.5%; fabric structure: plain weave (Minger); fabric width 150cm.

[0029] The warping control tension is 8% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It is driven by a frequency conversion motor...

Embodiment 2

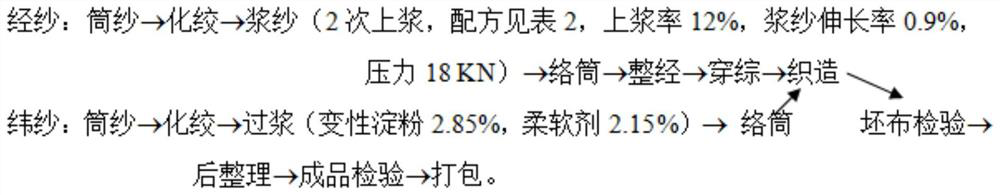

[0033] The spinning process such as figure 2 shown.

[0034] Table 2 warp yarn sizing formula (unit: %)

[0035] PVA modified starch softener the first time 2.7 0.58 0.35 the second time 1.8 0.60 1.7

[0036] Warp and weft: 80 s ×80 s PET white yarn / black yarn, warp and weft yarn density: 413×512 threads / cm; fabric tightness: warp direction 41.3%, weft direction 31.5%, total tightness 62.1%; fabric structure: plain weave (Minger); fabric width 155cm.

[0037] The warping control tension is 9% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It is driven by a frequency conversion motor to...

Embodiment 3

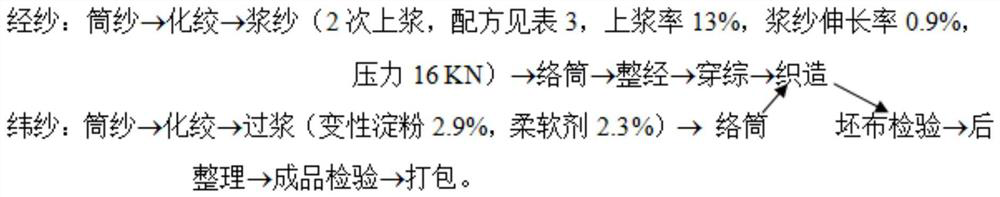

[0041] The spinning process such as image 3 shown.

[0042] Table 3 warp yarn sizing formula (unit: %)

[0043] PVA modified starch softener the first time 2.65 0.60 0.40 the second time 2.0 0.75 1.80

[0044] Warp and weft: 120 s ×120 s PET white yarn / blue yarn, warp and weft yarn density: 764×684 threads / cm; fabric tightness: warp direction 47.5%, weft direction 36.4%, total tightness 62.1%; fabric structure: plain weave (Minger); fabric door The width is 150cm.

[0045]The warping control tension is 8.5% of the single yarn strength, the tension difference between single yarns is not more than 2cN, and the unevenness is less than 1.5%. A section warping machine is adopted with a machine speed of 450r / min. The intermittent warping reciprocating creel is adopted, and the tension disc adopts a double-disc structure. The pressure is controlled by the angle of the disc and the weight of the tension disc. It is driven by a frequency conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com