Quickly-spliced sunlight room

A rapid splicing and sunshine room technology, applied in the field of sunshine rooms, can solve the problems of hidden safety hazards, complex installation of sunshine rooms, easy rust and corrosion of screws, etc., and achieve the effect of good structural stability, high assembly efficiency and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

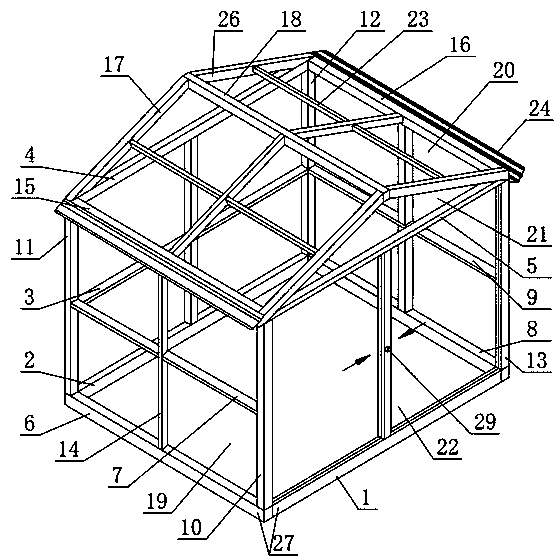

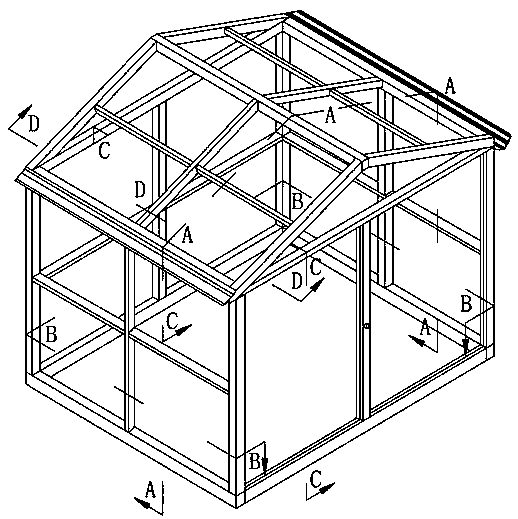

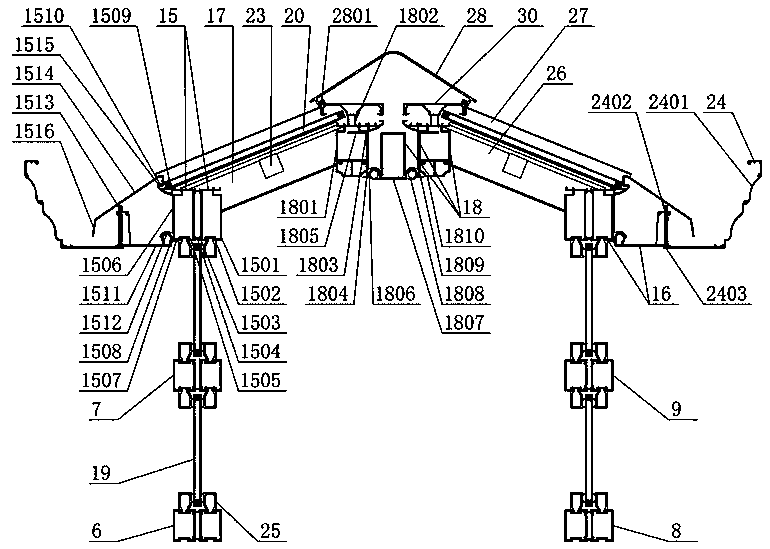

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] refer to Figure 1-21, a quick splicing sun room described in this specific embodiment, including beam column assembly A1, beam column assembly B2, beam column assembly C3, beam column assembly D4, beam column assembly E5, longitudinal beam column assembly A6, longitudinal beam column assembly Component B7, longitudinal beam column component C8, longitudinal beam column component D9, beam column component A10, beam column component B11, beam column component C12, beam column component D13, beam column component E14, side beam component A15, side beam component B16, The main beam A17, the beam ridge assembly 18 and the main beam B26, the beam column assembly A1, the longitudinal beam column assembly A6, the beam column assembly B2, and the longitudinal beam column assembly C8 are fixedly connected from end to end to form a rectangular frame 31, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com