Automatic suction and discharge control system for oilfield mud cleaning

An emission control system and mud technology, applied in the drilling automatic control system, engine control, machine/engine, etc., can solve the inefficiency of the oil field mud suction and discharge operation process, the inability to continuously alternate operation, labor and time-consuming, etc. Problems, achieve the effect of reducing the labor load of workers, saving time consumption, and saving lifting and dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

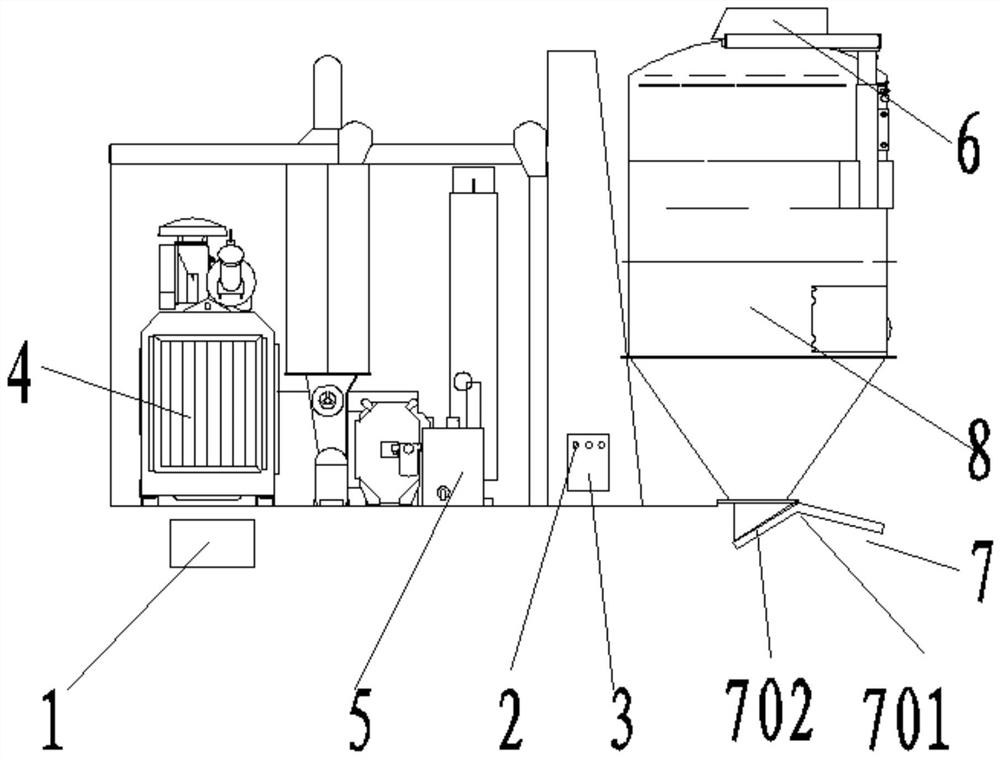

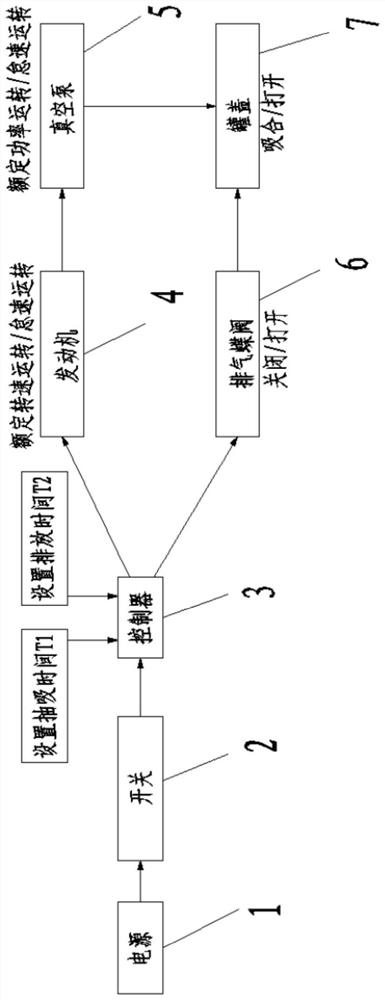

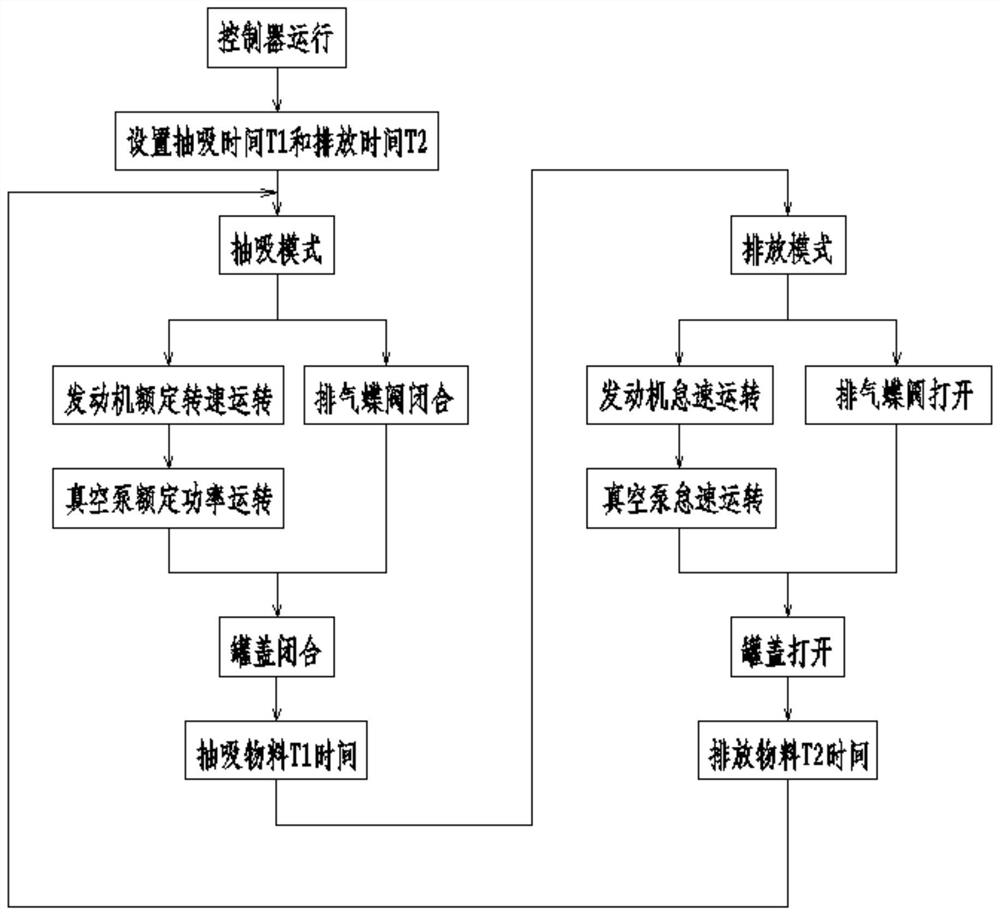

[0031] Attached below Figure 1-7 Specific examples of the present invention are described.

[0032] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The following embodiments are only some of the embodiments of the present invention, but not all of them. The implementation of the control circuit in the following embodiments is a conventional control method unless otherwise specified. The components used in the following examples are commercially available unless otherwise specified.

[0033] In the present invention, unless otherwise clearly specified and limited, in the absence of a contrary description, the orientation words included in the terms such as "up, down, left, right, inside, outside, vertical, horizontal" are only It represents the orientation of the term in conventional use, or for the convenience of describing the present invention and simplification of description, or is a common name...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com