Structure for fixing steam turbine flow guide plate for ship

A steam turbine and deflector technology, applied in the field of ship power, can solve the problems of difficult casting, poor safety and reliability, difficult inspection and maintenance, etc., and achieve the effects of simplifying the manufacturing structure, convenient maintenance, and improving inspectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

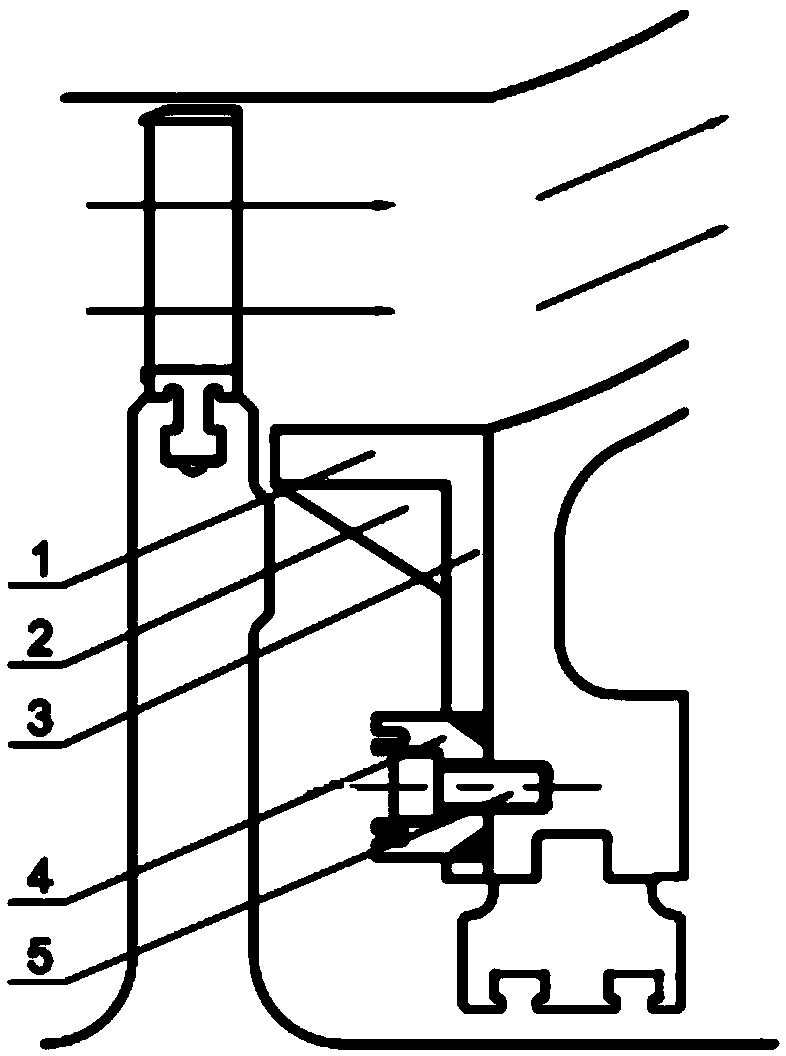

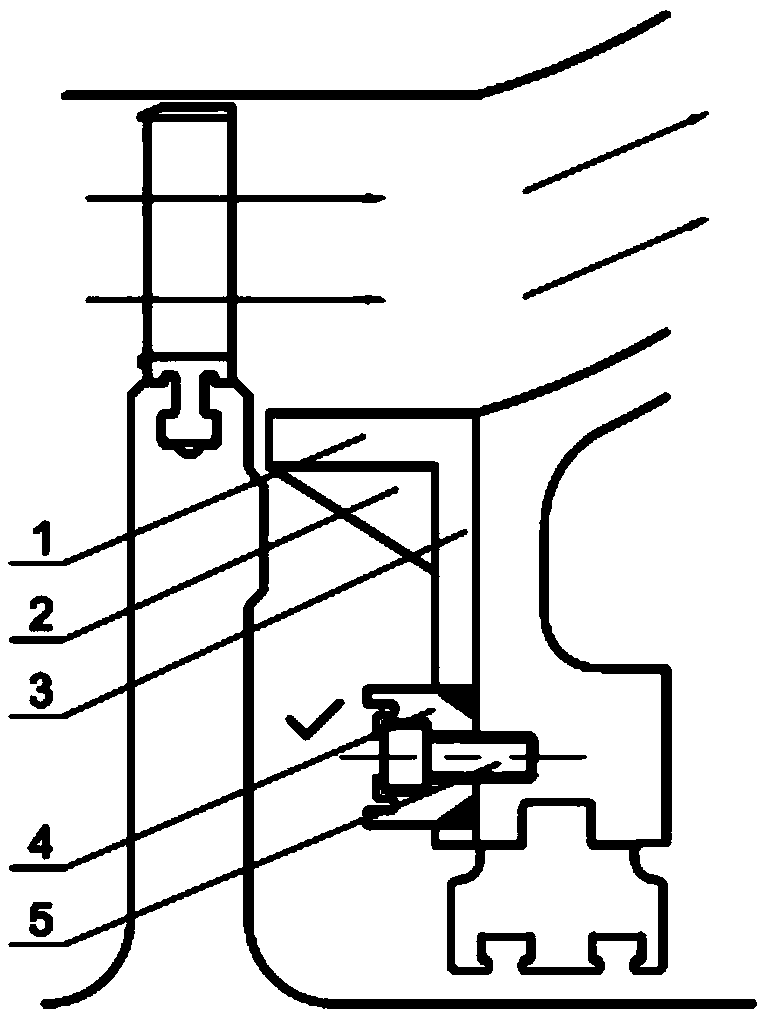

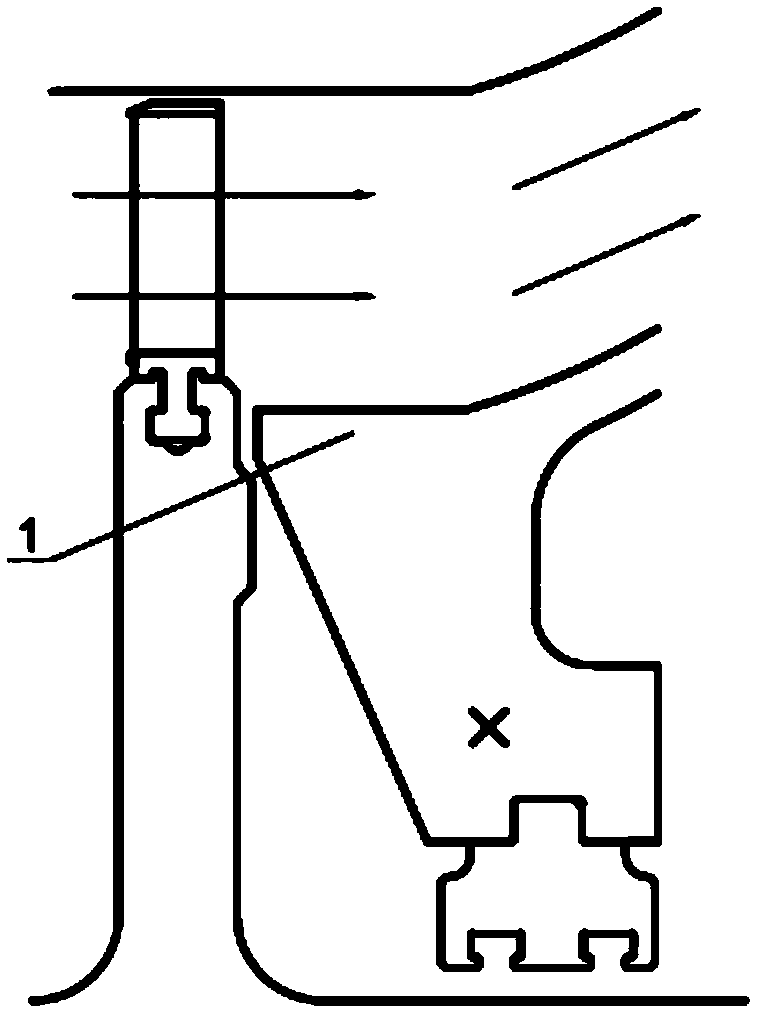

[0018] Specific implementation mode one: as Figure 1~2 As shown, the fixed marine steam turbine deflector structure of the present embodiment includes a deflector sleeve 1, a fixed plate 3, a plurality of ribs 2 and a plurality of hexagon socket screws 5, and the steam turbine deflector structure also includes a plurality of anti The loose gasket block 4, the guide sleeve 1 and the fixed plate 3 are fixed as a whole, the fixed plate 3 is located on one end of the guide sleeve 1, the rib plate 2 is a right-angled triangular plate, and two of each rib plate 2 One of the right-angled sides is fixed to the guide sleeve 1, and the other of the two right-angled sides of each rib 2 is fixed to the fixed plate 3. The plurality of ribs 2 are arranged in parallel and evenly distributed, and the inner hexagon The quantity of the screw 5 is consistent with the quantity of the anti-loosening washer block 4, and the fixed plate 3 is fixed on the cylinder by the hexagon socket head cap scre...

specific Embodiment approach 2

[0034] Specific implementation mode two: as figure 1 and figure 2 As shown, the flow guide sleeve 1 of this embodiment is composed of an upper flow guide sleeve and a lower flow guide sleeve, and the upper flow guide sleeve and the lower flow guide sleeve are symmetrically arranged up and down. This design ensures the vertical symmetrical structure of the steam flow channel, which reduces the aerodynamic loss of the steam in the flow channel. At the same time, the vertical symmetrical structure of the guide sleeve also simplifies the production and installation work, and is convenient for disassembly and maintenance. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: as figure 1 and figure 2As shown, the number of anti-loosening washer blocks 4 in this embodiment is an even number, and the number of anti-loosening washer blocks 4 ranges from 6 to 10. The upper guide sleeve and the lower guide sleeve pass through the same number of anti-loosen washer blocks. 4 and the same number of hexagon socket head screws 5 are fixed on the cylinder. With such a design, the anti-loosening washer block 4 can effectively prevent the screws on the deflector from loosening and falling off. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com