Roasting flue gas treatment method for carbon anode

A flue gas treatment, carbon anode technology, applied in the direction of combustion method, combustion product treatment, waste heat treatment, etc., can solve the problems of unsatisfactory treatment of asphalt tar, high energy consumption, etc., to reduce emissions, reduce energy consumption, and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

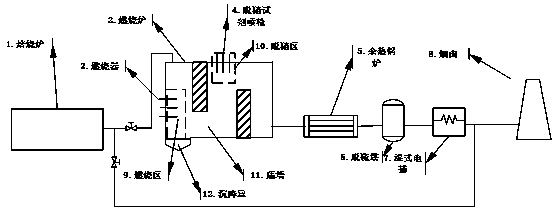

[0027] Example 1: The flue gas from the roaster passes through the combustion furnace (denitration agent: urea solution: sodium borohydride: ethanol = 8:1:3), waste heat boiler, desulfurization tower (desulfurization agent: milk of lime: dodecylsulfonic acid Sodium: citric acid = 8:2:3), wet electric capture, exhausted into the atmosphere through the chimney. The combustion furnace 2 is mainly composed of four parts: a combustion zone 9 , a denitrification zone 10 , a partition wall 11 and a settling chamber 12 . The fuel in the flue gas treatment process is mainly natural gas or heavy oil. In addition, a small amount of waste tar, petroleum coke, residual electrode, dust collection powder, waste cathode, coal, coal-based coke powder and other one or more mixtures can also be added. . The amount of fuel injected depends on the temperature of the denitrification zone. Pollutant components in the final exhaust flue gas: NOx content 40mg / Nm3, SO2 content 29 mg / Nm3, fluoride conte...

Example Embodiment

[0028] Example 2: The flue gas from the roaster passes through the combustion furnace (denitration agent: urea solution: sodium borohydride: ethanol = 6:2:4), waste heat boiler, desulfurization tower (desulfurization agent: milk of lime: dodecylsulfonic acid Sodium: citric acid = 9:3:3), wet electric capture, exhausted into the atmosphere through the chimney. The combustion furnace 2 is mainly composed of four parts: a combustion zone 9 , a denitrification zone 10 , a partition wall 11 and a settling chamber 12 . The fuel in the flue gas treatment process is mainly natural gas or heavy oil. In addition, a small amount of waste tar, petroleum coke, residual electrode, dust collection powder, waste cathode, coal, coal-based coke powder and other one or more mixtures can also be added. . The amount of fuel injected depends on the temperature of the denitrification zone. Pollutant components in exhaust flue gas: NOx content 33mg / Nm3, SO2 content 23 mg / Nm3, fluoride content 0.2 m...

Example Embodiment

[0029] Example 3: The flue gas from the roasting furnace passes through the combustion furnace (denitration agent: urea solution: sodium borohydride: ethanol = 1:4:4), waste heat boiler, desulfurization tower (desulfurization agent: milk of lime: dodecylsulfonic acid Sodium: citric acid = 10:3:3), after wet electric capture, it is discharged into the atmosphere through the chimney. The combustion furnace 2 is mainly composed of four parts: a combustion zone 9 , a denitrification zone 10 , a partition wall 11 and a settling chamber 12 . The fuel in the flue gas treatment process is mainly natural gas or heavy oil. In addition, a small amount of waste tar, petroleum coke, residual electrode, dust collection powder, waste cathode, coal, coal-based coke powder and other one or more mixtures can also be added. . The amount of fuel injected depends on the temperature of the denitrification zone. Pollutant components in exhaust flue gas: NOx content 15mg / Nm3, SO2 content 16mg / Nm3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com