Differential structure light illumination microscopic measurement method for three-dimensional dynamic real-time measurement of micro-nano structure

A structured light illumination and real-time measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex signal processing, large errors, low efficiency, etc., and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in combination with specific examples and with reference to the accompanying drawings.

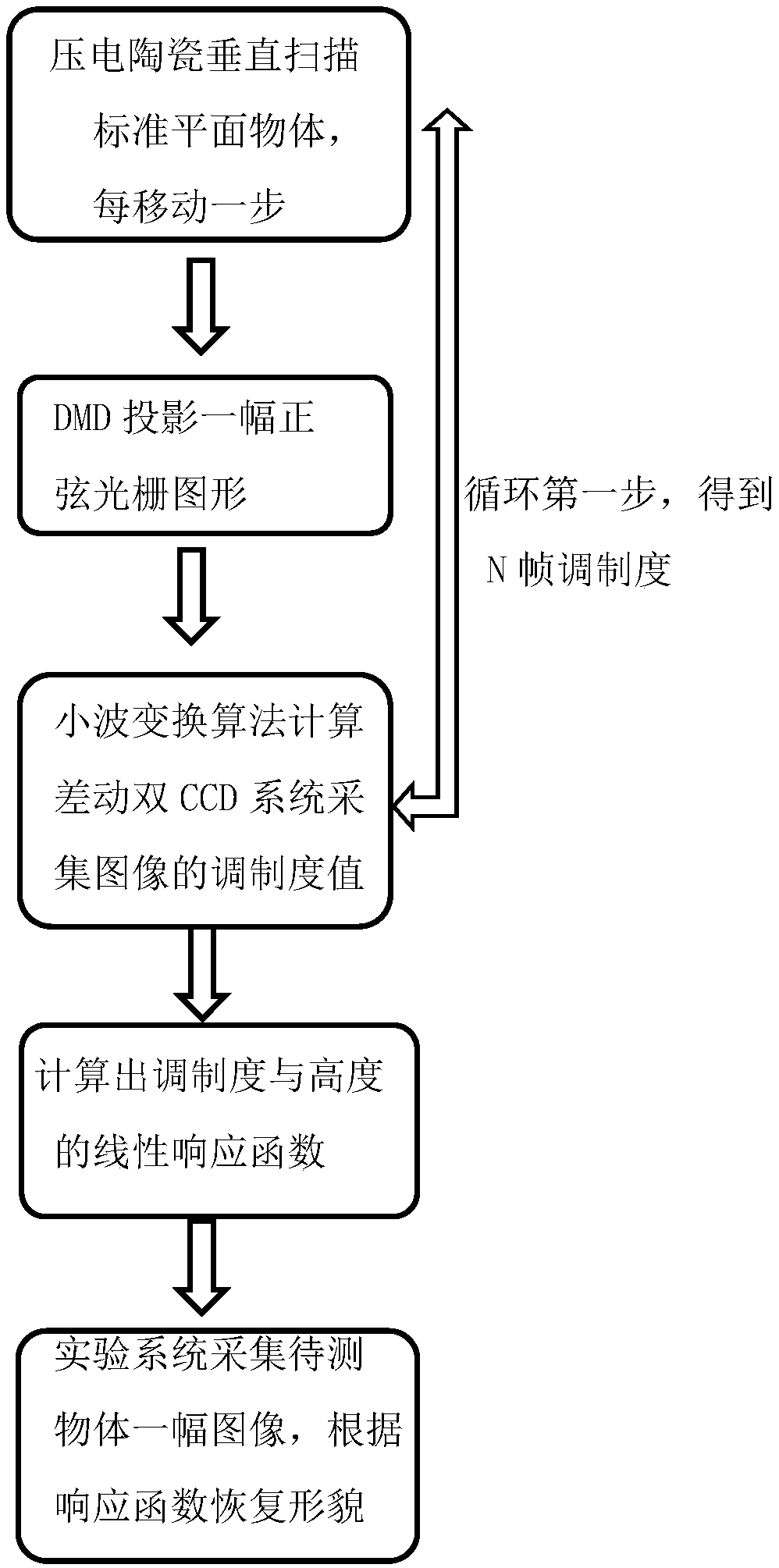

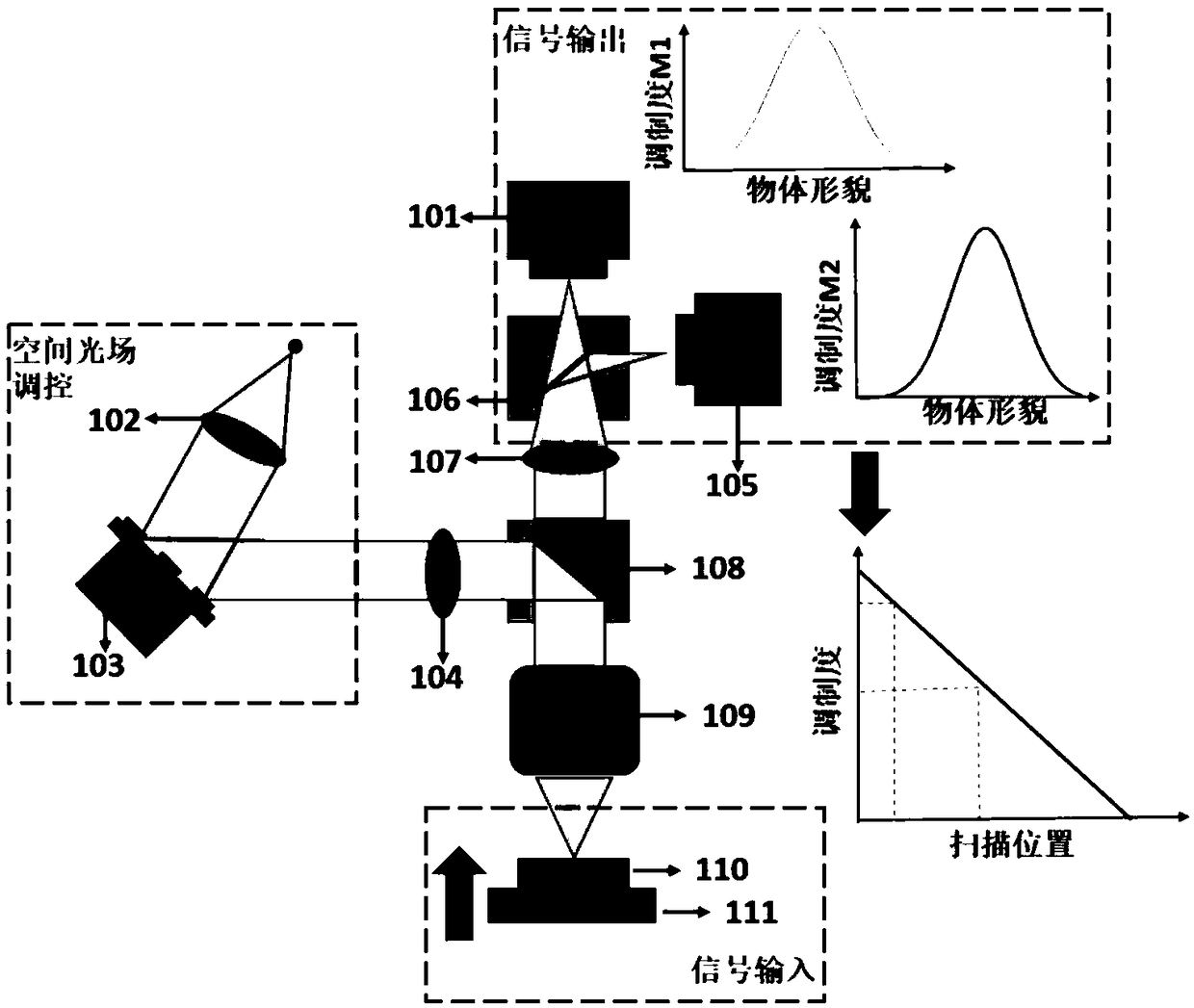

[0026] Such as Figure 1-2 As shown, a differential structured illumination micro-measurement method for three-dimensional dynamic measurement of micro-nano structure, the method steps include:

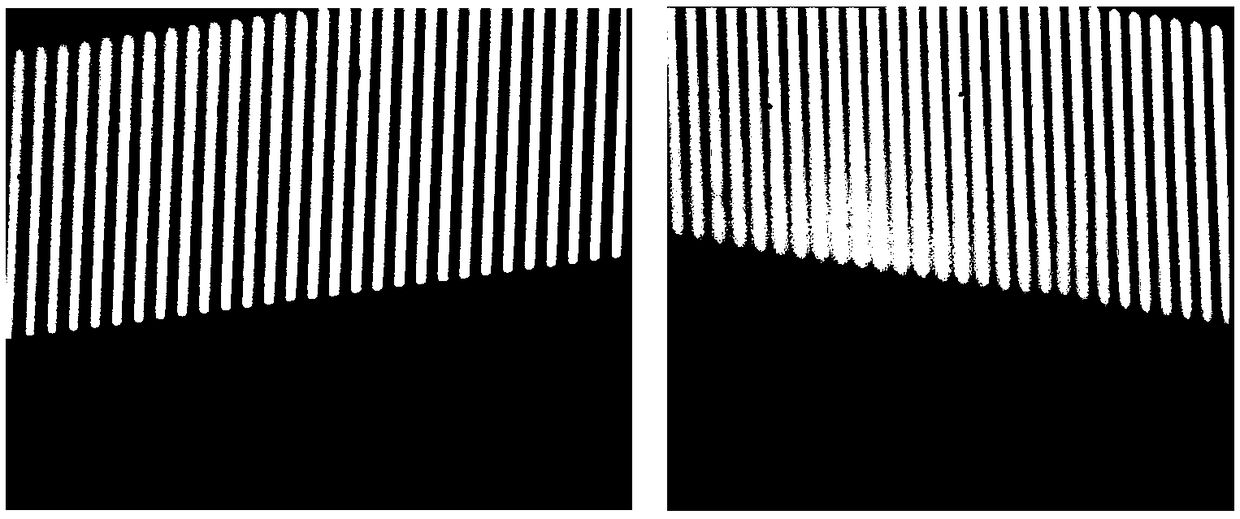

[0027] Step S1: Use the host computer program to control the piezoelectric ceramic micro-step to vertically scan the standard plane object, scan each step, use the DMD to project the sinusoidal grating fringe, use the differential dual CCD system to collect the deformed fringe pattern, and then convert it into a digital signal and store it in the computer.

[0028] Step S2: For each scan, for the fringe patterns collected by the first CCD 101 and the second CCD 105, use the wavelet transform algorithm to calculate the modulation va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com