A Fault Diagnosis Method for Oil Pump Bearings

A fault diagnosis and oil pump technology, applied in the testing of machines/structural components, mechanical components, instruments, etc., can solve problems such as uncertainty, high risk of oil pump fault identification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with embodiment.

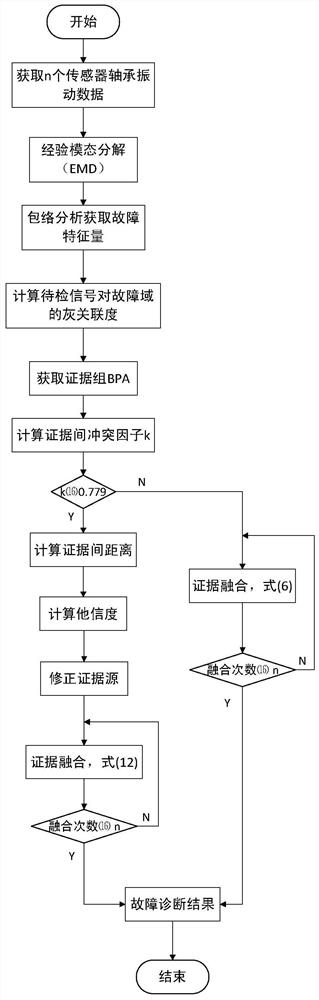

[0072] A method for diagnosing bearing faults of an oil pump uses multiple bearing acceleration sensors to collect vibration signals of the bearings, and diagnoses faults based on the processing of the vibration signals. The new oil pump fault diagnosis method mainly includes three parts: a data collection processing step, a basic probability assignment (Basic Probability Assignment, BPA) step, and a evidence reasoning synthesis fault identification step.

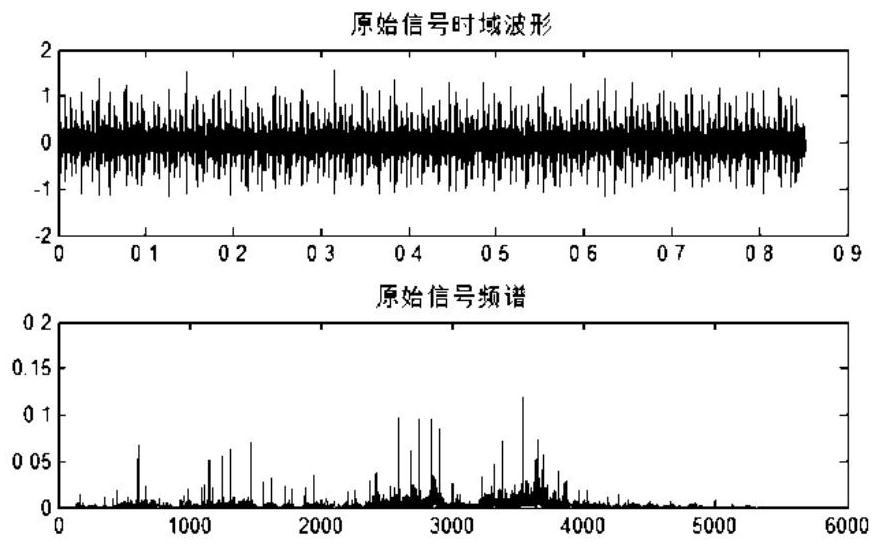

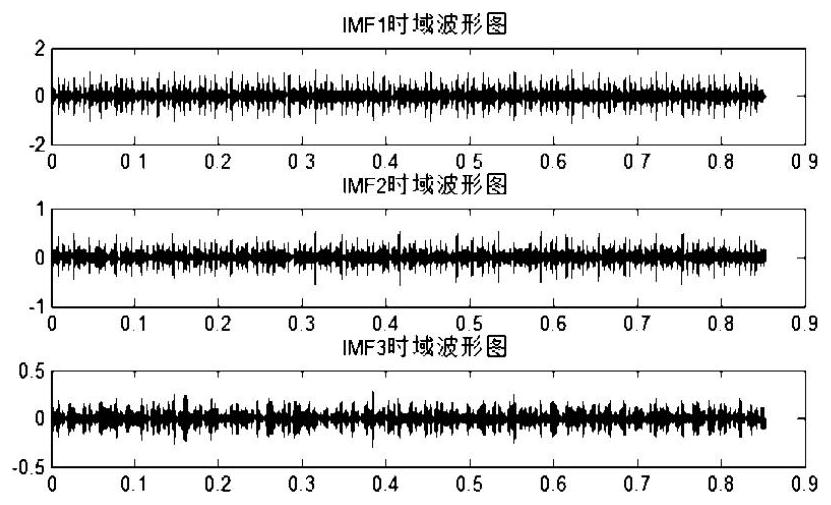

[0073] Take a 1.5KW motor, and the tested bearing supports the motor shaft as an example. A single-point fault is arranged on the bearing using EDM technology, and the fault diameter is 0.1778mm. The vibration signal is collected by an acceleration sensor. The vibration signal is collected by a 16-channel DAT recorder and processed in the MATLAB environment later. The sampling frequency is 12000Hz, and the bearing speed is 1772r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com