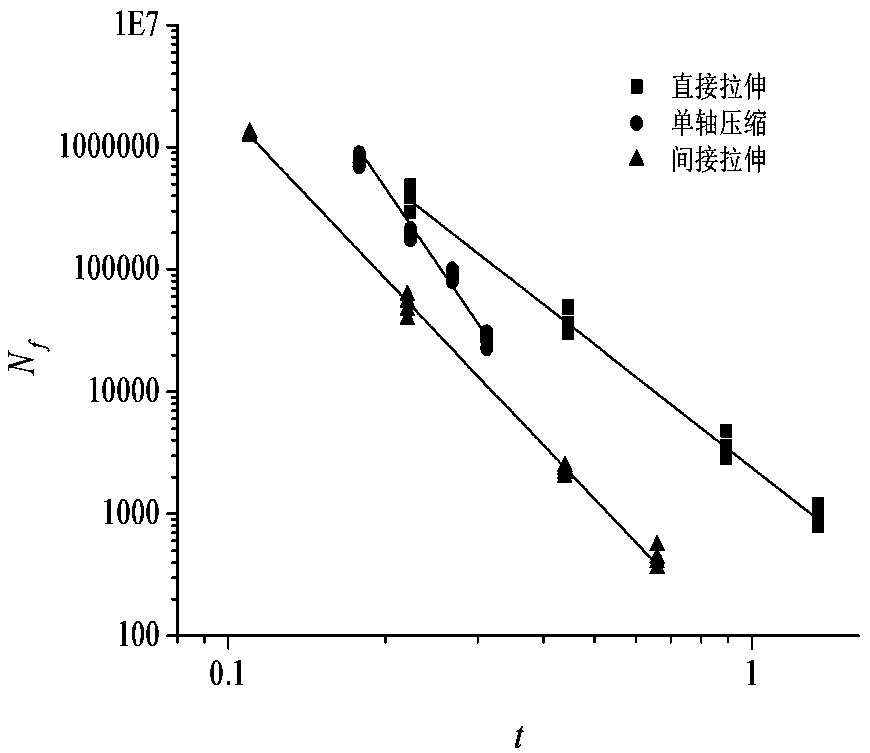

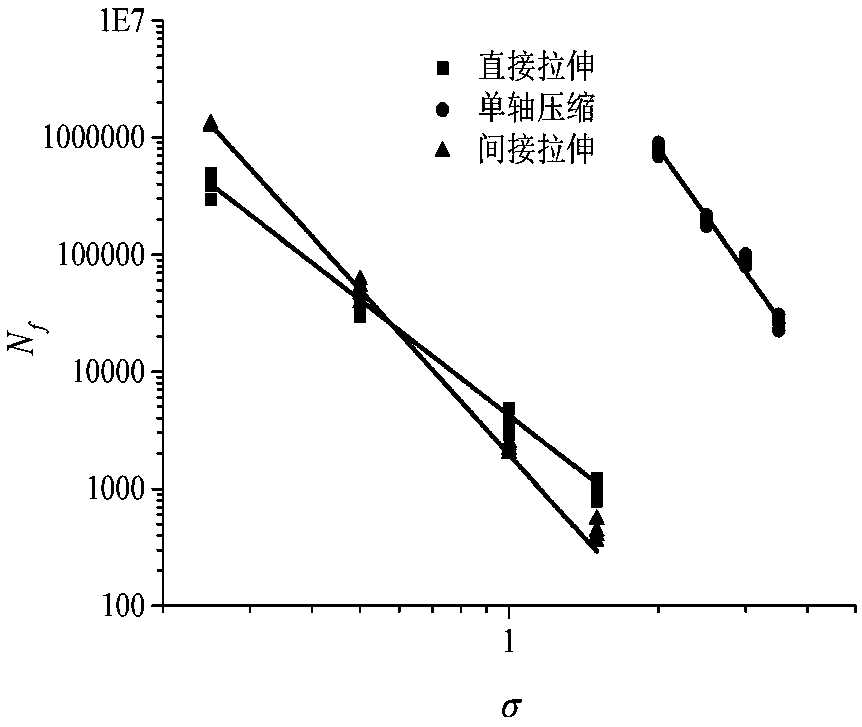

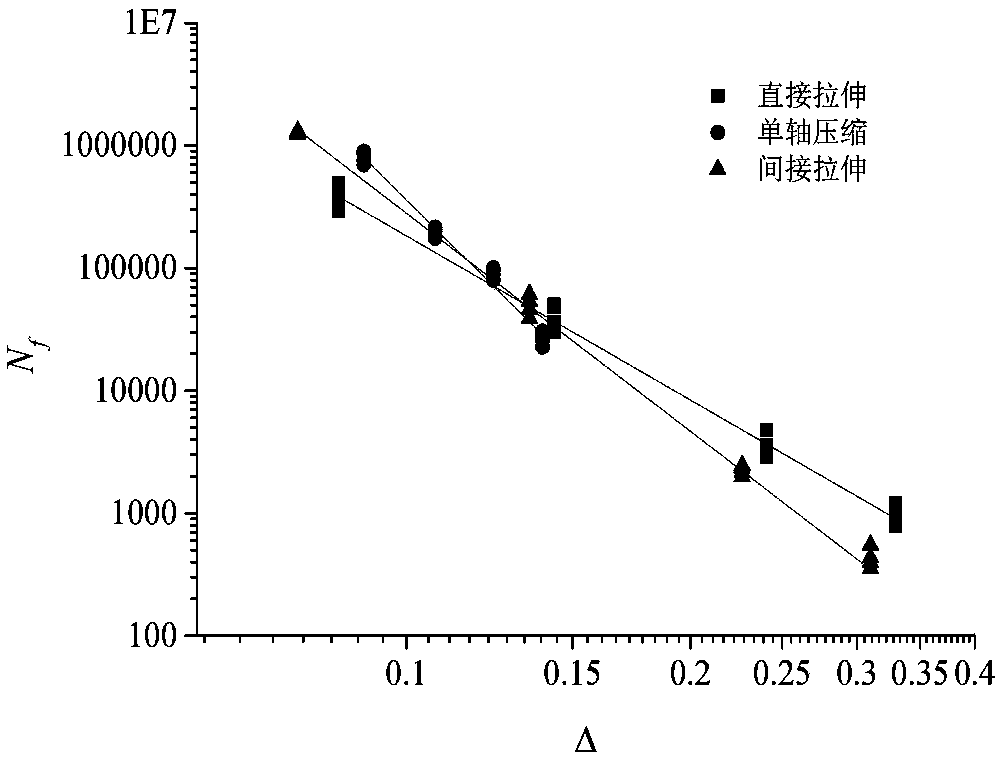

Normalization method for fatigue characteristics of asphalt mixture under different stress states

A technology of asphalt mixture and stress state, which is applied in the direction of using stable tension/compression to test the strength of materials, and can solve problems such as non-conformity and constant tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] 1) Direct tensile fatigue test method

[0060] The mineral material is screened layer by layer, and the weighed mineral material is preheated in the oven for 4 hours to fully dry the mineral material. Each time, add mineral material or asphalt to the mixing pot and stir for 90 seconds to make the aggregate Stir well. Using the vibrating compactor, it is convenient to adjust parameters such as vibration mode, compaction height and compaction rate. The size of the roll-formed test panel is 400mm×300mm×50mm; it is then cut into beam-type test pieces of 250×50×50mm for direct tensile strength and fatigue tests;

[0061] The test adopts the MTS-Landmark material testing system. The direct tensile test piece is kept at a constant temperature of 15°C in an incubator for 4-5 hours. The operating program is compiled through the built-in MPT and the applied load and acquisition parameters are set. The force of each loading cycle It is automatically measured by the data acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com