Multi-sample rapid bending fatigue experimental device

A fatigue test, multi-sample technology, applied in the direction of using a stable bending force to test the strength of materials, can solve the problems of complex use and maintenance procedures, difficult to enter the laboratory, excessive volume, etc., to improve the experimental efficiency, suitable for Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

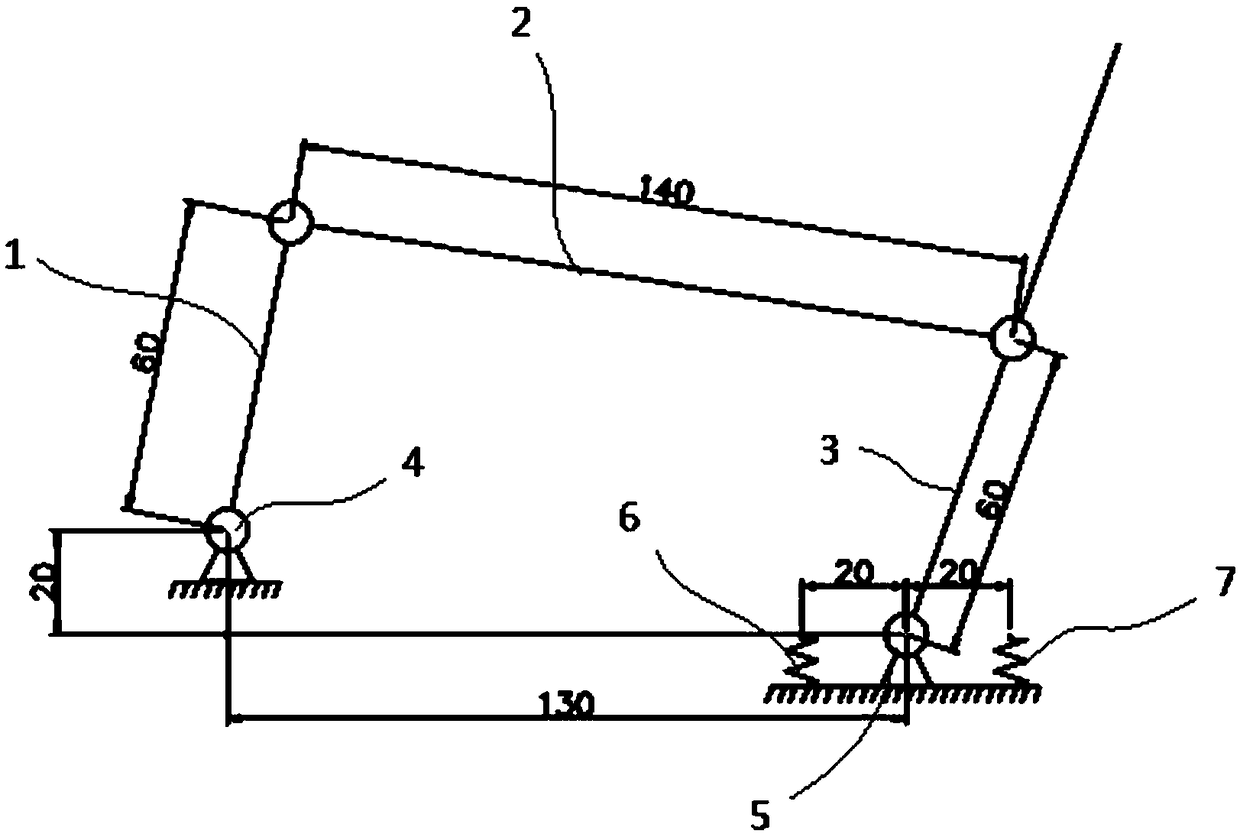

[0022] Such as figure 1 shown. The invention discloses a multi-sample rapid bending fatigue test device, which comprises a crank rocker mechanism installed on a base and an energy storage component at a dead point position;

[0023] The crank-rocker mechanism includes: a crank 1, a connecting rod 2, a rocker 3, a first fulcrum 4, and a second fulcrum 5; one end of the crank 1 is hinged to the first fulcrum 4, and the other end of the crank 1 passes through the shaft One end of the connecting rod 2 is hinged, the other end of the connecting rod 2 is hinged to the middle part of the rocker 3 through the rotating shaft, and the lower end of the rocker 3 is hinged with the second fulcrum 5;

[0024] The mechanical energy storage assembly at the dead point is arranged on both sides of the second fulcrum 5, and when the rocker 3 rotates to the end region of the rotatable stroke, the potential energy of the mechanical energy storage assembly at the dead point is converted into the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com