A control method and system based on circuit board automatic placement and insertion process

A control method and circuit board technology, applied in general control systems, control/regulation systems, electrical program control, etc., can solve problems such as time-consuming uncertainty, difficulty in meeting rapid modeling requirements, and data independence/splitting, etc. The effect of rapid modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0068] refer to Figure 1-6 , the present invention provides a control method based on circuit board automatic sticking and inserting process, which comprises the following steps:

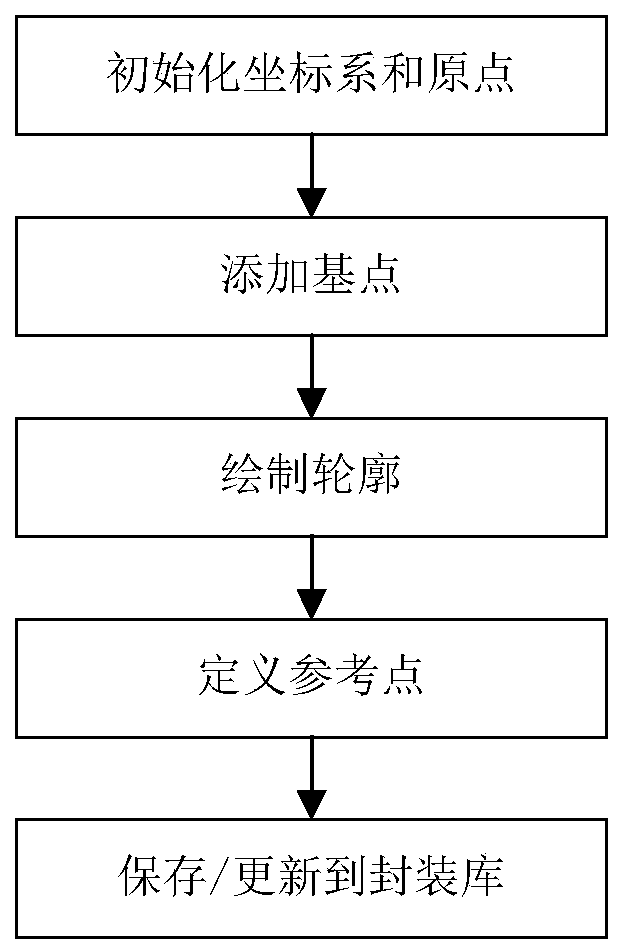

[0069] The system receives the material size information input by the user, establishes the material package, and realizes the visualization of material graphics / patterns;

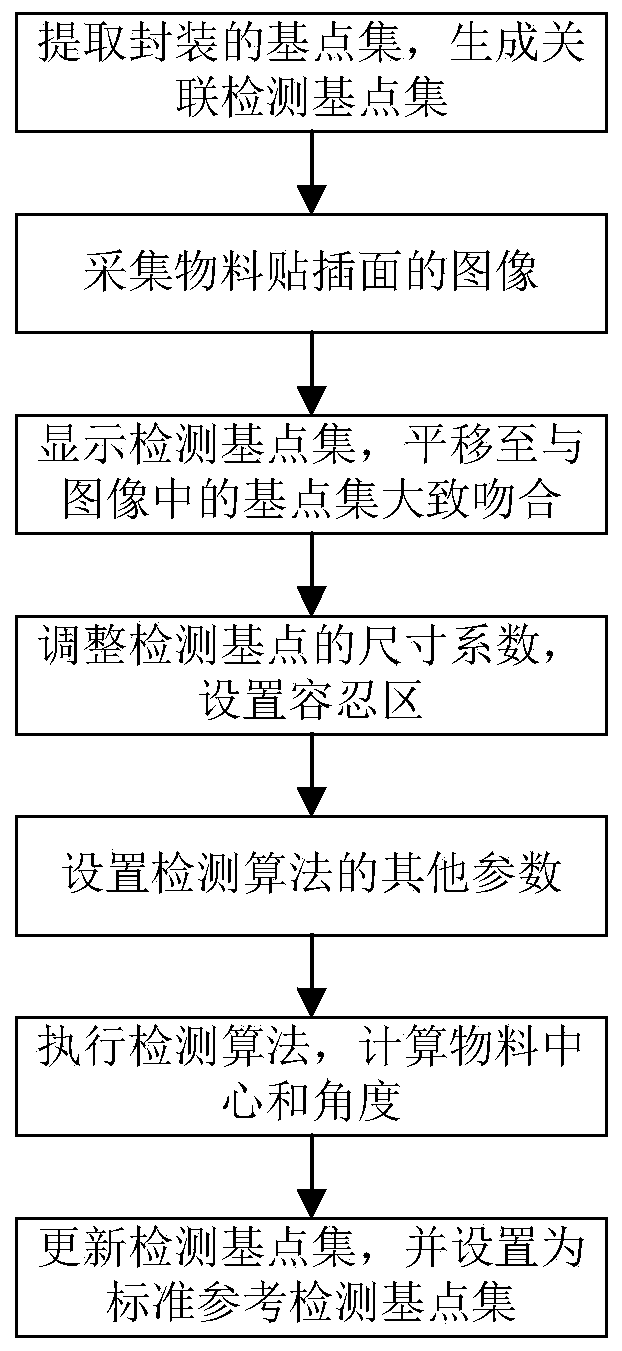

[0070] The system creates / modifies image algorithms to realize rapid modeling of material detection algorithms;

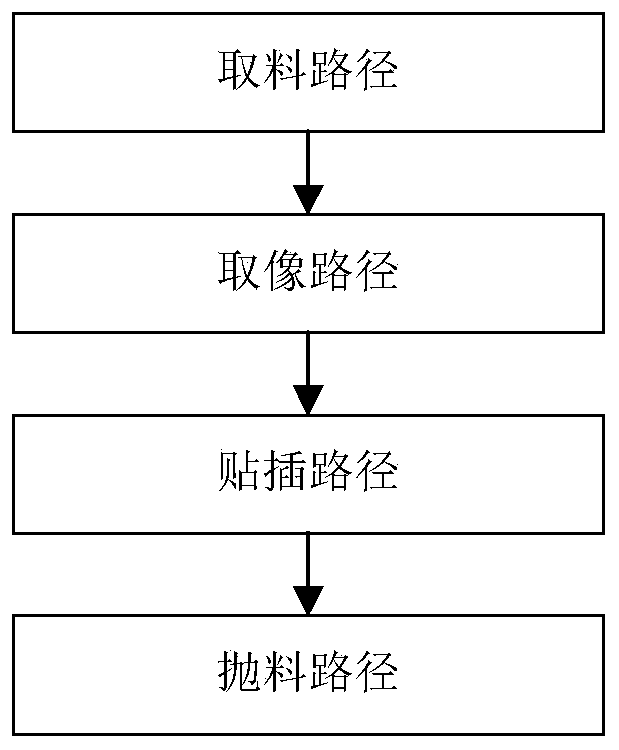

[0071] The system creates / modifies the material motion path set, which is used for motion control during the material insertion process;

[0072] The system creates / modifies the material data structure unit, and comprehensively describes various attributes of the material in the placement cycle through the data structure;

[0073] Based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com