A parameterized modeling method of laminated composite plate imitating mother-of-pearl

A composite board and imitation pearl technology, applied in the field of simulation analysis of mechanical properties of bionic composite materials, can solve the problems of time-consuming modeling process, heavy manual workload, cumbersome modeling process, etc., to reduce repetitive modeling work, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to more clearly demonstrate the purpose, technical solutions and advantages of the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

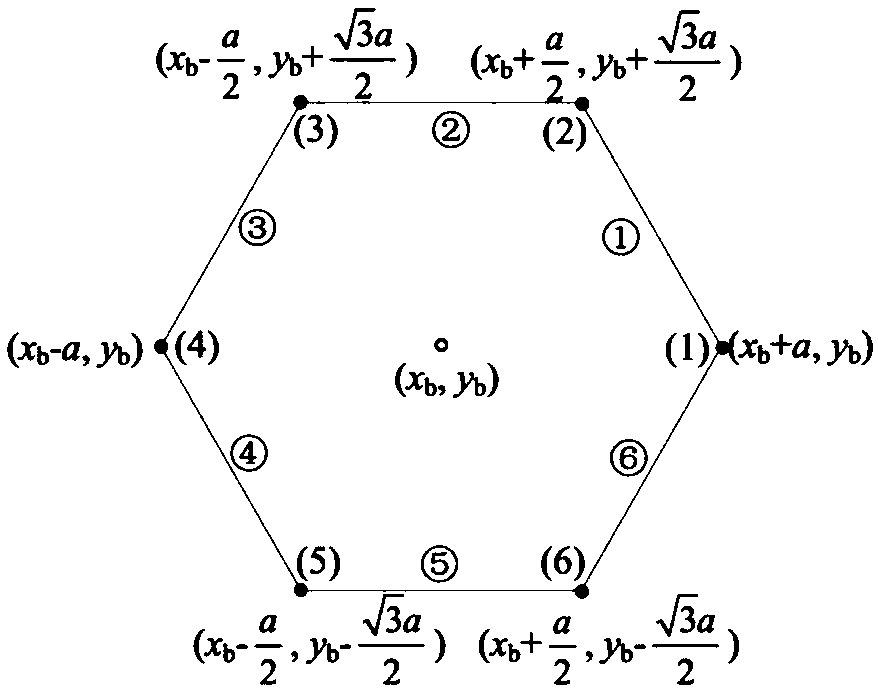

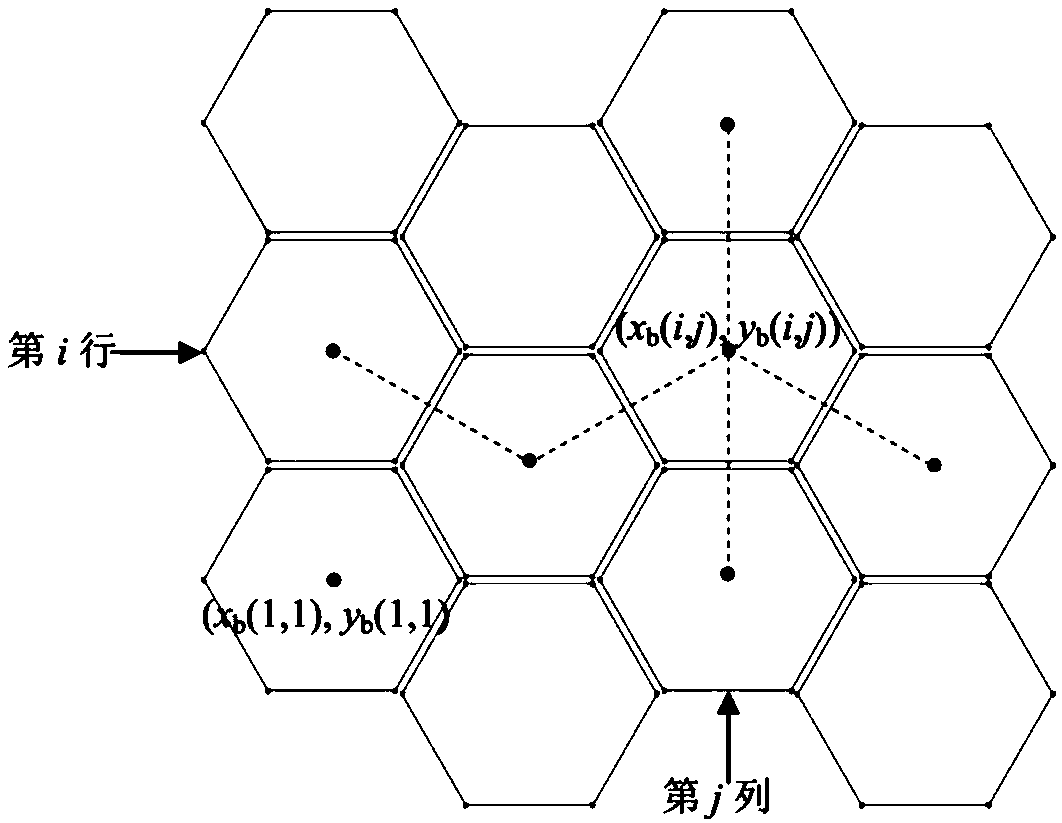

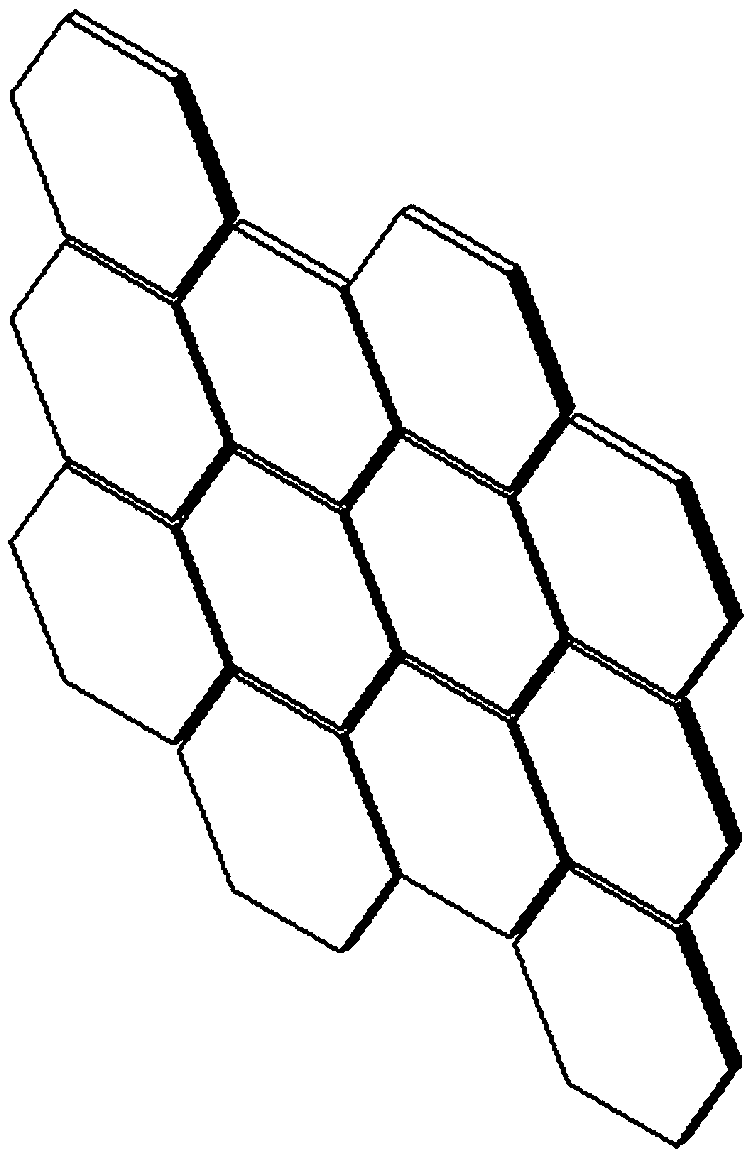

[0035] A parametric modeling method of the imitation mother-of-pearl layered composite board is used for establishing the geometric model and the finite element mesh model of the imitation mother-of-pearl layered composite board. In this embodiment, the mother-of-pearl-like layered composite board uses the mother-of-pearl of the thin-plate "brick-mud" structure as a template, including multi-layer reinforcements, and the layers of reinforcements along the thickness direction of the board (z direction) count as n z . The single-layer reinforcement body includes multiple regular arrays of reinforcement sheets, and the number of reinforcement sheets along the length direction (x direction) and width direction (y direction) of the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com