Segmented closed medium-and-large-section resistive silencer

A resistive muffler and large-section technology, applied in the direction of instruments, sound-producing equipment, etc., can solve the problems of many installation procedures, difficult installation, low product installation efficiency, etc., to control construction quality, improve construction efficiency, and control installation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

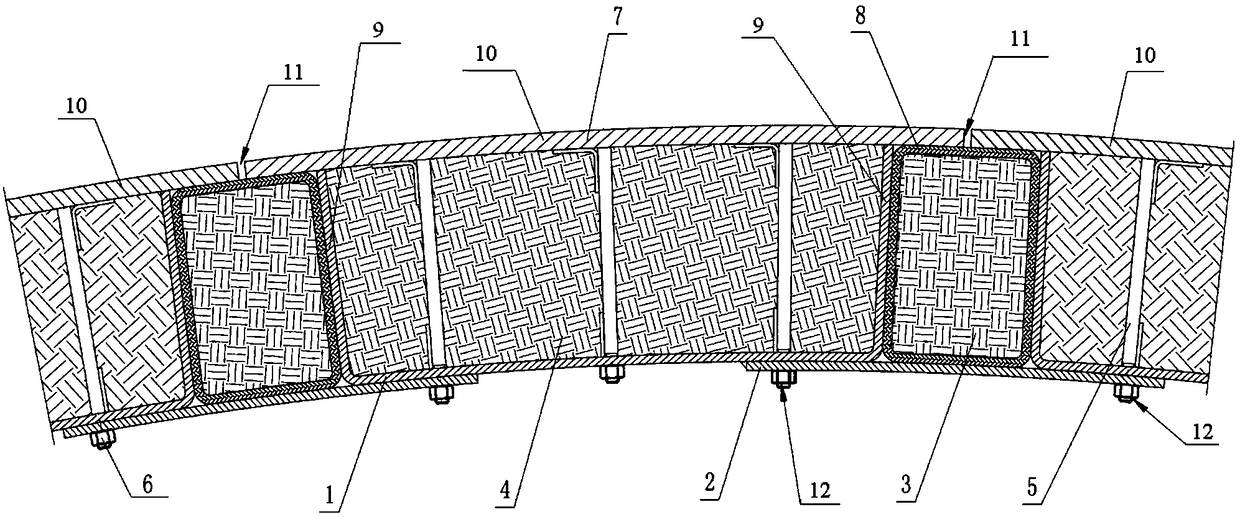

[0015] Specific implementation mode one: combine figure 1 To illustrate this embodiment, this embodiment provides a segmented closed type medium and large cross-section resistive muffler, including: several silencing sections 10, sealing and filling silencing components 3, and inner silencing wall connecting plates 2;

[0016] Each of the sound-absorbing sections 10 includes an outer sound-absorbing wall 7 and an inner sound-absorbing wall 1; the inner sound-absorbing wall 1 is arranged opposite to the outer sound-absorbing wall 7, and is fixedly connected with the outer sound-absorbing wall 7 by a plurality of sound-absorbing wall fastening nails 5; the outer sound-absorbing wall The width of 7 is greater than the inner sound-absorbing wall 1, and the two ends of the inner sound-absorbing wall 1 are respectively extended to the outer sound-absorbing wall 7 to be shaped on a baffle plate 9; Filled with sound-absorbing filling material 4; the two ends of the outer sound-absorbi...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the sealing and sound-absorbing assembly 3 includes a sound-absorbing material block and a non-metallic sound-absorbing wrapping layer 8 arranged on the surface of the sound-absorbing material block. The prefabricated products of the sealing and sound-absorbing components leave the factory, which is convenient for on-site sealing and installation, effectively avoiding the difficulty of installing sound-absorbing materials on site, and fully ensuring the sound-absorbing quality of the joints of the sound-absorbing sections 10 . At the same time, a non-metallic sound-absorbing wrapping layer 8 is arranged outside the sound-absorbing material block to form a closed structure, which ensures the use function and life of the product.

[0023] Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the gap between the baffle plate 9 and the outer sound-absorbing wall 7 is 8-12 mm. Since the baffle 9 needs to be surrounded by the outer silencing wall 7 and the inner silencing wall 1 to form a closed space for filling the silencing filling material 4 and other internal vulnerable silencing components, the baffle 9 needs to be close to the outer silencing wall 7; however, When the temperature of the flue gas inside the flue gas channel where the muffler is located is higher than 200°C, the muffler will pass the internal smoke temperature to the outer sound-absorbing wall 7 through the baffle 9. Keep a certain gap between them; in this embodiment, the gap is set to 8mm to 12mm, which can not only ensure that when the internal flue gas temperature is high, it can prevent the heat transfer of the smoke temperature to the outer sound-absorbing wall 7, but also ensure the closure of the sound-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com