A kind of hard carbon material and preparation method thereof

A hard carbon and raw material technology, applied in the preparation/purification of carbon, structural parts, electrical components, etc., can solve the problems that affect the practical process of hard carbon materials, small lithium intercalation capacity and reversible capacity, and irregular layer structure. , to achieve good large-scale application potential, improved electrochemical performance, and good high-power discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Its preparation method of hard carbon material of the present invention may further comprise the steps:

[0025] In the first step, the raw materials are initially fired, and the rice is heated in a steam heating furnace under an incomplete N2-protected reducing atmosphere at a temperature of 400-600°C and a heating time of 5-10 minutes to obtain a precursor.

[0026] The second step is coarse crushing, and the precursor is crushed to an average particle diameter of 5-50 μm.

[0027] The third step is carbonization. Under the protection of an inert atmosphere, the above pulverized material is coated with bincho carbon, and then reduced at a high temperature of 1000-1500 ° C for 1-20 hours.

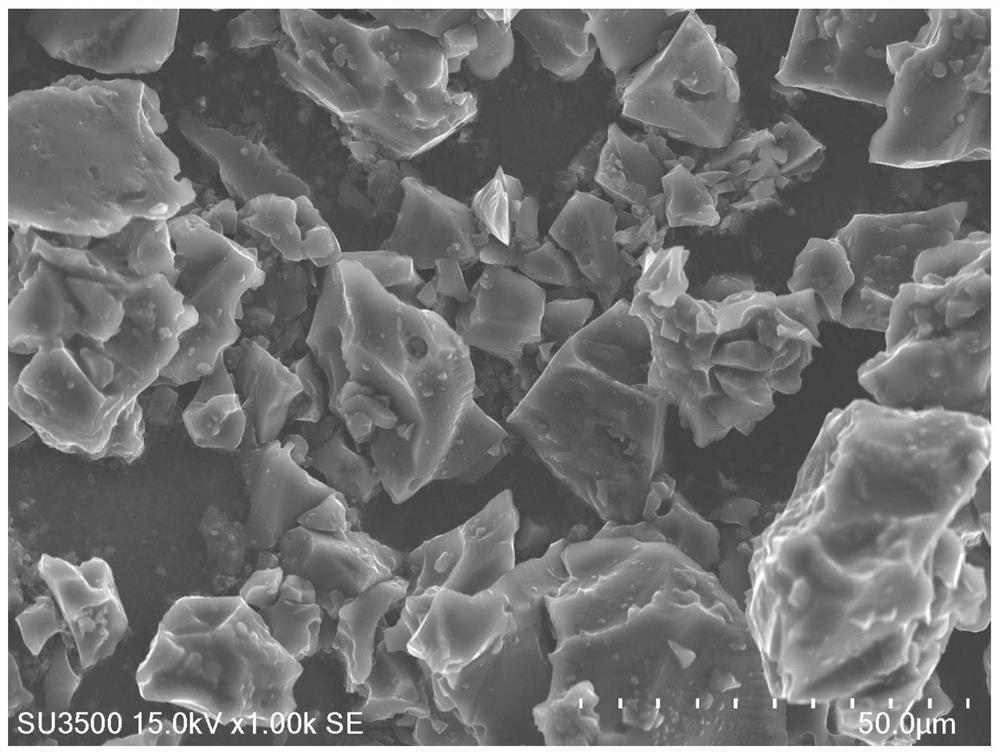

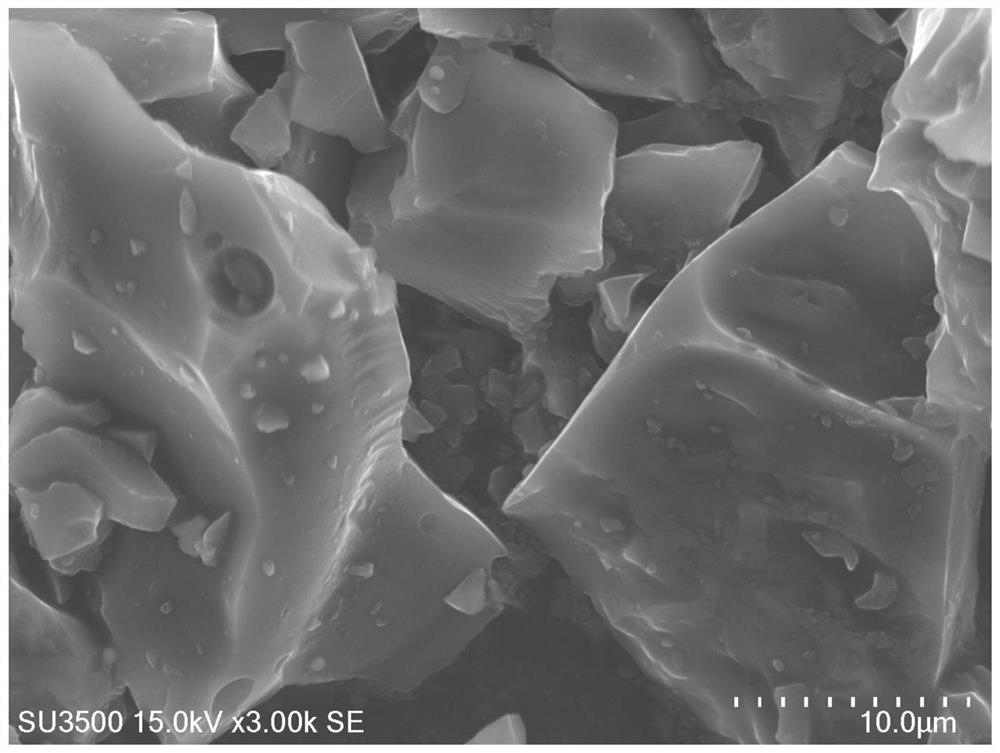

[0028] The fourth step is fine pulverization, pulverizing the above-mentioned carbonized material, and the average particle diameter is about 10 μm. Through pulverization and micronization, the particle size of the material can be fine and uniform.

[0029] The fifth step is class...

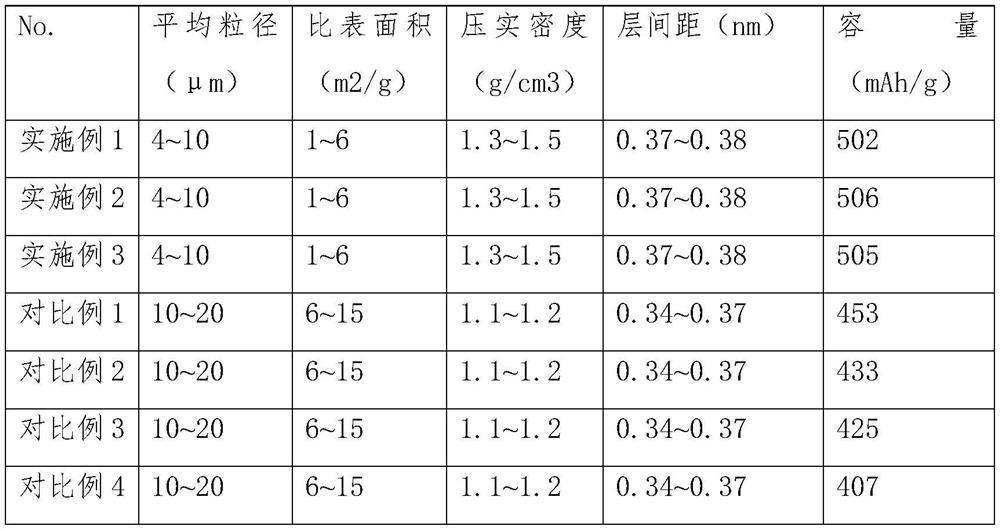

Embodiment 1

[0034] The rice was heated in a steam heating furnace under a reducing atmosphere protected by incomplete nitrogen at a temperature of 500°C and a heating time of 7 minutes to obtain a precursor. The precursor is coarsely crushed to an average particle diameter of 5-50 μm. Under the protection of nitrogen in an inert atmosphere, use Bincho charcoal with a hardness between 20-22 degrees, a carbon content between 94-96%, and a carbon element content of 94-96% to cover the above pulverized material, and then reduce it at a high temperature of 1300 ° C. , high-temperature carbonization for 7h to obtain carbonized products. The above-mentioned carbonized material is finely pulverized, and the average particle diameter is about 10 μm. Further pass through an artificial ion-grade crusher and ball mill to a particle size of 4-10 μm.

Embodiment 2

[0036] The rice was heated in a steam heating furnace under a reducing atmosphere protected by incomplete nitrogen at a temperature of 550°C and a heating time of 5 minutes to obtain a precursor. The precursor is coarsely crushed to an average particle diameter of 5-50 μm. Under the protection of argon in an inert atmosphere, use Bincho charcoal with a hardness between 16-18 degrees, a carbon content between 93-95%, and a carbon content of 94-96% to coat the above-mentioned pulverized material, and heat it at 1100 ° C. Reduction, carbonization at high temperature for 15h, to obtain carbonized product. The above-mentioned carbonized material is finely pulverized, and the average particle diameter is about 10 μm. Further pass through an artificial ion-grade crusher and ball mill to a particle size of 4-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com