Inertial stick-slip type cross-scale motion platform

A motion platform and cross-scale technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of high manufacturing cost, complicated manufacturing process, and inability to cross-scale precision Positioning and other issues, to achieve the effect of low manufacturing cost, simple manufacturing process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

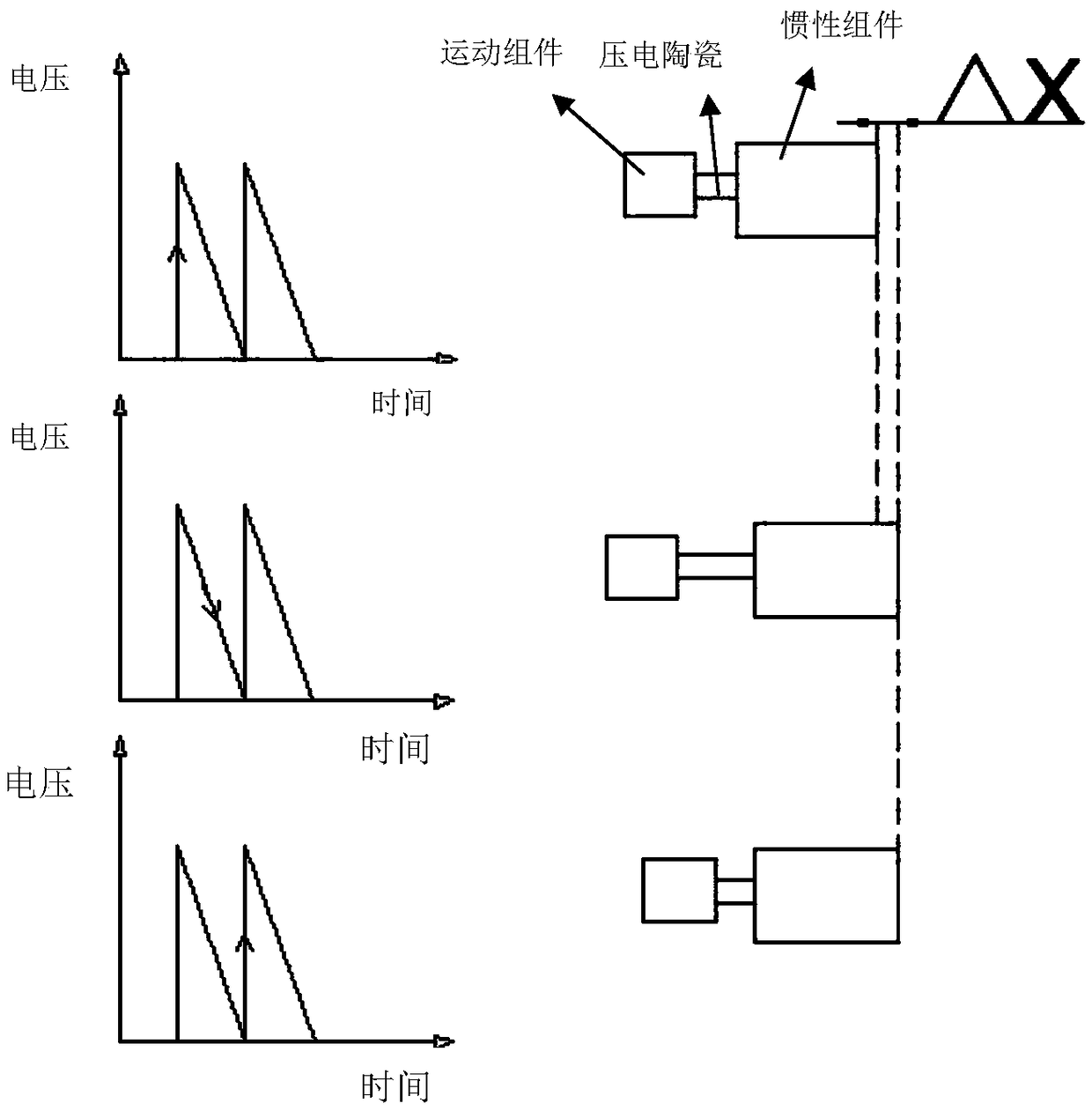

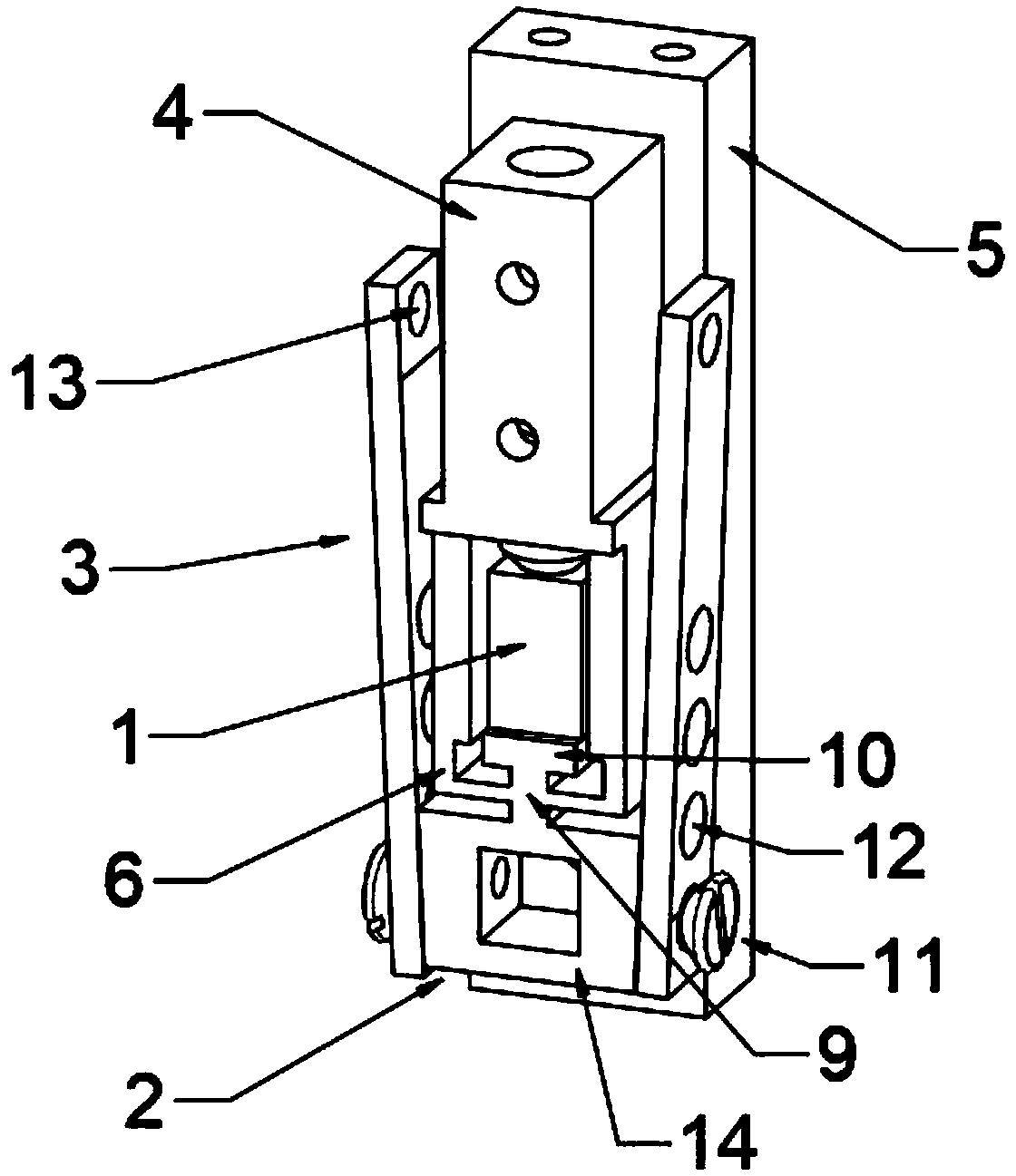

[0026] like figure 1 as shown, figure 1 Schematic diagram of the principle of inertial stick-slip drive. The inertial stick-slip drive system is composed of piezoelectric ceramics, motion components and inertial components. The left side of the figure is the voltage drive signal, and the right side is the motion of the corresponding inertial stick-slip drive system under the drive signal. In the early stage of movement, the driving voltage increases rapidly, and the piezoelectric ceramics elongates rapidly, so that the moving component and the inertial component produce different micro-displacements in opposite directions, and the micro-displacement of the inertial component is △X; when the voltage reaches a certain value , the voltage drops slowly, the piezoelectric ceramic gradually shortens, the inertial component remains in place under the action of friction, and the moving component moves toward the direction of the inertial component. In this way, within one driving cy...

Embodiment 2

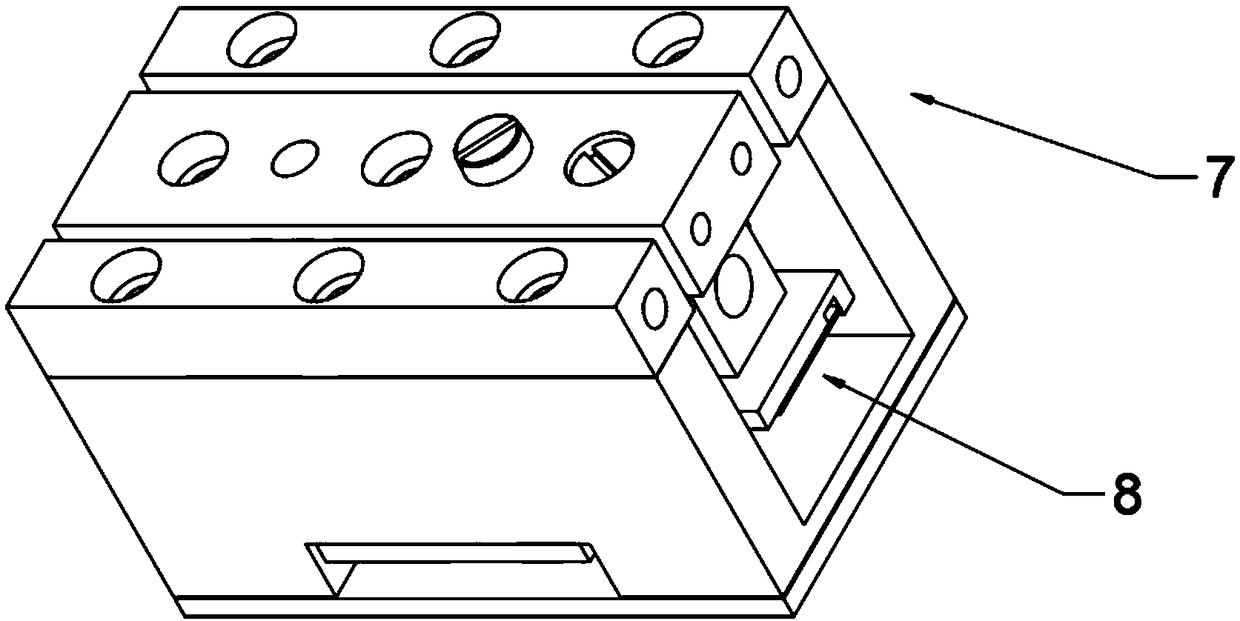

[0036] You can also refer to the appended figure 1 , attached figure 2 And attached image 3The difference between the inertial stick-slip cross-scale motion platform of the second embodiment and the first embodiment is only that a ball is arranged between the elastic arm and the side wall of the protective seat 7, and the ball is arranged on the elastic arm. In the groove 13, the frictional force generated by the contact between the elastic arm and the side wall of the protective seat 7 is a point frictional force, which further reduces the frictional force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com