Complex curved surface adaptive scan induction heating device and method

An induction heating device and complex curved surface technology, applied in the field of heat treatment, can solve the problems of low heating precision, variable curvature, and difficult heat treatment, etc., and achieve the effect of wide application range and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the drawings:

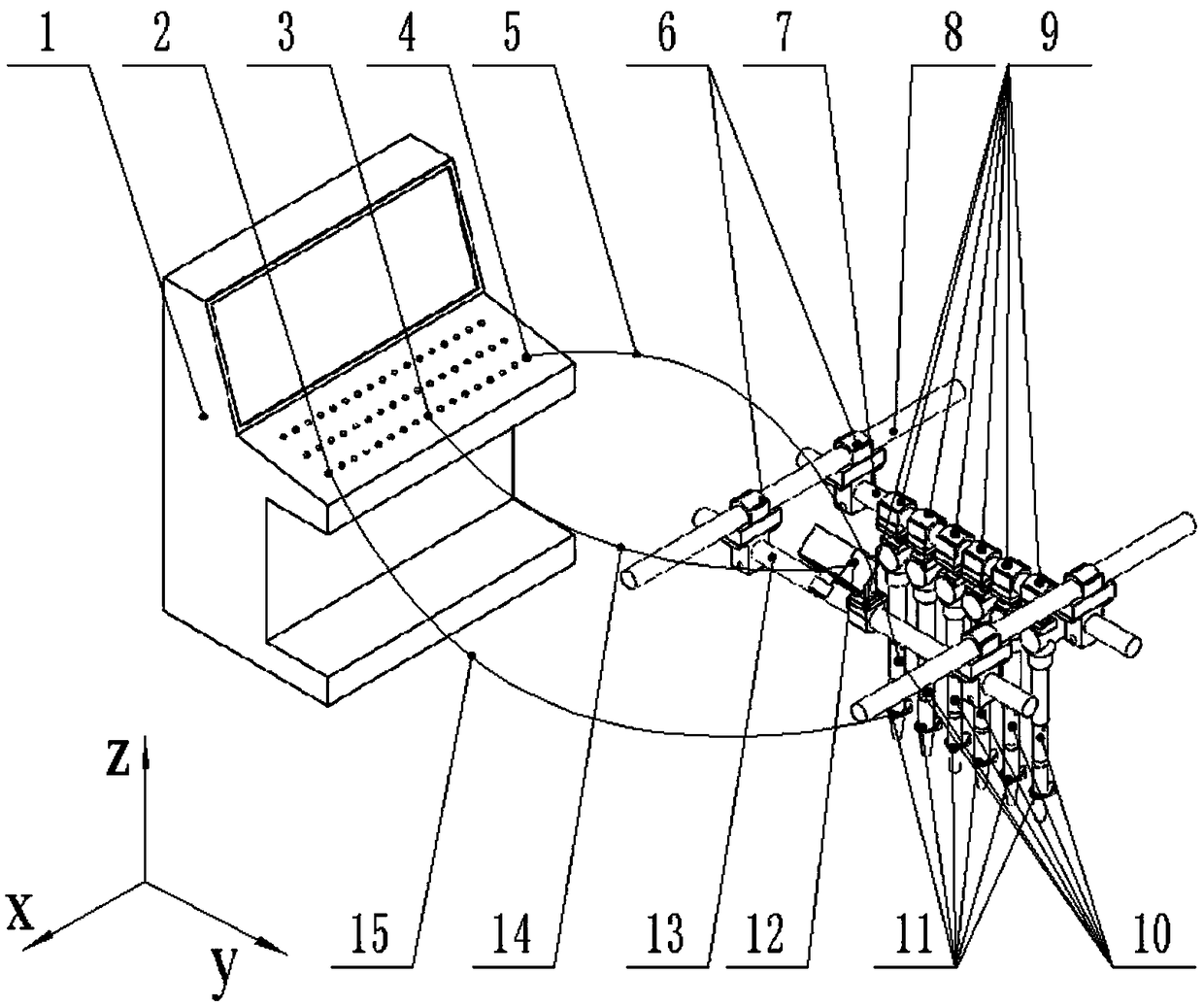

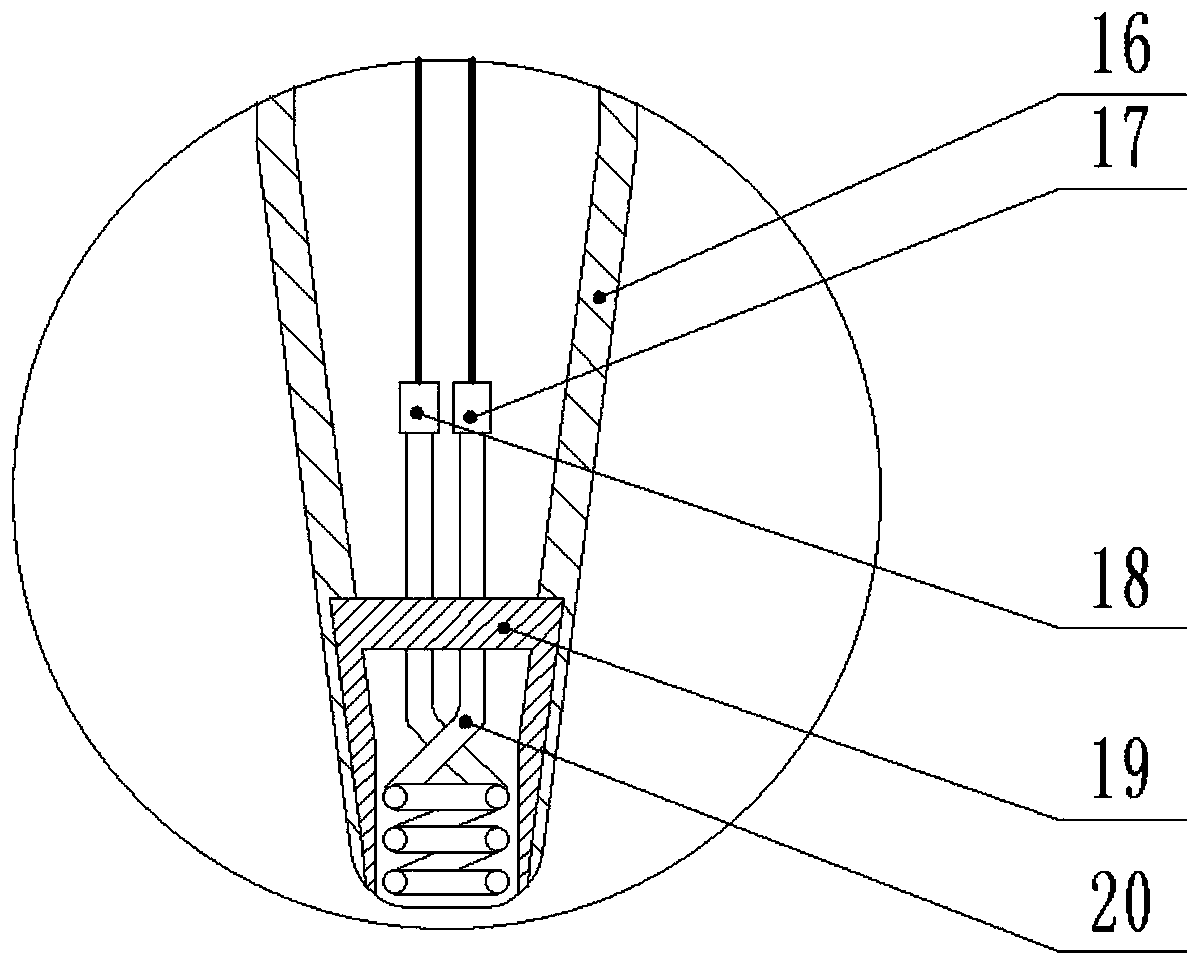

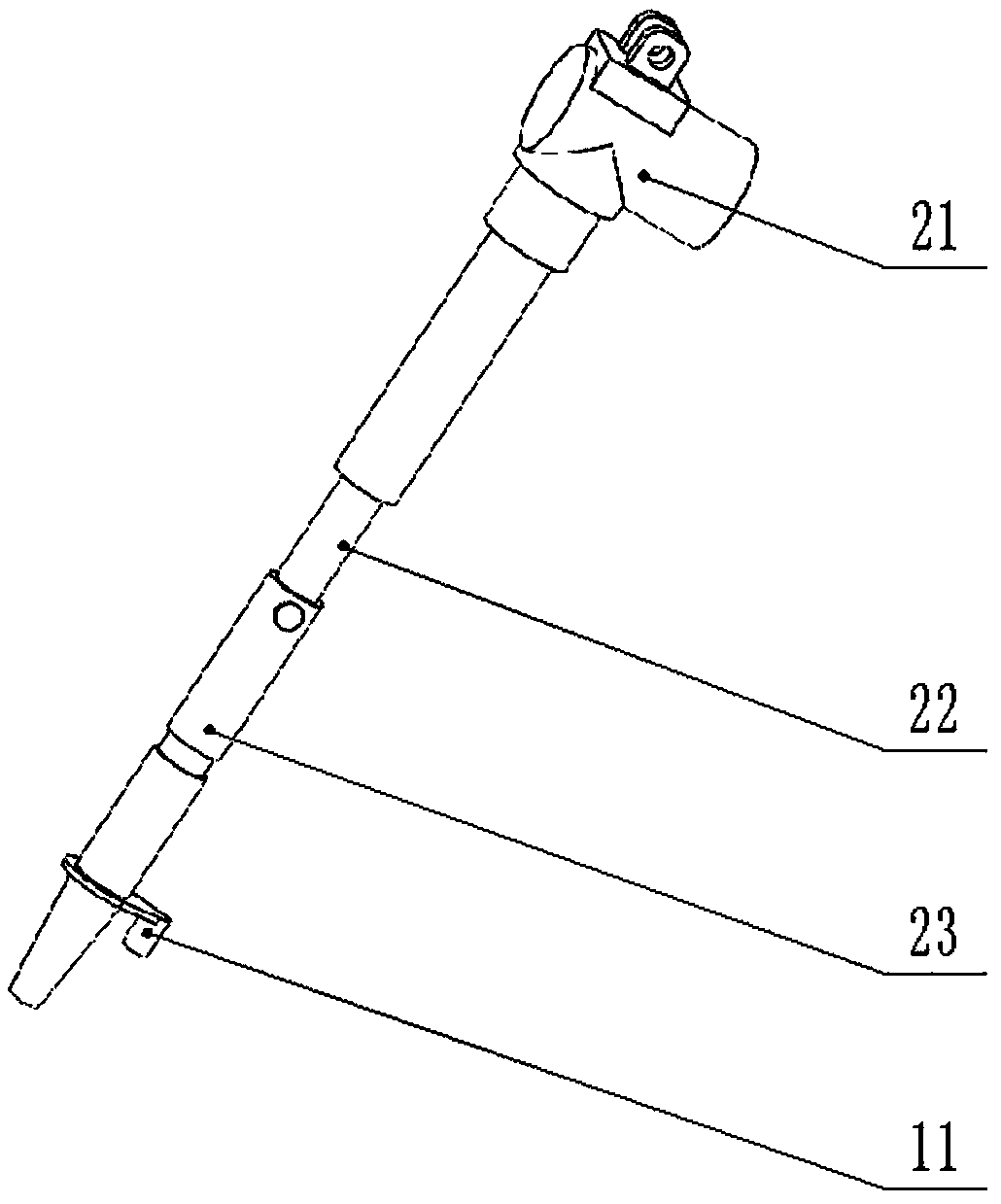

[0032] Such as figure 1 , 2 As shown in 3, the present invention mainly includes a central console 1, a fixed rail 8, a sliding rail I 13, a sliding rail II 7, a temperature sensor 11, a CCD camera 12, a combined probe sensor 10, a slider connecting device I 6, a slider Connecting device II9, the fixed guide rail is composed of two parallel guide rails, the sliding guide rail I and the sliding guide rail II are perpendicular to the two fixed guide rails, and the sliding guide rail I and the sliding guide rail II are respectively connected to the two fixed guide rails through the sliding block connecting device I. "Well"-shaped structure; the CCD camera is installed on the sliding guide I through the slider connecting device II. The CCD camera itself can rotate around the y and z axes and can realize the x and y directions under the action of the slider connecting device II. Move horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com