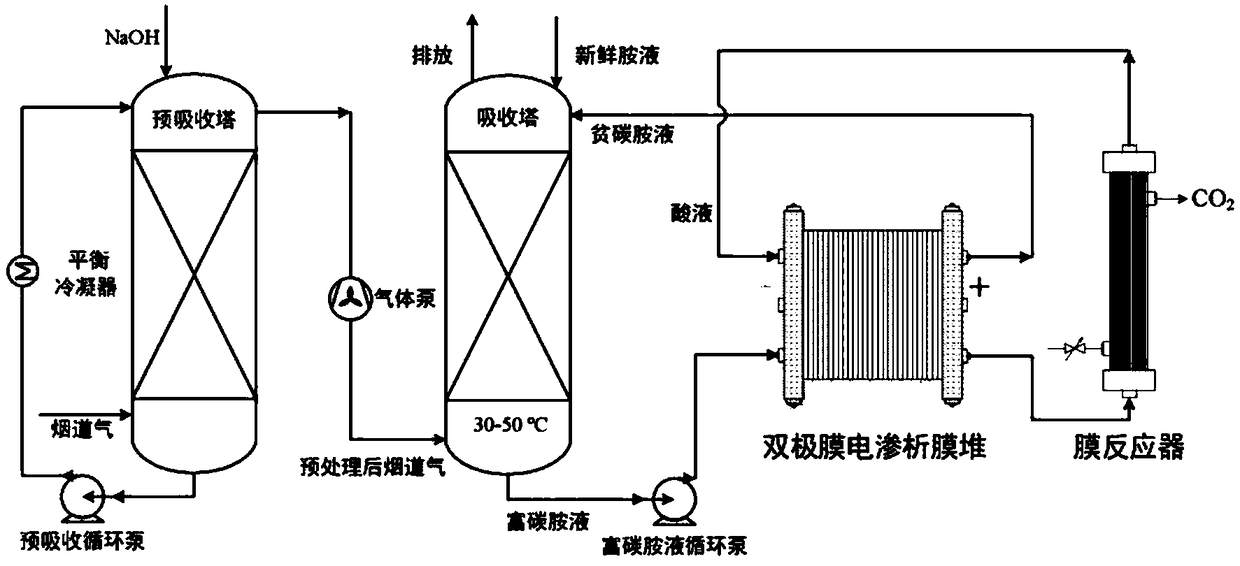

Regeneration system for carbon-rich amine liquid and application thereof

A regeneration system, carbon-rich amine liquid technology, applied in gas treatment, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low feed liquid, increase operation and maintenance costs, high organic amine loss rate, and simplify the process technology route, reduce follow-up maintenance costs, and improve the effect of net capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

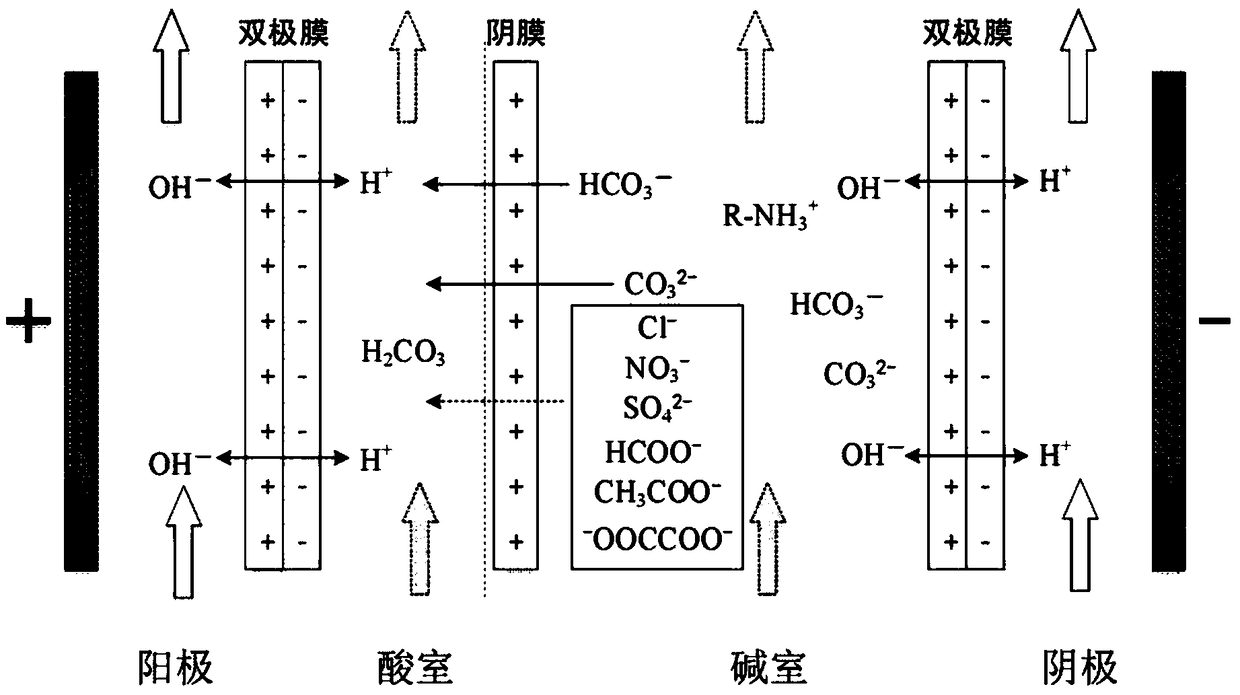

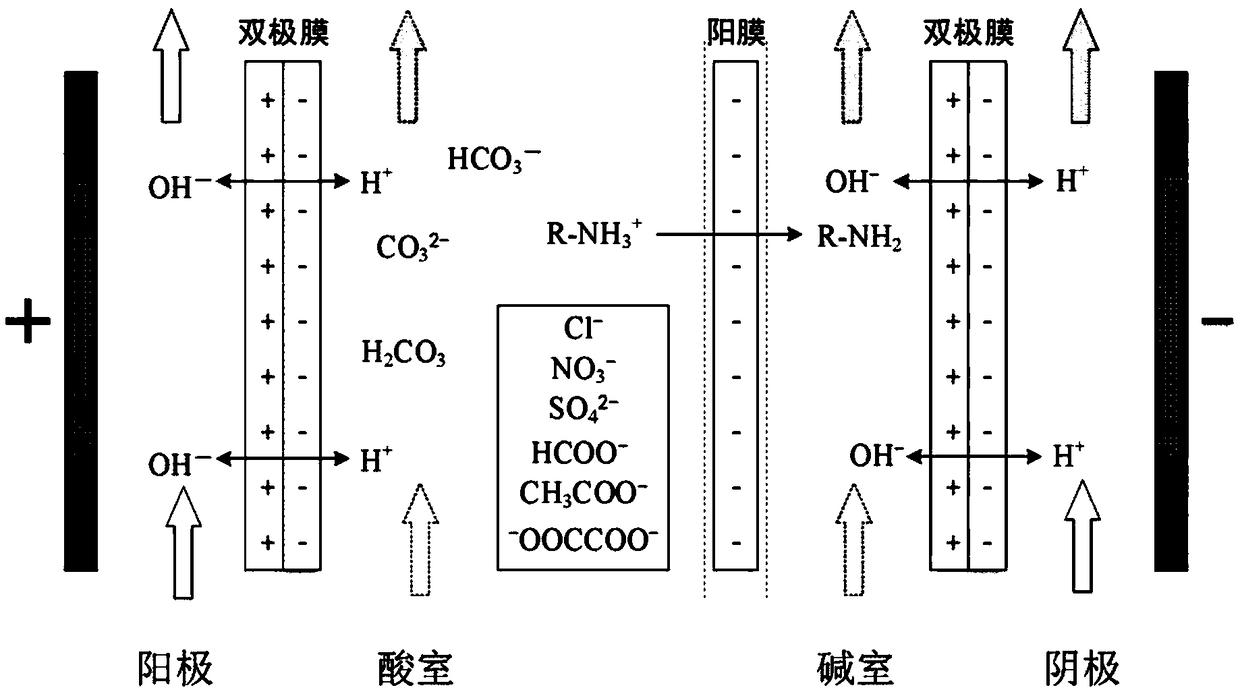

[0066] In the regeneration system used in this example to regenerate the carbon-rich amine liquid carrying thermally stable salts, the bipolar membrane electrodialysis device consists of a bipolar membrane electrodialysis membrane stack fixed between the anode plate and the cathode plate and a carbon dioxide removal In addition to the composition of the device, the bipolar membrane electrodialysis membrane stack used is such as figure 2 The one shown is composed of bipolar membranes and anion exchange membranes laminated alternately and then plus flow channel spacers and sealing gaskets. A total of thirteen bipolar membranes (Neosepta BP-1 purchased from Japan ASTOM Company) and twelve bipolar membranes are used. An anion exchange membrane (Neosepta AMX purchased from Japan ASTOM Company), thus forming 12 repeating units of "alkali chamber-acid chamber" in the bipolar membrane electrodialysis membrane stack; the carbon dioxide removal device adopted is composed of series The ...

Embodiment 2

[0075] The specific operation process is the same as in Example 1, except that the constant current of 2A instead of 1A is applied to the bipolar membrane electrodialysis membrane stack, the results are shown in Image 6 and Figure 7 The results shown in "Monoethanolamine-2A".

Embodiment 3

[0077] Concrete operation process is identical with embodiment 1, just adopts the piperazine aqueous solution of 1mol / L to replace the monoethanolamine solution of 1mol / L as lye, the results see Image 6 and Figure 7 The results shown in "Piperazine-1A".

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap