An automatic robot for partial paint repair of aircraft fuselage

A technology of aircraft fuselage and robot, applied in aircraft maintenance, devices for coating liquid on the surface, coating, etc., can solve problems such as time-consuming, high cost, and shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

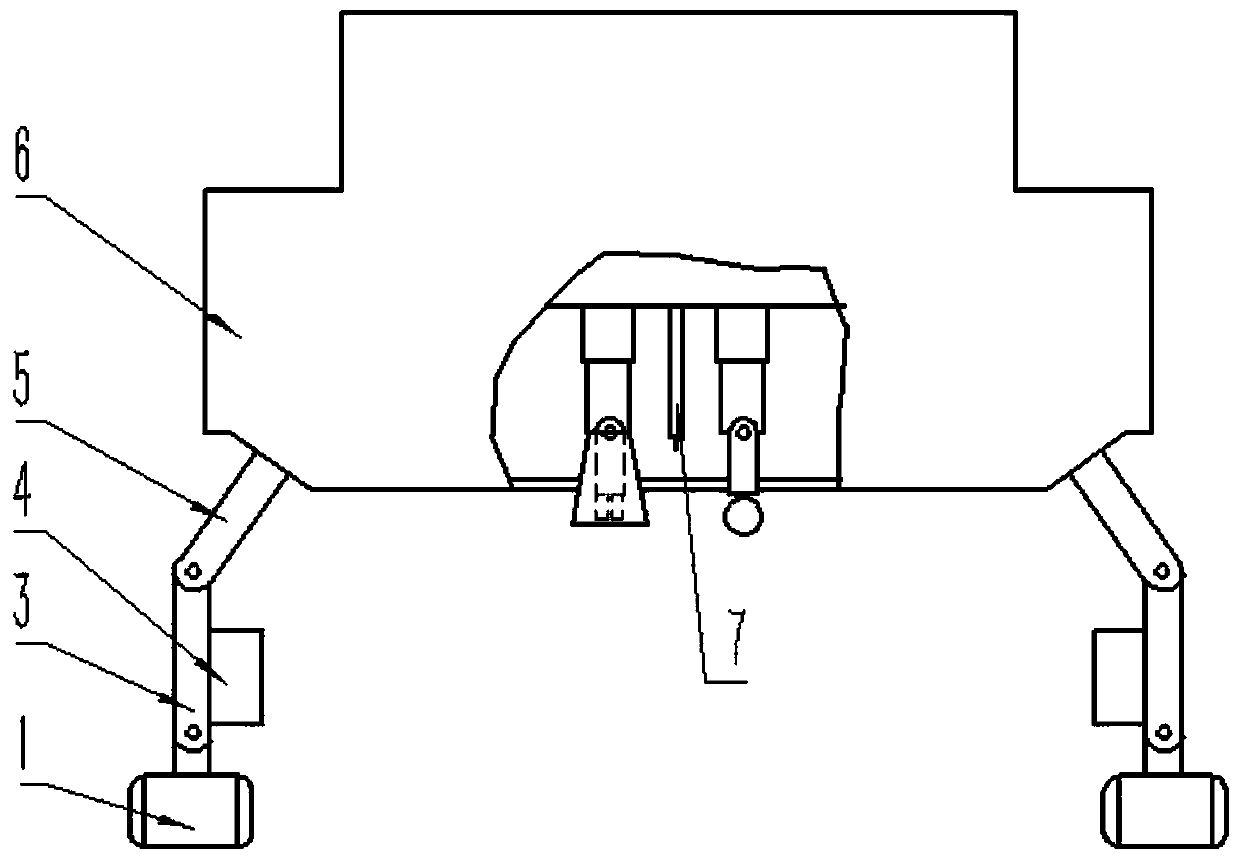

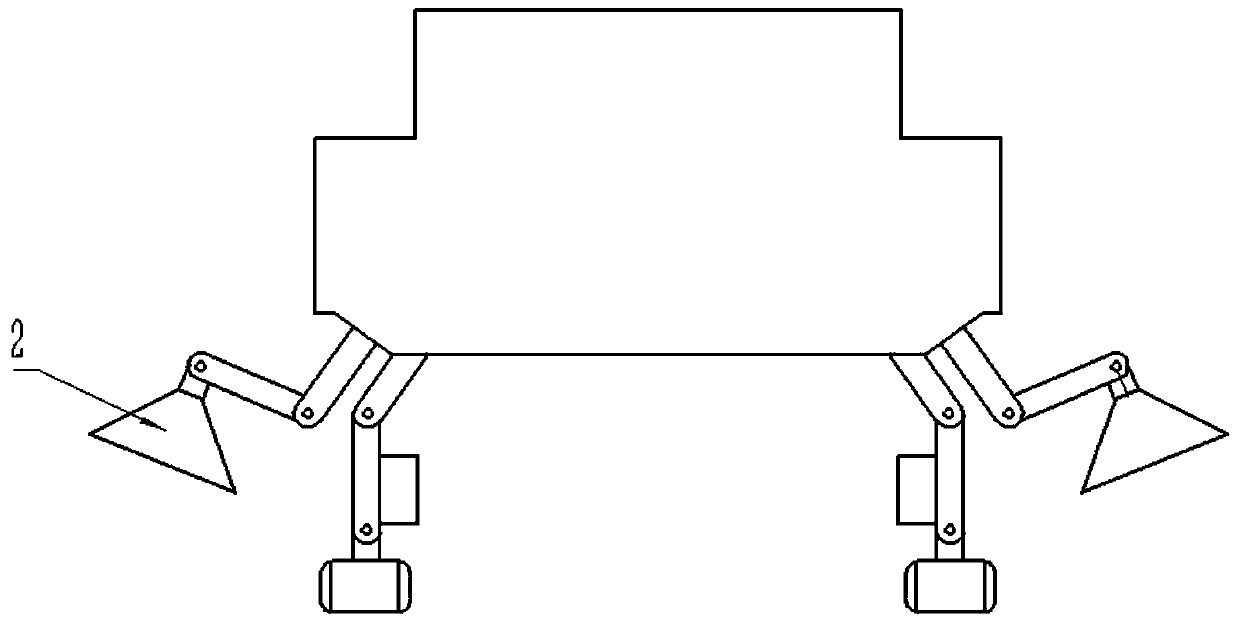

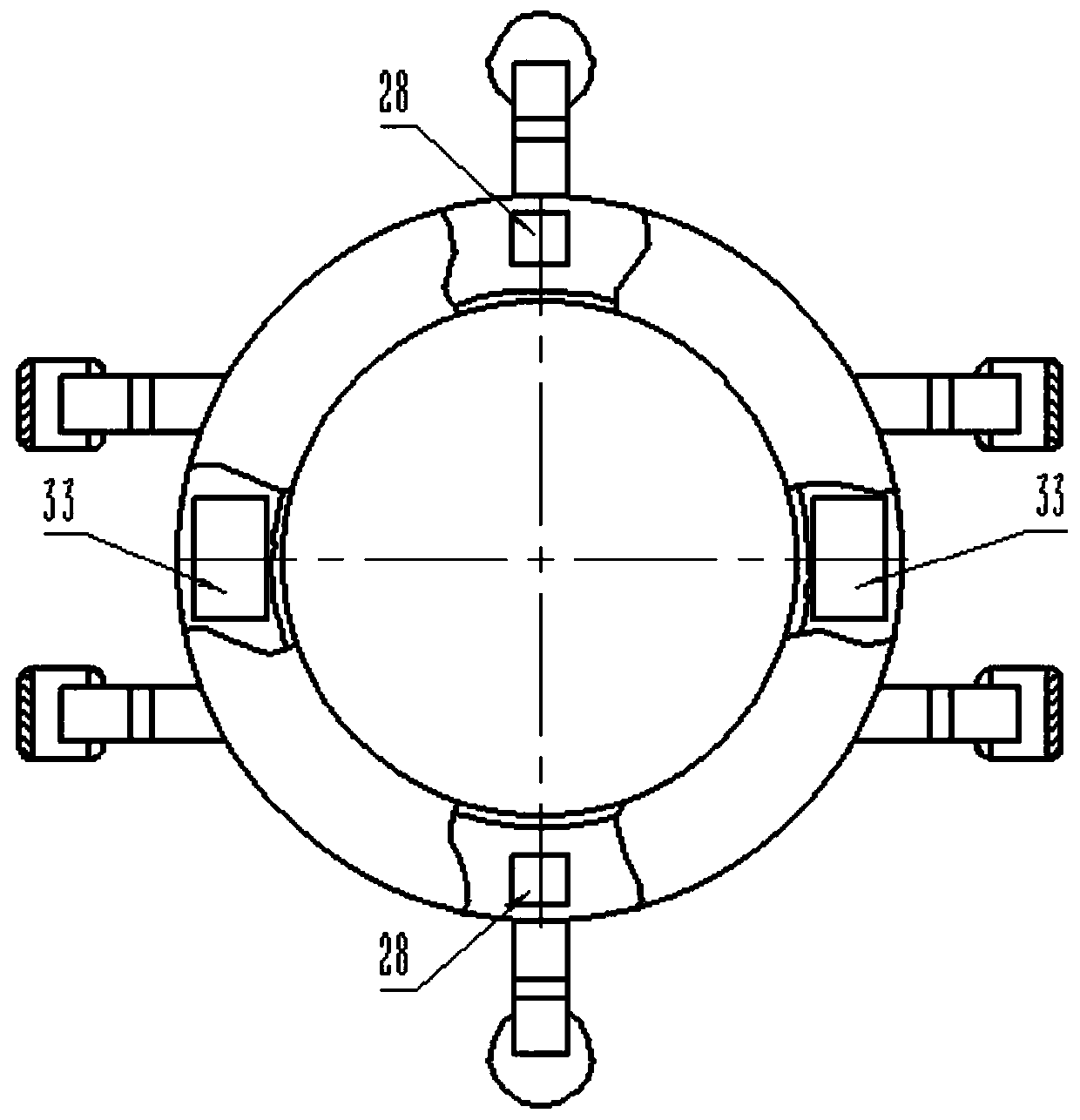

[0024] The present invention is realized through the following technical solutions:

[0025] An automatic robot for partial paint repair of an aircraft fuselage, including a climbing wheel 1, a suction cup 2, outrigger one 3, a speed regulating device 4, outrigger two 5, a chassis 6, a visual device 7, a horizontal slider 8, and a horizontal slider Rail 9, connecting pipe 10, connecting block 11, horizontal transmission rod 12, support plate 13, horizontal power device 14, circumferential transmission device 15, rolling device 16, circumferential rail shell lower plate 17, circumferential rail 18, connecting rod 19 , Circumferential power unit 20, circumferential rail housing 21, rotating slide block 22, telescoping rod 23, rotating arm 24, spray gun 25, spray gun shield 26, grinding device 27, lifting power unit 28, connecting block two 29, elevating rod 30, Connecting rod two 31, protective cover 32, blowing heating device 33, guide ring plate 34, fuselage shell 35, circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com