Method and device for reminding use of heated glue within validity period

A valid period, glue technology, applied in the electronic field, can solve the problems of reducing product quality risk, quality risk, etc., to achieve the effect of reducing product quality risk, avoiding the use of expired glue, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for reminding the glue to be used within the validity period after returning to temperature, which is applied to electronic equipment. Specifically, the electronic equipment can be: an industrial computer connected to the dispensing equipment, or a smart phone, or a tablet computer, etc. etc. This embodiment does not specifically limit what kind of device the electronic device is. In addition, the method can be run in a Windows system or a DOS system in the form of program code.

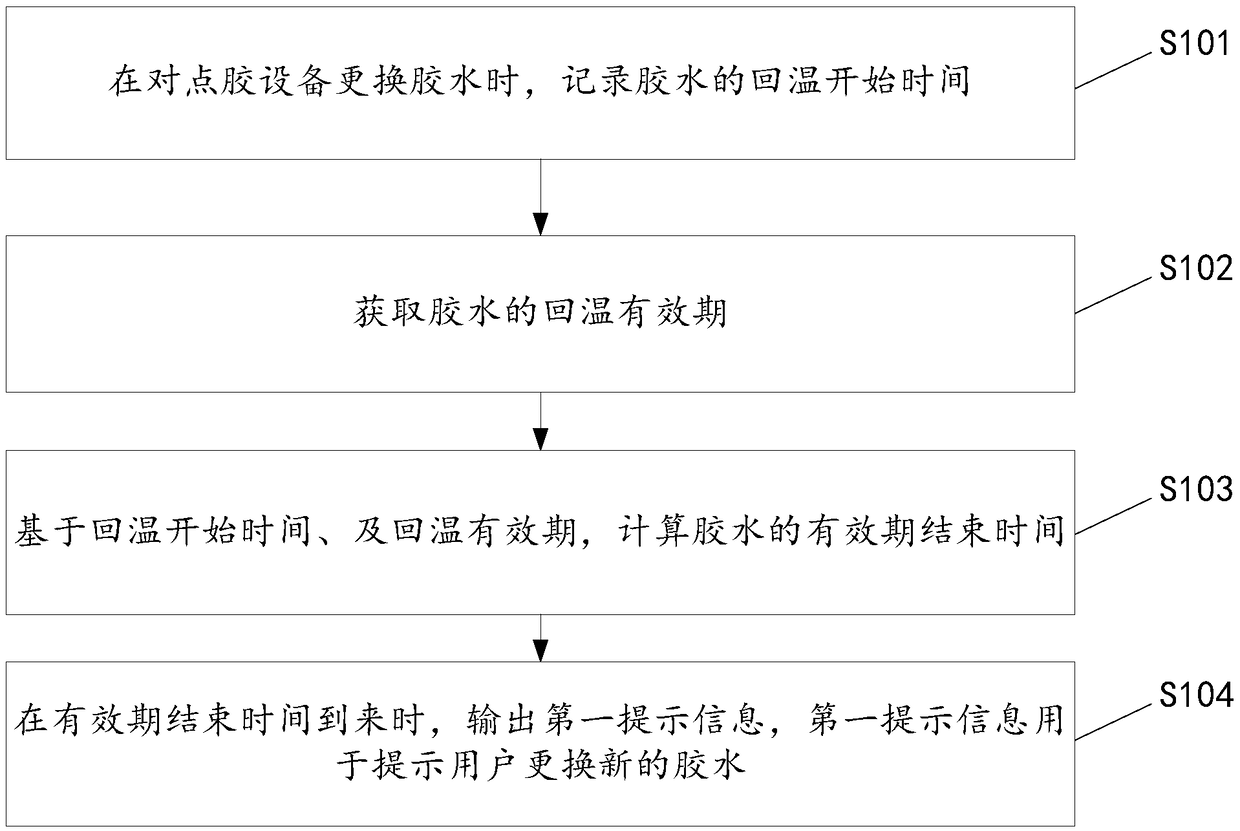

[0052] Specifically, if figure 1 As shown, the method for reminding the glue to be used within the validity period after returning to temperature includes:

[0053] Step S101: When replacing the glue on the glue dispensing device, record the starting time of the glue's temperature recovery.

[0054] In the specific implementation process, the glue dispensing equipment is used for dispensing glue for the product, wherein the product can be a camera module pro...

Embodiment 2

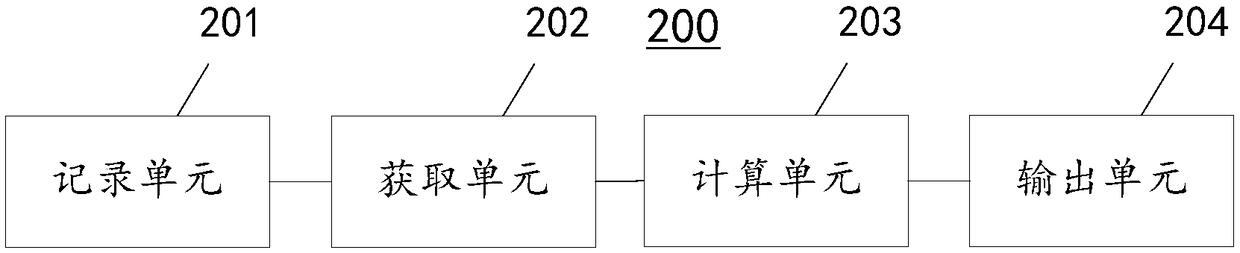

[0089] Based on the same inventive idea, such as figure 2 As shown, this embodiment provides a device 200 for reminding the glue to be used within the validity period after returning to temperature, including:

[0090] The recording unit 201 is used to record the temperature return start time of the glue when the glue is replaced by the glue dispensing equipment;

[0091] An acquisition unit 202, configured to acquire the warm-up validity period of the glue;

[0092] Calculation unit 203, configured to calculate the end time of the validity period of the glue based on the start time of the temperature recovery and the validity period of the temperature recovery;

[0093] The output unit 204 is configured to output first prompt information when the expiry time of the validity period arrives, and the first prompt information is used to prompt the user to replace with new glue.

[0094] As an optional embodiment, the obtaining unit 202 is specifically configured to:

[0095] ...

Embodiment 3

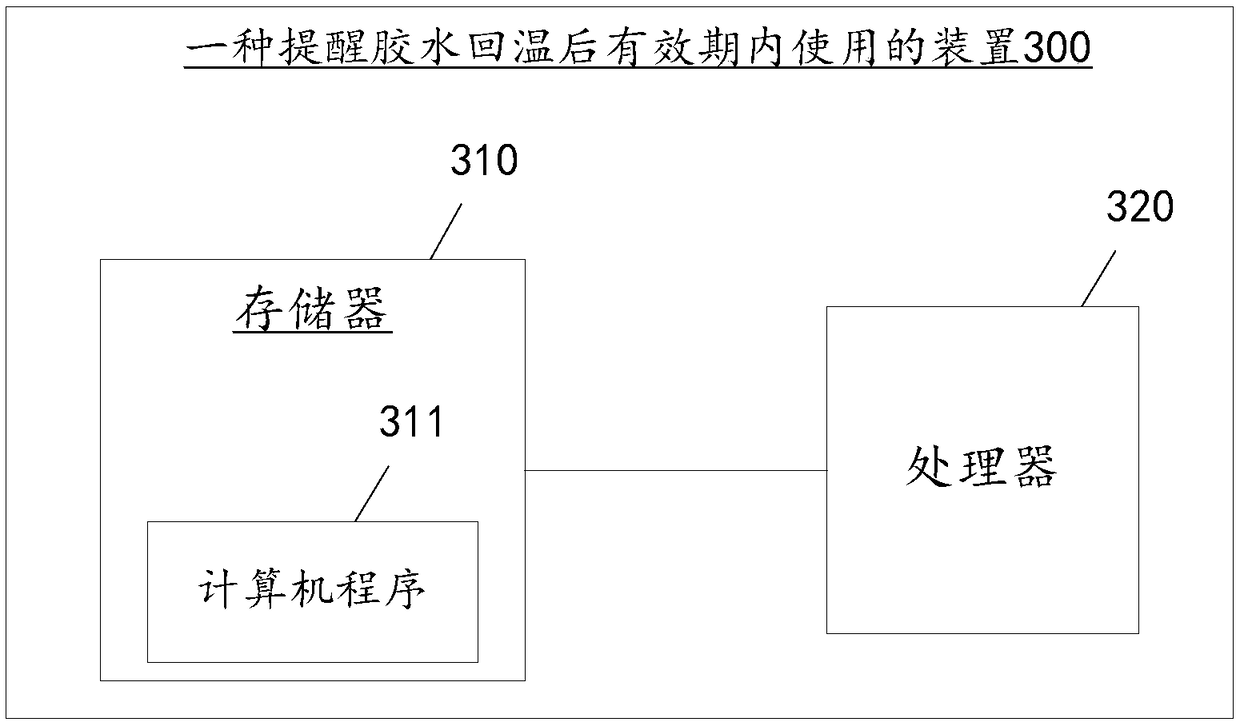

[0106] Based on the same inventive idea, such as image 3 As shown, the present embodiment provides a device 300 for reminding glue to be used within the validity period after returning to temperature, including a memory 310, a processor 320, and a computer program stored on the memory 310 and operable on the processor 320, the processing When the device 320 executes the computer program, the following steps are implemented:

[0107] When replacing the glue on the dispensing equipment, record the temperature recovery start time of the glue; obtain the temperature recovery validity period of the glue; calculate the end of the validity period of the glue based on the temperature recovery start time and the temperature recovery validity period Time: when the end of the validity period arrives, output first prompt information, and the first prompt information is used to prompt the user to replace with new glue.

[0108] As an optional embodiment, the acquisition of the return tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com