A crankshaft riser method that is easy to fall off and requires no grinding

A non-grinding, crankshaft technology, applied in the direction of casting molding equipment, metal processing equipment, casting mold components, etc., can solve the problems of easily damaged crankshaft castings, time-consuming, etc., to achieve automatic shedding, easy to avoid grinding, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

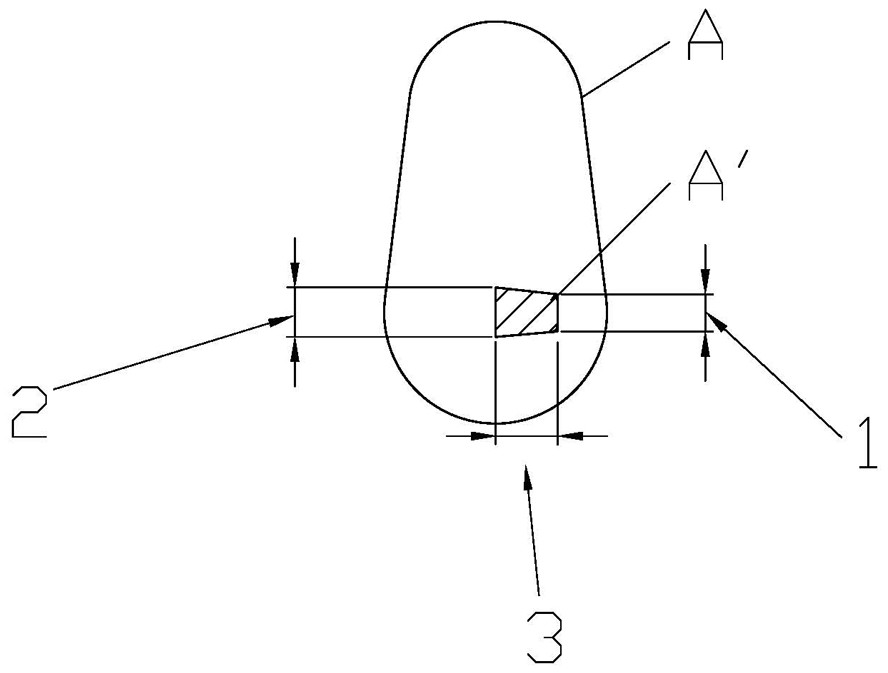

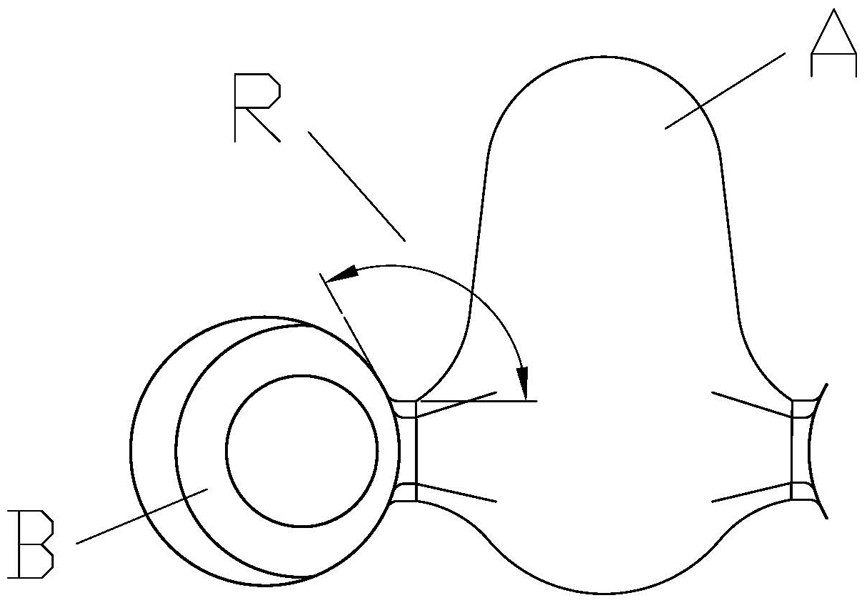

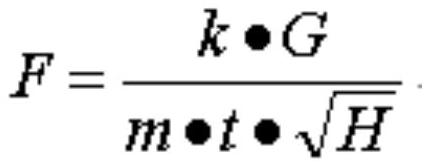

[0038] ①The weight of the crankshaft casting A is 0.21kg. After calculating through the pouring system formula, the required interception area is 35mm 2 ;

[0039] ②The shape of the riser neck is isosceles trapezoid, the lower bottom is 6mm, the upper bottom is 4mm, and the height is 7mm;

[0040] ③ The angle between the riser neck and the casting is designed to be 100°.

[0041] Tracking during production, after the crankshaft casting A passed through the drum and shot blasting, the riser was completely separated from the casting, and 10 pieces were taken to measure the residual height of the riser. The results are as follows:

[0042] 0.51mm, 0.34mm, 0.52mm, 0.70mm, 0.28mm, 0.34mm, 0.48mm, 0.66mm, 0.53mm, 0.47mm, the residual height is less than 0.76mm, no need for manual grinding.

Embodiment 2

[0044] X crankshaft:

[0045] ①The weight of the crankshaft casting X is 0.45kg. After calculation by the pouring system formula, the required area is about 70mm 2 ;

[0046] ②The shape of the riser neck is isosceles trapezoid, the lower bottom is 8mm, the upper bottom is 6mm, and the height is 10mm;

[0047] ③ The angle between the riser neck and the casting is designed to be about 120°.

[0048] Tracking during production, after the crankshaft casting X passed through the drum and shot blasting, the riser was completely separated from the casting, and 10 pieces were taken to measure the residual height of the riser. The results are as follows:

[0049] 0.37mm, 0.16mm, 0.61mm, 0.58mm, 0.32mm, 0.26mm, 0.45mm, 0.26mm, 0.33mm, 0.33mm, the residual height is less than 0.76mm, no need for manual grinding.

Embodiment 3

[0051] BE crankshaft: Relevant parts of riser neck in process design:

[0052] ①The weight of the crankshaft casting BE is 0.46kg. After calculation by the pouring system formula, the required area is about 71mm 2 ;

[0053] ②The shape of the riser neck is isosceles trapezoid, the lower bottom is 8mm, the upper bottom is 6mm, and the height is 10mm;

[0054] ③ The angle between the riser neck and the casting is designed to be about 107°.

[0055] Tracking during production, after the crankshaft casting BE passed through the drum and shot blasting, the riser was completely separated from the casting, and 10 pieces were taken to measure the residual height of the riser. The results are as follows:

[0056] 0.41mm, 0.45mm, 0.59mm, 0.46mm, 0.13mm, 0.56mm, 0.68mm, 0.59mm, 0.57mm, 0.35mm, the residual height is less than 0.76mm, no need for manual grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com