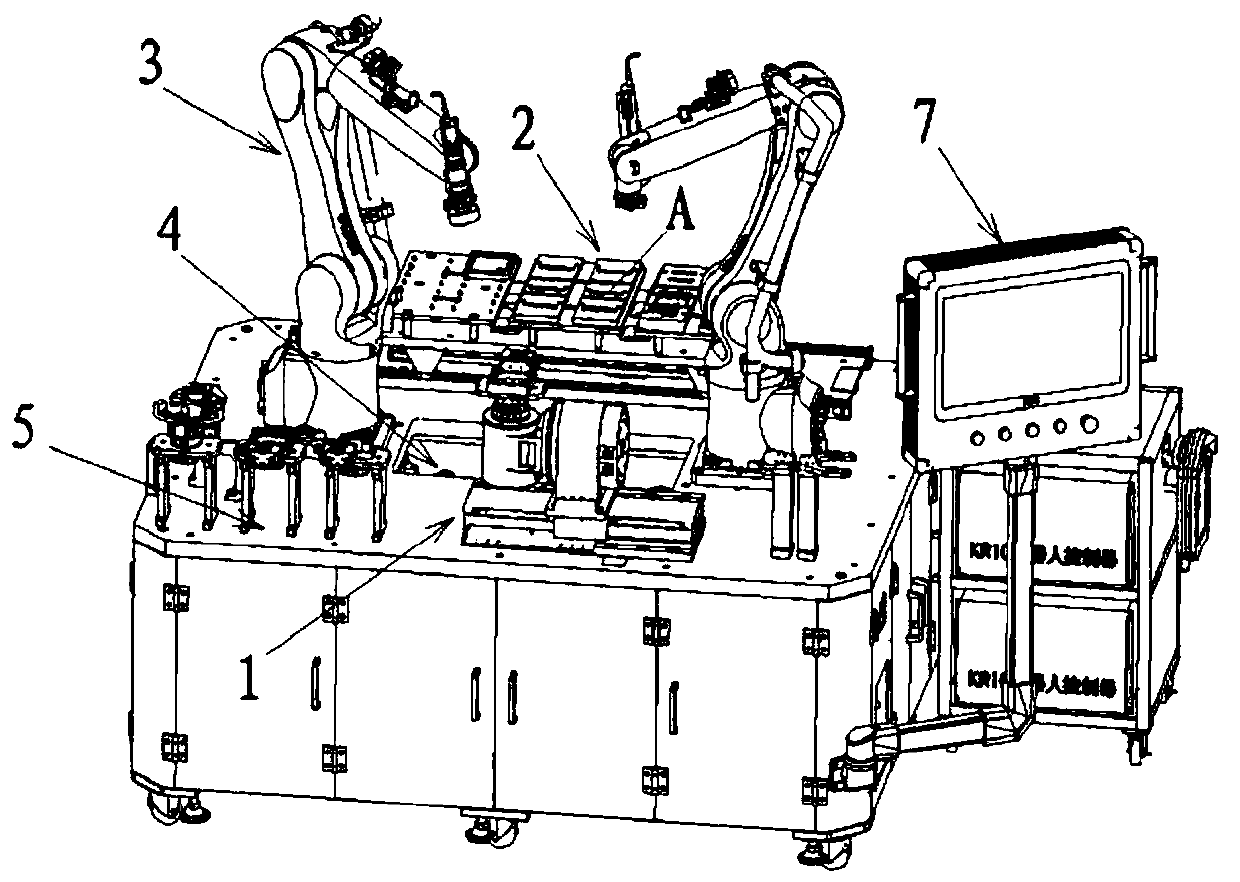

Assembly system

An assembly system and assembly tooling technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor generality of the assembly system, and achieve the effect of improving efficiency, saving moving distance, and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

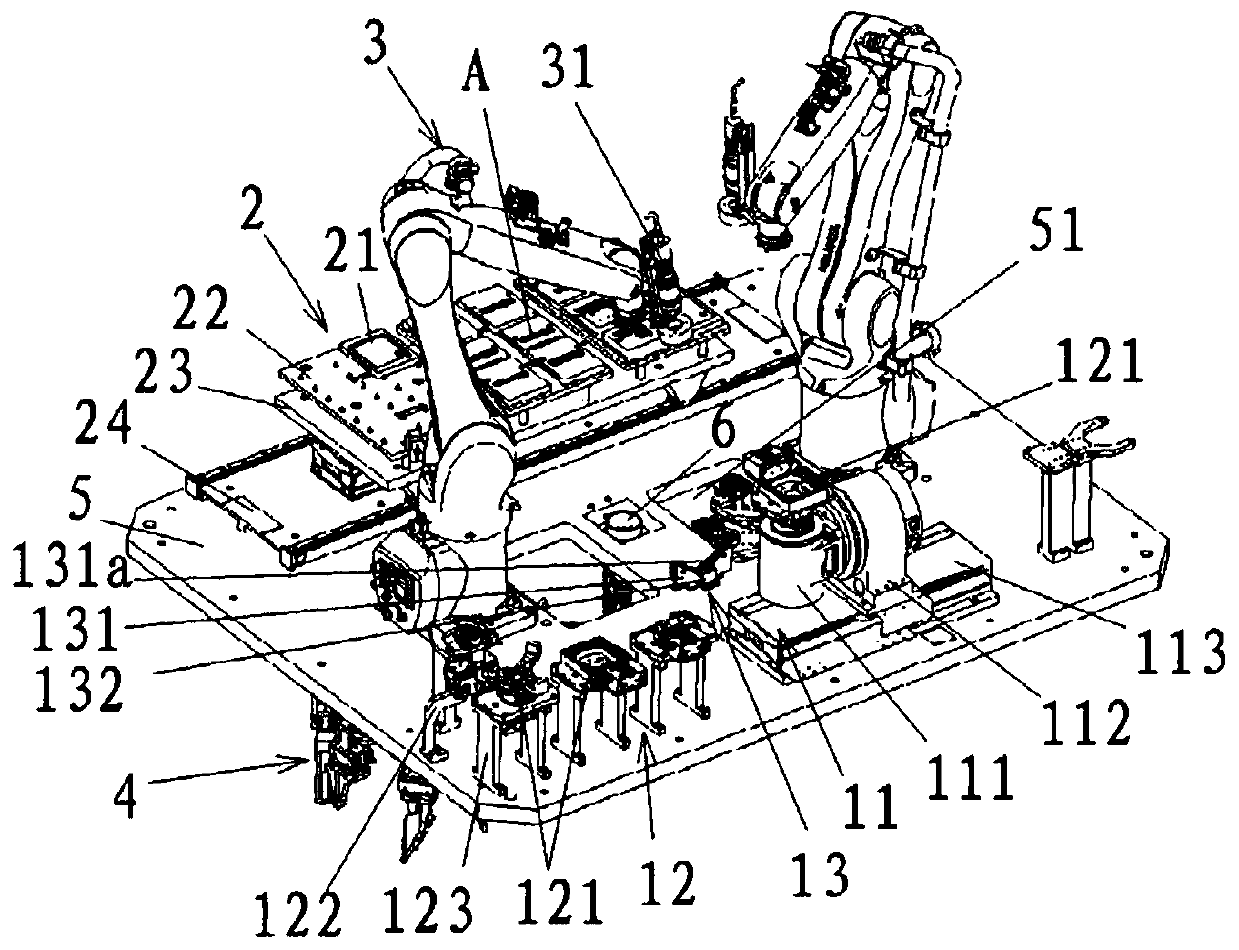

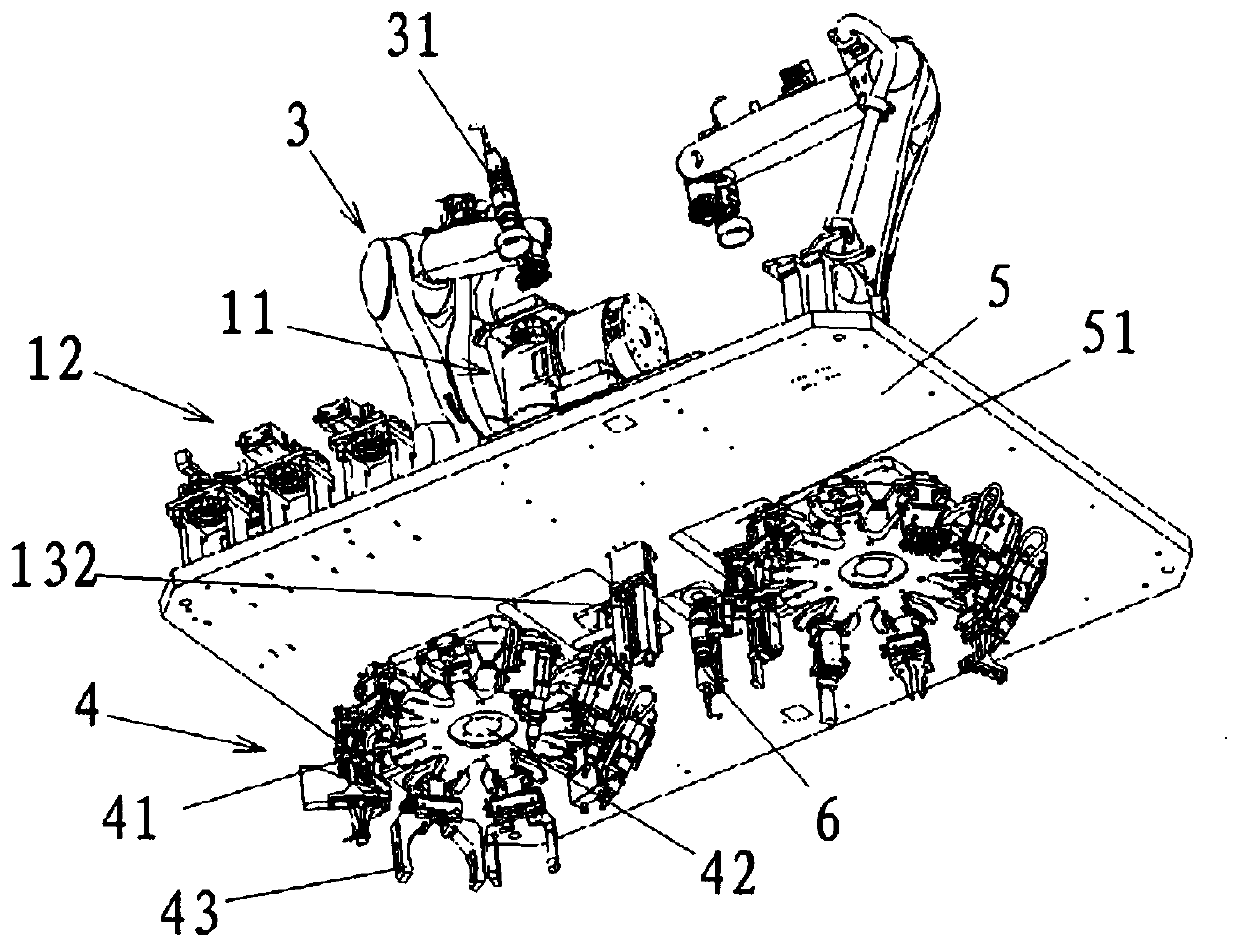

[0066] combine figure 2 and Figure 4 As shown, according to an embodiment of the present invention, the clamping tool warehouse 12 includes: a clamping tool 121 , a handling tool 122 and a supporting frame 123 . In this embodiment, the clamping tool 121 and the transporting tool 122 are respectively supported on corresponding supporting frames 123 . At least one clamping tool store 12 is provided, and there is at least one clamping tool 121 in the clamping tool storehouse 12, and the number of clamping tools 121 can be two, three or more. The clamping tool 121 is detachably connected to the rotation shaft of the first rotation mechanism 111 . The execution unit 3 can place the clamping tool 121 in the clamping tool warehouse 12 on the rotation axis of the first rotating mechanism 111 through the transport tool 122 . The rotation of the clamping tool 121 can be realized by the first rotating mechanism 111, the adjustment of the pitch angle of the clamping tool 121 can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com