Bearing track superfinishing swing head capable of achieving monitoring of using state of oilstone

A technology of bearing raceway and oilstone, applied in the field of ultra-precision swinging head of bearing raceway, can solve the problems of wasting energy, failure to purchase and provide obvious data support, jamming, etc., and achieve the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

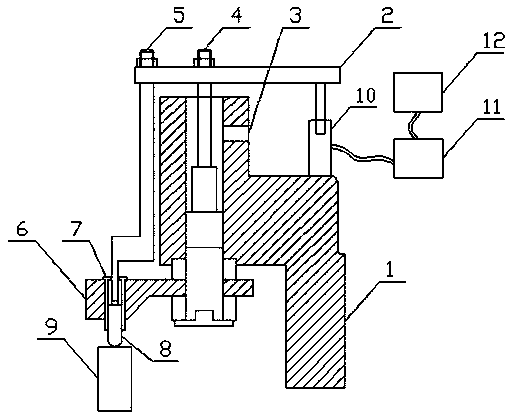

[0016] Such as figure 1 The shown bearing raceway ultra-precision swing head that can monitor the use status of the oil stone includes: a swing head base 1 with a cavity, and a piston mechanism is installed in the cavity of the swing head base 1, and the piston mechanism includes a piston And the piston rod 4, one end of the piston rod 4 is connected with the piston, and the other end extends out of the inner cavity of the swing head base 1 and is vertically connected with the balance weight 2; The pressurized air intake hole 3; along the bottom of the inner cavity of the swing head base 1, the whetstone clamp base 6 is connected; the whetstone clamp base 6 is provided with the whetstone clamp 7 for installing the whetstone 8, and the whetstone clamp 7 is provided above the whetstone clamp 7. The whetstone pressure rod 5 that squeezes the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com